Alpha brass primarily consists of copper and zinc with zinc content up to 35%, offering excellent ductility and corrosion resistance ideal for applications requiring good formability. Beta brass contains higher zinc levels, typically between 45% and 50%, providing greater strength and hardness but reduced ductility, making it suitable for machining and high-strength components. Understanding the differences in composition and mechanical properties helps in selecting the right brass alloy for specific engineering and manufacturing needs.

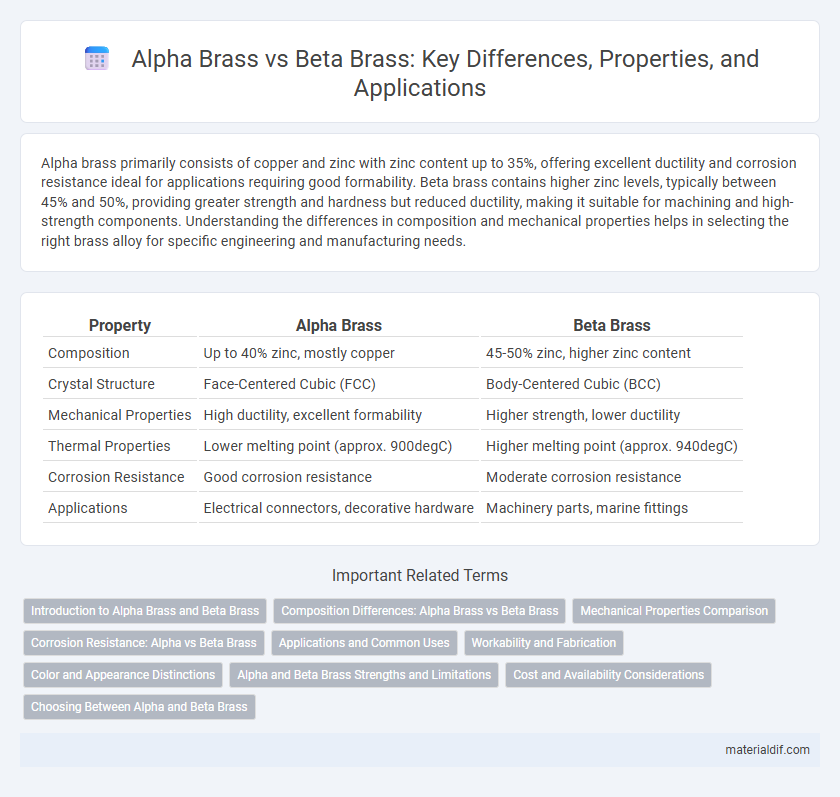

Table of Comparison

| Property | Alpha Brass | Beta Brass |

|---|---|---|

| Composition | Up to 40% zinc, mostly copper | 45-50% zinc, higher zinc content |

| Crystal Structure | Face-Centered Cubic (FCC) | Body-Centered Cubic (BCC) |

| Mechanical Properties | High ductility, excellent formability | Higher strength, lower ductility |

| Thermal Properties | Lower melting point (approx. 900degC) | Higher melting point (approx. 940degC) |

| Corrosion Resistance | Good corrosion resistance | Moderate corrosion resistance |

| Applications | Electrical connectors, decorative hardware | Machinery parts, marine fittings |

Introduction to Alpha Brass and Beta Brass

Alpha brass primarily consists of copper and zinc with a zinc content below 40%, characterized by its single-phase face-centered cubic (FCC) crystal structure that provides excellent ductility and cold-working properties. Beta brass contains higher zinc levels, typically between 40% and 50%, and exhibits a body-centered cubic (BCC) structure in its beta phase, resulting in increased strength and hardness but reduced malleability compared to alpha brass. These microstructural differences influence the suitability of alpha brass for applications requiring extensive forming and beta brass for components demanding greater mechanical strength.

Composition Differences: Alpha Brass vs Beta Brass

Alpha brass primarily contains 60-70% copper and 30-40% zinc, maintaining a single-phase alpha microstructure that provides excellent ductility and corrosion resistance. Beta brass, on the other hand, features a higher zinc content, typically between 40-50%, resulting in a two-phase microstructure composed of both alpha and beta phases, which enhances strength and hardness but reduces malleability. These compositional differences directly influence their mechanical properties and suitability for various industrial applications.

Mechanical Properties Comparison

Alpha brass, composed primarily of copper and less than 35% zinc, exhibits higher tensile strength and excellent ductility, making it suitable for cold working and applications requiring formability. Beta brass contains a higher zinc content, typically between 35% and 45%, resulting in increased hardness and strength but reduced ductility, ideal for hot working and wear-resistant uses. The mechanical properties of alpha brass favor flexibility and corrosion resistance, while beta brass offers superior strength and machinability under elevated temperatures.

Corrosion Resistance: Alpha vs Beta Brass

Alpha brass, primarily composed of copper and less than 35% zinc, exhibits superior corrosion resistance due to its single-phase alpha structure, which reduces galvanic interaction and maintains integrity in marine and industrial environments. Beta brass, containing higher zinc content (above 45%) with a mixed alpha-beta phase, tends to be less corrosion-resistant as the beta phase is more anodic, making it more susceptible to dezincification and stress corrosion cracking. Therefore, alpha brass is preferred for applications demanding long-term durability and resistance to harsh corrosive conditions.

Applications and Common Uses

Alpha brass, composed primarily of copper and less than 35% zinc, is widely used in applications requiring good cold working properties and corrosion resistance, such as plumbing fittings, musical instruments, and decorative hardware. Beta brass contains higher zinc content (above 45%) and often includes lead or other additives, making it suitable for high-strength applications like gears, marine hardware, and valve components where strength and wear resistance are critical. Both alpha and beta brass alloys are essential in manufacturing, but their distinct compositions tailor them to different industrial uses based on mechanical properties and environmental resistance.

Workability and Fabrication

Alpha brass, composed primarily of copper and less than 35% zinc, exhibits excellent workability and is ideal for intricate fabrication processes such as drawing, spinning, and deep drawing due to its single-phase microstructure. Beta brass contains higher zinc content, typically between 35% to 45%, offering increased strength but reduced ductility, making it more suitable for machining and hot working rather than cold fabrication. The choice between alpha and beta brass depends on the required balance between ease of forming and mechanical strength in the final product.

Color and Appearance Distinctions

Alpha brass, composed primarily of copper and zinc with zinc content up to 35%, exhibits a bright, yellow-gold color with excellent malleability and a smooth, shiny surface ideal for decorative applications. Beta brass contains a higher zinc content, typically between 45% and 50%, resulting in a paler, more silvery appearance with increased hardness but reduced ductility, often used in industrial components and machining. The distinct color differentiation--alpha brass's vibrant yellow versus beta brass's muted tone--reflects their microstructural differences and functional uses in manufacturing.

Alpha and Beta Brass Strengths and Limitations

Alpha brass, consisting primarily of copper and less than 35% zinc, exhibits excellent ductility, corrosion resistance, and acoustic properties, making it ideal for applications requiring formability and high thermal conductivity. Beta brass contains a higher zinc content, typically between 35% and 45%, resulting in increased strength and hardness but with reduced ductility and poorer corrosion resistance compared to alpha brass. The trade-off between alpha and beta brass lies in alpha's superior machinability and resilience versus beta's enhanced mechanical strength suited for heavy-duty applications.

Cost and Availability Considerations

Alpha brass, primarily composed of copper and zinc with less than 35% zinc, tends to be more cost-effective and widely available due to its simpler alloy composition and extensive industrial use. Beta brass, containing higher zinc content (above 45%) and often requiring heat treatment, typically incurs higher production costs and is less readily available because of its specialized applications and manufacturing complexity. Manufacturers often choose alpha brass for budget-sensitive, high-volume projects while reserving beta brass for high-strength or wear-resistant components despite its premium cost and limited supply.

Choosing Between Alpha and Beta Brass

Choosing between alpha brass and beta brass depends on the required mechanical properties and corrosion resistance for the application. Alpha brass, containing less than 35% zinc, offers excellent cold workability and superior corrosion resistance, making it ideal for plumbing and decorative purposes. Beta brass, with higher zinc content above 45%, provides increased strength and hardness after heat treatment, suitable for heavy-duty industrial components.

Alpha Brass vs Beta Brass Infographic

materialdif.com

materialdif.com