Alpha brass consists primarily of copper and zinc, typically with a zinc content below 35%, offering excellent corrosion resistance and good cold working properties. Alpha-beta brass contains a higher zinc percentage, usually between 35% and 45%, providing greater strength and hardness but reduced ductility compared to alpha brass. Choosing between alpha and alpha-beta brass depends on the required balance of machinability, strength, and corrosion resistance for specific applications.

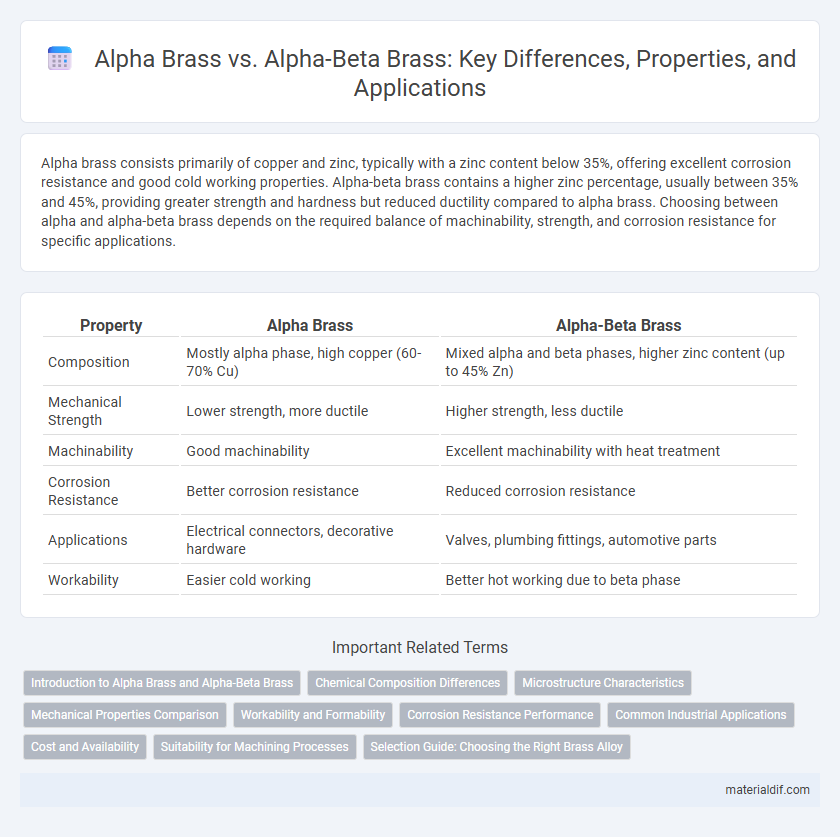

Table of Comparison

| Property | Alpha Brass | Alpha-Beta Brass |

|---|---|---|

| Composition | Mostly alpha phase, high copper (60-70% Cu) | Mixed alpha and beta phases, higher zinc content (up to 45% Zn) |

| Mechanical Strength | Lower strength, more ductile | Higher strength, less ductile |

| Machinability | Good machinability | Excellent machinability with heat treatment |

| Corrosion Resistance | Better corrosion resistance | Reduced corrosion resistance |

| Applications | Electrical connectors, decorative hardware | Valves, plumbing fittings, automotive parts |

| Workability | Easier cold working | Better hot working due to beta phase |

Introduction to Alpha Brass and Alpha-Beta Brass

Alpha Brass primarily consists of a copper-zinc alloy with zinc content typically ranging between 35% and 45%, resulting in a single-phase microstructure known as the alpha phase, which offers excellent corrosion resistance, high ductility, and good strength. Alpha-Beta Brass contains a higher zinc percentage, usually between 45% and 50%, featuring a dual-phase microstructure composed of both alpha and beta phases, enhancing machinability and strength but reducing ductility. These differences make Alpha Brass ideal for deep drawing and forming applications, while Alpha-Beta Brass is preferred in heavy machining and structural components.

Chemical Composition Differences

Alpha brass primarily consists of copper with zinc content ranging from 5% to 35%, resulting in a single-phase solid solution known for excellent cold working and corrosion resistance. Alpha-beta brass, also referred to as duplex brass, contains a higher zinc concentration between 35% and 45%, featuring a two-phase microstructure of alpha and beta phases that enhances strength and machinability. The chemical composition difference significantly affects mechanical properties, with alpha brasses used for deep drawing applications, while alpha-beta brasses are preferred for forging and hot working due to their increased hardness.

Microstructure Characteristics

Alpha brass microstructure consists primarily of a single face-centered cubic (FCC) alpha phase, offering excellent ductility and corrosion resistance due to its uniform grain structure. In contrast, Alpha-Beta brass exhibits a dual-phase microstructure combining the alpha phase with a body-centered cubic (BCC) beta phase, enhancing strength and hardness but reducing ductility. The presence of the beta phase in Alpha-Beta brass creates a more complex microstructure, resulting in improved mechanical properties suitable for high-stress applications.

Mechanical Properties Comparison

Alpha brass, composed primarily of copper and up to 35% zinc, exhibits superior ductility and excellent cold working capabilities due to its single-phase microstructure. In contrast, alpha-beta brass contains both alpha (FCC) and beta (BCC) phases, providing higher strength and hardness but reduced ductility and machinability. Therefore, alpha brass is preferred for applications requiring extensive forming, while alpha-beta brass suits environments demanding greater mechanical strength.

Workability and Formability

Alpha brass, composed primarily of copper and zinc with less than 35% zinc, offers superior workability due to its single-phase structure that allows for extensive cold working and easy forming processes such as bending and drawing. Alpha-beta brass contains higher zinc content, typically between 35% and 45%, leading to a dual-phase microstructure that improves strength but reduces formability and increases susceptibility to cracking during cold working. Manufacturers often prefer alpha brass for applications requiring high ductility and ease of intricate shaping, while alpha-beta brass suits components needing greater mechanical strength with moderate forming capabilities.

Corrosion Resistance Performance

Alpha brass, composed primarily of copper and zinc with zinc content below 35%, exhibits superior corrosion resistance due to its single-phase microstructure, making it ideal for marine and chemical applications. In contrast, alpha-beta brass contains a dual-phase microstructure with higher zinc content, which enhances mechanical strength but reduces corrosion resistance, especially in acidic or chlorinated environments. The alpha phase's uniform grain structure imparts better resistance to dezincification and stress corrosion cracking compared to the mixed phases in alpha-beta brass.

Common Industrial Applications

Alpha brass, composed mostly of copper and zinc with less than 35% zinc, is preferred for applications requiring high ductility and corrosion resistance, such as electrical connectors, plumbing fittings, and musical instruments. Alpha-beta brass, containing between 35% to 45% zinc, offers improved strength and machinability, making it ideal for industrial uses like gears, valves, and heavy-duty fasteners in automotive and marine equipment. Both types leverage their unique mechanical properties to enhance performance in specific manufacturing sectors.

Cost and Availability

Alpha brass, typically composed of 60-70% copper and zinc, offers better machinability and is generally less expensive due to simpler production processes and widespread availability. Alpha-beta brass, containing more zinc (up to 45%) and including beta phase grains, tends to be stronger and harder but incurs higher costs linked to complex manufacturing and more limited supply. Cost-efficiency and availability often make alpha brass the preferred choice for applications requiring ease of machining and moderate strength.

Suitability for Machining Processes

Alpha brass, composed mainly of copper and zinc with zinc content below 35%, offers excellent machinability due to its single-phase microstructure, making it ideal for precision components and intricate machining processes. Alpha-beta brass, containing higher zinc content between 35% and 45%, features a dual-phase microstructure that enhances strength but reduces machinability, requiring more robust tooling and slower cutting speeds during manufacturing. The choice between alpha and alpha-beta brass depends on the balance needed between ease of machining and mechanical strength for specific industrial applications.

Selection Guide: Choosing the Right Brass Alloy

Alpha brass, typically composed of copper with up to 45% zinc, offers excellent cold working properties and corrosion resistance, making it ideal for applications requiring high ductility and formability. Alpha-beta brass, containing between 45% and 50% zinc, combines both alpha and beta phases, providing higher strength and machinability but reduced corrosion resistance. Selecting the right brass alloy depends on balancing mechanical strength, corrosion resistance, and machinability requirements specific to the intended application.

Alpha Brass vs Alpha-Beta Brass Infographic

materialdif.com

materialdif.com