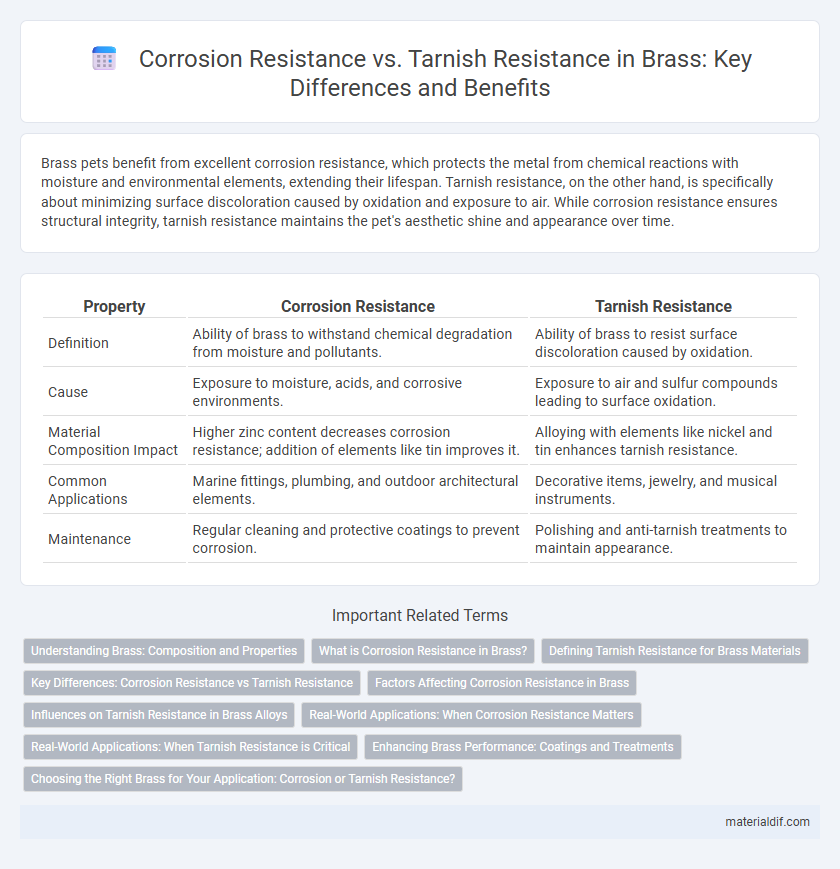

Brass pets benefit from excellent corrosion resistance, which protects the metal from chemical reactions with moisture and environmental elements, extending their lifespan. Tarnish resistance, on the other hand, is specifically about minimizing surface discoloration caused by oxidation and exposure to air. While corrosion resistance ensures structural integrity, tarnish resistance maintains the pet's aesthetic shine and appearance over time.

Table of Comparison

| Property | Corrosion Resistance | Tarnish Resistance |

|---|---|---|

| Definition | Ability of brass to withstand chemical degradation from moisture and pollutants. | Ability of brass to resist surface discoloration caused by oxidation. |

| Cause | Exposure to moisture, acids, and corrosive environments. | Exposure to air and sulfur compounds leading to surface oxidation. |

| Material Composition Impact | Higher zinc content decreases corrosion resistance; addition of elements like tin improves it. | Alloying with elements like nickel and tin enhances tarnish resistance. |

| Common Applications | Marine fittings, plumbing, and outdoor architectural elements. | Decorative items, jewelry, and musical instruments. |

| Maintenance | Regular cleaning and protective coatings to prevent corrosion. | Polishing and anti-tarnish treatments to maintain appearance. |

Understanding Brass: Composition and Properties

Brass, an alloy primarily composed of copper and zinc, exhibits notable corrosion resistance due to the protective oxide layer formed on its surface. Tarnish resistance in brass varies with the zinc content and presence of other elements like tin or aluminum, which enhance surface stability against oxidation. Understanding the specific composition and microstructure of brass is essential to optimizing its performance in applications requiring durability and aesthetic longevity.

What is Corrosion Resistance in Brass?

Corrosion resistance in brass refers to its ability to withstand degradation caused by environmental factors such as moisture, chemicals, and air exposure, preventing the metal from rusting or deteriorating over time. This property is primarily due to the presence of zinc and other alloying elements that enhance brass's durability in various industrial and marine applications. Understanding corrosion resistance is essential for selecting brass alloys in plumbing, automotive parts, and electrical components where longevity and reliability are critical.

Defining Tarnish Resistance for Brass Materials

Tarnish resistance in brass materials refers to the alloy's ability to resist surface discoloration caused by oxidation and exposure to environmental elements such as sulfur and moisture. Unlike corrosion resistance, which involves preventing material degradation and structural damage, tarnish resistance primarily affects the aesthetic appearance by maintaining a bright, shiny surface. Enhanced tarnish resistance in brass is achieved through specific alloying elements like zinc and tin, which form protective oxide layers that inhibit surface darkening.

Key Differences: Corrosion Resistance vs Tarnish Resistance

Brass exhibits corrosion resistance by maintaining structural integrity against chemical or electrochemical reactions with moisture, acids, or salts, whereas tarnish resistance specifically refers to the ability to prevent surface discoloration caused by oxidation or sulfide exposure. Corrosion resistance impacts the lifespan and mechanical performance of brass, while tarnish resistance primarily affects its aesthetic appearance and surface finish. Understanding these differences is crucial when selecting brass for applications requiring either durability in harsh environments or sustained visual appeal.

Factors Affecting Corrosion Resistance in Brass

Corrosion resistance in brass is primarily influenced by its alloy composition, with higher copper content typically enhancing resistance to oxidation and acidic environments. Environmental factors such as moisture, exposure to chlorides, and temperature fluctuations also critically affect the integrity of brass surfaces. Protective coatings and surface treatments can further improve corrosion resistance, minimizing the onset of tarnish and prolonging the material's functional lifespan.

Influences on Tarnish Resistance in Brass Alloys

Tarnish resistance in brass alloys is primarily influenced by the alloy's composition, particularly the zinc and copper content, with higher copper percentages generally enhancing tarnish resistance. Surface treatments such as plating or lacquering can significantly reduce exposure to air and moisture, thereby improving resistance to tarnishing. Environmental factors like humidity, temperature, and exposure to sulfur-containing compounds also play crucial roles in accelerating or mitigating tarnish formation on brass surfaces.

Real-World Applications: When Corrosion Resistance Matters

Brass alloys with high copper and zinc content exhibit excellent corrosion resistance, making them ideal for plumbing fixtures, marine hardware, and industrial valves exposed to moisture and chemicals. Tarnish resistance, while important for aesthetic longevity in decorative items and musical instruments, does not prevent the material degradation that can compromise mechanical integrity in harsh environments. In real-world applications like chemical processing or outdoor installations, corrosion resistance is critical to ensure durability, safety, and maintenance cost reduction.

Real-World Applications: When Tarnish Resistance is Critical

Brass alloys with high copper and zinc content exhibit excellent corrosion resistance, making them suitable for plumbing and marine environments where exposure to moisture and chemicals is frequent. Tarnish resistance becomes critical in decorative applications such as musical instruments, jewelry, and architectural hardware where aesthetic appeal must be maintained without frequent polishing. Understanding the balance between corrosion and tarnish resistance helps manufacturers select the right brass formulation for both durability and long-lasting visual quality.

Enhancing Brass Performance: Coatings and Treatments

Enhancing brass performance involves applying coatings such as clear lacquers, epoxy resins, or specialized corrosion inhibitors that significantly improve corrosion resistance by forming a protective barrier against moisture and environmental contaminants. Tarnish resistance can be boosted through surface treatments like passivation, which alters the brass surface chemistry to reduce oxidation, and plating with materials like nickel or chrome that offer both aesthetic and protective benefits. Combining these coatings and treatments ensures long-lasting durability and maintains the metal's visual appeal in various applications, from architectural fixtures to musical instruments.

Choosing the Right Brass for Your Application: Corrosion or Tarnish Resistance?

Brass alloys with higher copper content, such as C260 (cartridge brass), exhibit superior corrosion resistance, making them ideal for marine and plumbing applications where moisture exposure is frequent. For decorative purposes where appearance matters more, brass grades like C270 (yellow brass) offer enhanced tarnish resistance due to their zinc-rich composition, which helps maintain a bright finish over time. Selecting the appropriate brass depends on balancing environmental exposure and aesthetic requirements to ensure longevity and performance in your specific application.

Corrosion Resistance vs Tarnish Resistance Infographic

materialdif.com

materialdif.com