Cartridge brass, typically composed of 70% copper and 30% zinc, offers excellent ductility and strength, making it ideal for ammunition casings and various industrial applications. Admiralty brass contains a small amount of tin in addition to copper and zinc, enhancing its corrosion resistance and suitability for marine environments. The performance difference lies in cartridge brass's higher malleability versus Admiralty brass's superior resistance to seawater and stress corrosion cracking.

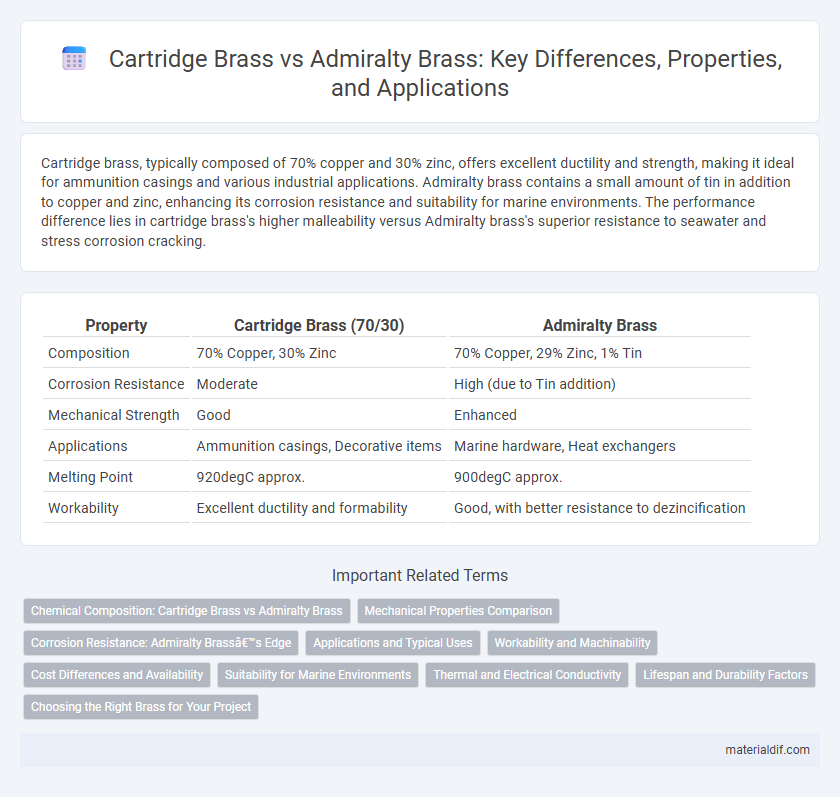

Table of Comparison

| Property | Cartridge Brass (70/30) | Admiralty Brass |

|---|---|---|

| Composition | 70% Copper, 30% Zinc | 70% Copper, 29% Zinc, 1% Tin |

| Corrosion Resistance | Moderate | High (due to Tin addition) |

| Mechanical Strength | Good | Enhanced |

| Applications | Ammunition casings, Decorative items | Marine hardware, Heat exchangers |

| Melting Point | 920degC approx. | 900degC approx. |

| Workability | Excellent ductility and formability | Good, with better resistance to dezincification |

Chemical Composition: Cartridge Brass vs Admiralty Brass

Cartridge Brass typically contains 70% copper and 30% zinc, providing excellent ductility and corrosion resistance suited for ammunition casings. Admiralty Brass consists of approximately 70% copper, 29% zinc, and 1% tin, enhancing its strength and seawater corrosion resistance, making it ideal for maritime applications. The addition of tin in Admiralty Brass differentiates its chemical composition, improving mechanical properties compared to the simpler Copper-Zinc ratio in Cartridge Brass.

Mechanical Properties Comparison

Cartridge brass (70% copper, 30% zinc) exhibits high tensile strength around 440 MPa and excellent ductility, making it ideal for ammunition casings requiring reliable deformation under stress. Admiralty brass (70% copper, 29% zinc, 1% tin) offers enhanced corrosion resistance and slightly lower tensile strength near 400 MPa, with improved hardness and better performance in marine environments. Mechanical properties such as yield strength, elongation, and hardness show cartridge brass excels in formability while Admiralty brass balances strength with superior corrosion resistance for durability in harsh conditions.

Corrosion Resistance: Admiralty Brass’s Edge

Admiralty Brass exhibits superior corrosion resistance compared to Cartridge Brass due to its higher copper content and the inclusion of tin, which enhances its ability to withstand seawater and acidic environments. This alloy's resilience makes it ideal for marine applications where exposure to harsh conditions is frequent. Cartridge Brass, with a higher zinc concentration, is more prone to dezincification and corrosion in such environments, limiting its use in aggressive settings.

Applications and Typical Uses

Cartridge brass (typically 70% copper and 30% zinc) is widely used in ammunition casings, electrical connectors, and decorative applications due to its excellent ductility, corrosion resistance, and ease of fabrication. Admiralty brass (around 70% copper, 29% zinc, and 1% tin) finds common use in marine environments, such as ship propellers, condenser tubes, and seawater fittings, because of its enhanced resistance to dezincification and superior strength in corrosive seawater conditions. The distinct alloy compositions of these brasses determine their suitability for specific industrial and environmental demands.

Workability and Machinability

Cartridge Brass, typically composed of 70% copper and 30% zinc, exhibits excellent workability due to its fine grain structure, allowing it to be easily formed and drawn into various shapes without cracking. Admiralty Brass, containing about 70% copper, 29% zinc, and 1% tin, offers superior machinability because the tin improves grain stability and reduces dezincification, making it ideal for precision machining applications. Both alloys are favored in manufacturing, but Cartridge Brass excels in cold working processes, while Admiralty Brass is preferred for components requiring high corrosion resistance and mechanical strength during machining.

Cost Differences and Availability

Cartridge brass, typically composed of 70% copper and 30% zinc, offers widespread availability and lower cost due to its common use in ammunition and mass-produced components. Admiralty brass, containing around 70% copper, 29% zinc, and 1% tin, commands higher prices because of its enhanced corrosion resistance and limited production for marine applications. Cost differences stem from raw material composition and manufacturing scale, making cartridge brass more economical and easier to source than the specialized Admiralty brass.

Suitability for Marine Environments

Cartridge Brass, composed primarily of 70% copper and 30% zinc, offers excellent corrosion resistance but is less suited for prolonged exposure to harsh marine environments due to its susceptibility to dezincification. Admiralty Brass, an alloy containing approximately 70% copper, 29% zinc, and 1% tin, demonstrates superior resistance to seawater corrosion and dezincification, making it more suitable for marine applications such as ship fittings and seawater piping. The presence of tin in Admiralty Brass significantly enhances its durability and service life in saline conditions compared to standard Cartridge Brass.

Thermal and Electrical Conductivity

Cartridge Brass exhibits higher thermal conductivity around 110 W/m*K and electrical conductivity of approximately 28% IACS, making it ideal for applications requiring efficient heat dissipation and electrical performance. Admiralty Brass, with thermal conductivity near 120 W/m*K and superior electrical conductivity reaching about 30% IACS, offers enhanced performance in marine and industrial environments where corrosion resistance is critical. Both alloys balance conductivity properties with strength, but Admiralty Brass typically outperforms Cartridge Brass in conductivity metrics due to its specific composition including tin.

Lifespan and Durability Factors

Cartridge brass, primarily composed of 70% copper and 30% zinc, offers enhanced corrosion resistance and superior tensile strength, making it ideal for applications requiring long lifespan under mechanical stress. Admiralty brass, containing about 70% copper, 29% zinc, and 1% tin, provides increased resistance to dezincification and seawater corrosion, crucial for marine environments where durability is paramount. The tin addition in Admiralty brass significantly improves its durability by preventing zinc leaching, thereby extending its service life compared to standard cartridge brass in harsh conditions.

Choosing the Right Brass for Your Project

Cartridge brass, primarily composed of 70% copper and 30% zinc, offers excellent ductility and corrosion resistance, making it ideal for ammunition casings and precision engineering projects. Admiralty brass, with a composition of 70% copper, 29% zinc, and 1% tin, provides superior resistance to dezincification and is preferred in marine and hydraulic applications. Selecting the right brass depends on the required mechanical strength, corrosion resistance, and environmental exposure specific to your project needs.

Cartridge Brass vs Admiralty Brass Infographic

materialdif.com

materialdif.com