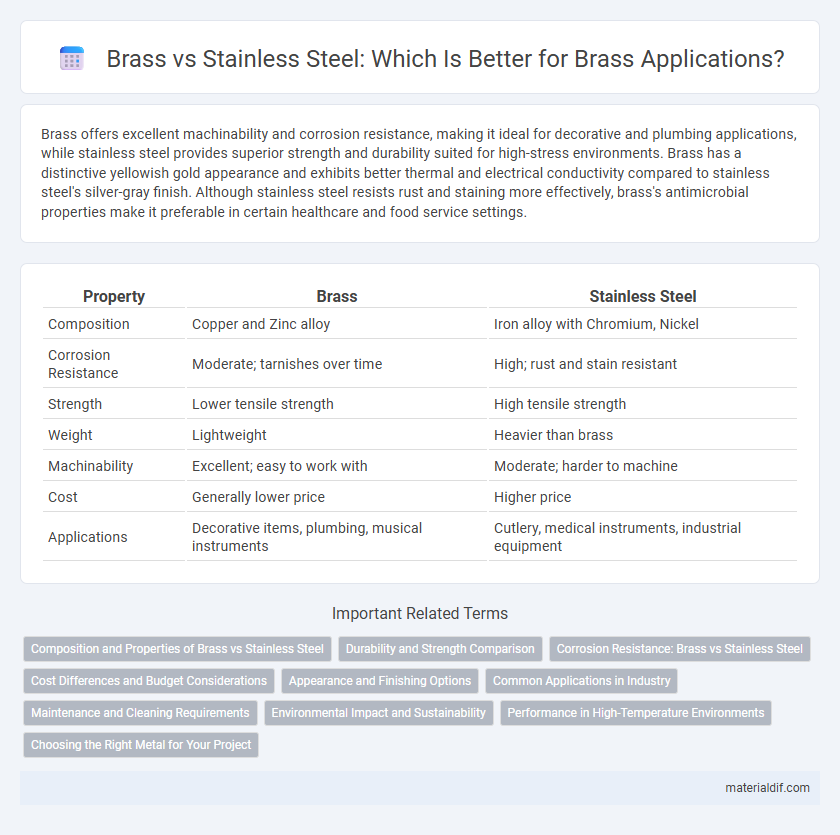

Brass offers excellent machinability and corrosion resistance, making it ideal for decorative and plumbing applications, while stainless steel provides superior strength and durability suited for high-stress environments. Brass has a distinctive yellowish gold appearance and exhibits better thermal and electrical conductivity compared to stainless steel's silver-gray finish. Although stainless steel resists rust and staining more effectively, brass's antimicrobial properties make it preferable in certain healthcare and food service settings.

Table of Comparison

| Property | Brass | Stainless Steel |

|---|---|---|

| Composition | Copper and Zinc alloy | Iron alloy with Chromium, Nickel |

| Corrosion Resistance | Moderate; tarnishes over time | High; rust and stain resistant |

| Strength | Lower tensile strength | High tensile strength |

| Weight | Lightweight | Heavier than brass |

| Machinability | Excellent; easy to work with | Moderate; harder to machine |

| Cost | Generally lower price | Higher price |

| Applications | Decorative items, plumbing, musical instruments | Cutlery, medical instruments, industrial equipment |

Composition and Properties of Brass vs Stainless Steel

Brass is an alloy primarily composed of copper and zinc, offering excellent corrosion resistance, high malleability, and superior thermal and electrical conductivity compared to stainless steel, which is mainly composed of iron, chromium, and nickel. Stainless steel provides greater tensile strength, higher resistance to oxidation, and enhanced durability under extreme temperatures, making it ideal for structural and high-stress applications. Brass's antimicrobial properties and ease of machining contrast with stainless steel's hardness and resistance to staining, defining their distinct industrial uses and performance characteristics.

Durability and Strength Comparison

Brass, an alloy of copper and zinc, offers moderate durability and strength with excellent corrosion resistance, making it ideal for decorative and low-stress applications. Stainless steel, composed mainly of iron, carbon, and chromium, exceeds brass in tensile strength and hardness, providing superior durability for heavy-duty and structural uses. While brass resists wear and tarnishing, stainless steel is better suited for environments requiring enhanced mechanical resilience and prolonged lifespan.

Corrosion Resistance: Brass vs Stainless Steel

Brass offers moderate corrosion resistance, particularly effective against water and non-aggressive environments, but it tends to tarnish and develop patina over time. Stainless steel provides superior corrosion resistance due to its chromium content, forming a passive oxide layer that prevents rust and withstands harsh chemicals and marine conditions. In applications requiring long-term durability in corrosive environments, stainless steel typically outperforms brass.

Cost Differences and Budget Considerations

Brass typically costs more than stainless steel due to its higher copper content and alloy complexity, impacting initial project budgets. Stainless steel offers a more affordable option with excellent corrosion resistance, making it suitable for cost-sensitive applications. Selecting between brass and stainless steel requires evaluating long-term maintenance expenses alongside upfront material costs to optimize budget allocation.

Appearance and Finishing Options

Brass offers a warm, golden hue that develops a natural patina over time, enhancing its vintage appeal, while stainless steel provides a sleek, modern silver-gray finish with high resistance to tarnishing and corrosion. Brass supports a variety of finishing options such as polishing, lacquering, antiquing, and brushing, allowing for both glossy and matte aesthetics. Stainless steel commonly features finishes like brushed, satin, mirror polish, or bead blasting, delivering durable surfaces suited for contemporary design and high-traffic applications.

Common Applications in Industry

Brass is widely used in plumbing, electrical connectors, and musical instruments due to its excellent machinability, corrosion resistance, and thermal conductivity. Stainless steel is preferred in food processing, medical instruments, and chemical industries for its superior strength, corrosion resistance, and hygienic properties. Both metals serve critical roles in manufacturing, with brass favored for aesthetic and conductive applications, while stainless steel dominates high-strength and sterile environments.

Maintenance and Cleaning Requirements

Brass requires regular polishing to prevent tarnishing and maintain its shine, as exposure to air and moisture causes oxidation. Stainless steel offers superior resistance to corrosion and staining, allowing for easier cleaning with mild detergents and minimal upkeep. Both materials benefit from routine cleaning, but stainless steel demands less intensive maintenance compared to brass.

Environmental Impact and Sustainability

Brass, composed primarily of copper and zinc, offers superior recyclability compared to stainless steel, reducing waste and environmental burden. The production of brass generally consumes less energy than stainless steel, resulting in lower carbon emissions during manufacturing. Brass's durability and corrosion resistance extend product lifespan, promoting sustainability by minimizing the need for frequent replacements.

Performance in High-Temperature Environments

Brass exhibits good thermal conductivity and moderate strength, but its performance declines at temperatures above 200degC due to oxidation and reduced mechanical stability. Stainless steel maintains superior strength and corrosion resistance at high temperatures, often withstanding conditions exceeding 800degC without significant degradation. For applications requiring durability in extreme heat, stainless steel outperforms brass by retaining structural integrity and resisting scaling.

Choosing the Right Metal for Your Project

Brass offers excellent corrosion resistance, electrical conductivity, and a distinct golden appearance, making it ideal for decorative and marine applications. Stainless steel provides superior strength, durability, and resistance to rust and staining, suited for structural and high-stress environments. Selecting the right metal depends on factors like environmental exposure, mechanical requirements, and aesthetic preferences.

Brass vs Stainless Steel Infographic

materialdif.com

materialdif.com