High-tensile brass offers superior strength and durability, making it ideal for applications requiring resistance to wear and mechanical stress. Low-tensile brass, while easier to machine and form, may lack the structural integrity needed for high-stress environments. Selecting between high-tensile and low-tensile brass depends on balancing mechanical demands with manufacturing processes.

Table of Comparison

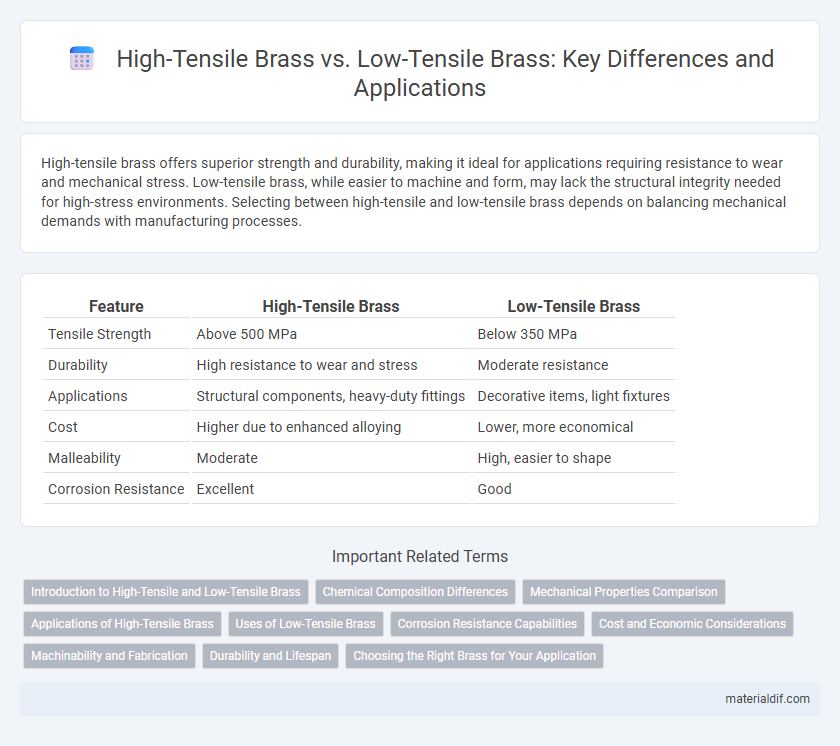

| Feature | High-Tensile Brass | Low-Tensile Brass |

|---|---|---|

| Tensile Strength | Above 500 MPa | Below 350 MPa |

| Durability | High resistance to wear and stress | Moderate resistance |

| Applications | Structural components, heavy-duty fittings | Decorative items, light fixtures |

| Cost | Higher due to enhanced alloying | Lower, more economical |

| Malleability | Moderate | High, easier to shape |

| Corrosion Resistance | Excellent | Good |

Introduction to High-Tensile and Low-Tensile Brass

High-tensile brass exhibits superior mechanical strength and resistance to deformation compared to low-tensile brass, making it ideal for applications requiring durability and load-bearing capacity. Low-tensile brass offers greater ductility and ease of machining, suitable for decorative and less structurally demanding uses. The difference in tensile strength between these types is primarily due to variations in alloy composition and processing techniques.

Chemical Composition Differences

High-tensile brass typically contains higher concentrations of zinc, ranging from 30% to 40%, which enhances its strength and hardness compared to low-tensile brass that usually has zinc content below 30%. Low-tensile brass often contains increased amounts of lead and tin to improve machinability and corrosion resistance but at the expense of mechanical strength. The difference in chemical composition, particularly zinc and alloying elements, directly influences the mechanical properties and suitability of each brass type for specific industrial applications.

Mechanical Properties Comparison

High-tensile brass exhibits superior mechanical properties compared to low-tensile brass, including higher tensile strength, enhanced hardness, and improved wear resistance, making it ideal for demanding applications. Low-tensile brass typically offers greater ductility and ease of machining but with reduced load-bearing capacity and lower yield strength. The choice between these alloys depends on the specific mechanical requirements, balancing strength and formability for optimal performance in industrial components.

Applications of High-Tensile Brass

High-tensile brass, known for its superior strength and durability, is widely used in applications requiring enhanced mechanical performance, such as automotive components, heavy-duty fasteners, and high-pressure valve systems. Its resistance to wear and fatigue makes it ideal for manufacturing gears, shafts, and springs exposed to rigorous operational stress. Compared to low-tensile brass, high-tensile variants significantly improve longevity and reliability in industrial and engineering environments.

Uses of Low-Tensile Brass

Low-tensile brass, characterized by its lower mechanical strength and higher malleability, is widely used in applications requiring easy formability and corrosion resistance, such as decorative fixtures, musical instruments, and plumbing components. Its enhanced ductility allows for intricate shaping and machining, making it ideal for precision parts in automotive and electrical industries. The alloy's resistance to tarnish and corrosion ensures durability in environments exposed to moisture and chemicals.

Corrosion Resistance Capabilities

High-tensile brass exhibits superior corrosion resistance due to its denser microstructure and alloy composition, making it ideal for marine and industrial applications exposed to harsh environments. Low-tensile brass, while more malleable and easier to shape, tends to have lower resistance to corrosion, which can lead to quicker material degradation when exposed to moisture and chemicals. Selecting high-tensile brass enhances long-term durability and reliability in corrosive settings, reducing maintenance and replacement costs.

Cost and Economic Considerations

High-tensile brass offers superior strength and durability, making it ideal for demanding applications, but its production cost is significantly higher due to alloy composition and processing complexity. Low-tensile brass is more cost-effective for projects with less mechanical stress, providing adequate performance at a lower price point. Choosing between high-tensile and low-tensile brass depends on balancing budget constraints with performance requirements to optimize overall economic efficiency.

Machinability and Fabrication

High-tensile brass offers superior machinability due to its enhanced strength and hardness, enabling precise cutting and shaping with minimal tool wear. Low-tensile brass, characterized by greater ductility, allows easier fabrication processes such as bending and forming, but it may require slower machining speeds to avoid material deformation. Selecting between these alloys depends on balancing the need for machinability efficiency against fabrication flexibility in specific industrial applications.

Durability and Lifespan

High-tensile brass exhibits superior durability due to its enhanced tensile strength, making it highly resistant to wear and deformation under stress. This alloy's extended lifespan outperforms low-tensile brass, which tends to deform or fail more quickly under heavy loads or repeated mechanical strain. Applications demanding long-term reliability, such as marine fittings and mechanical components, benefit significantly from the robustness of high-tensile brass.

Choosing the Right Brass for Your Application

High-tensile brass offers superior strength and durability, making it ideal for applications subjected to high mechanical stress or load-bearing conditions. Low-tensile brass provides better malleability and corrosion resistance, suited for decorative or low-stress environments where ease of fabrication is critical. Selecting the appropriate brass grade depends on balancing mechanical requirements with environmental factors to ensure optimal performance and longevity.

High-Tensile Brass vs Low-Tensile Brass Infographic

materialdif.com

materialdif.com