Annealed brass offers enhanced ductility and improved machinability due to the softening process that relieves internal stresses, making it ideal for complex forming and shaping applications. Cold-worked brass maintains higher strength and hardness from plastic deformation at lower temperatures but sacrifices some malleability and is more prone to stress-related fractures. Selecting between annealed and cold-worked brass depends on the required balance of strength and formability for specific manufacturing needs.

Table of Comparison

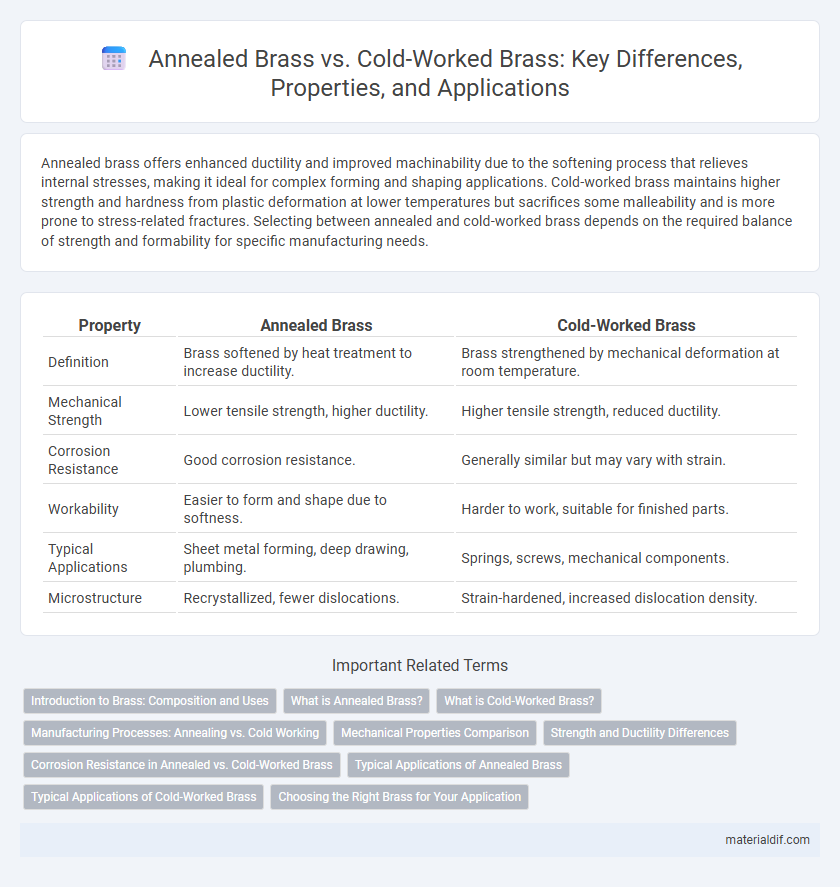

| Property | Annealed Brass | Cold-Worked Brass |

|---|---|---|

| Definition | Brass softened by heat treatment to increase ductility. | Brass strengthened by mechanical deformation at room temperature. |

| Mechanical Strength | Lower tensile strength, higher ductility. | Higher tensile strength, reduced ductility. |

| Corrosion Resistance | Good corrosion resistance. | Generally similar but may vary with strain. |

| Workability | Easier to form and shape due to softness. | Harder to work, suitable for finished parts. |

| Typical Applications | Sheet metal forming, deep drawing, plumbing. | Springs, screws, mechanical components. |

| Microstructure | Recrystallized, fewer dislocations. | Strain-hardened, increased dislocation density. |

Introduction to Brass: Composition and Uses

Annealed brass undergoes a heat treatment process to increase its ductility by relieving internal stresses, making it easier to shape and form for applications such as plumbing fittings and decorative items. Cold-worked brass is mechanically strengthened through deformation processes like rolling or drawing, resulting in higher tensile strength suitable for structural components and precision instruments. Both types consist primarily of copper and zinc, with varying zinc content influencing their machinability, corrosion resistance, and suitability for diverse industrial and architectural applications.

What is Annealed Brass?

Annealed brass is a type of brass alloy that has undergone a heat treatment process to soften the metal, enhancing its ductility and machinability. This thermal treatment relieves internal stresses caused by previous cold working, resulting in a more malleable material ideal for forming, bending, and shaping applications. Annealed brass exhibits improved workability compared to cold-worked brass, which remains harder and stronger due to strain hardening from mechanical deformation.

What is Cold-Worked Brass?

Cold-worked brass is a type of brass alloy that has undergone plastic deformation at room temperature, resulting in increased strength and hardness due to strain hardening. This process enhances mechanical properties without altering the alloy's chemical composition, making cold-worked brass ideal for applications requiring high durability and improved wear resistance. Compared to annealed brass, cold-worked brass exhibits less ductility but superior tensile strength and surface finish.

Manufacturing Processes: Annealing vs. Cold Working

Annealed brass undergoes a heat treatment process that softens the metal by relieving internal stresses and increasing ductility, making it easier to shape and form. Cold-worked brass is produced by mechanically deforming the metal at room temperature, which increases its hardness and strength through strain hardening but reduces its malleability. The choice between annealing and cold working significantly impacts the brass's physical properties, influencing its suitability for applications requiring flexibility or durability.

Mechanical Properties Comparison

Annealed brass exhibits lower tensile strength, typically around 250-350 MPa, and higher ductility, allowing it to deform easily without cracking. Cold-worked brass, with tensile strength often exceeding 450 MPa, shows increased hardness and reduced elongation due to strain hardening during deformation. The mechanical property differences make annealed brass suitable for applications requiring formability, while cold-worked brass is preferred for structural components needing enhanced strength.

Strength and Ductility Differences

Annealed brass exhibits lower strength but higher ductility due to the heat treatment process that softens the metal, allowing it to deform more easily without breaking. Cold-worked brass, in contrast, has increased strength and hardness caused by strain hardening from mechanical deformation, though this reduces its ductility. The choice between annealed and cold-worked brass depends on the required balance between durability and formability in applications such as machining or structural components.

Corrosion Resistance in Annealed vs. Cold-Worked Brass

Annealed brass exhibits superior corrosion resistance compared to cold-worked brass due to its reduced internal stress and more uniform microstructure. Cold-worked brass, with higher residual stress and work hardening, is more susceptible to stress corrosion cracking and surface pitting. The annealing process restores ductility and enhances the brass's ability to resist corrosive environments, particularly in marine and industrial applications.

Typical Applications of Annealed Brass

Annealed brass is commonly used in applications requiring high malleability and ease of machining, such as in plumbing fittings, electrical components, and decorative hardware. Its softened state allows for intricate shaping without cracking, making it ideal for manufacturing valves, connectors, and precision instruments. The improved ductility also supports processes like deep drawing and stamping, commonly seen in automotive and musical instrument parts.

Typical Applications of Cold-Worked Brass

Cold-worked brass is commonly used in applications requiring enhanced strength and durability, such as electrical connectors, musical instruments, and fasteners. Its superior hardness and tensile strength compared to annealed brass make it ideal for precision components in the automotive and aerospace industries. The material's resistance to wear and fatigue extends its usefulness in springs and valves subjected to repetitive stress.

Choosing the Right Brass for Your Application

Annealed brass offers enhanced ductility and improved machinability, making it ideal for applications requiring extensive forming or bending without risk of cracking. Cold-worked brass provides greater tensile strength and hardness, suited for structural components where durability and wear resistance are critical. Selecting the right brass depends on balancing mechanical properties with the specific demands of your application, such as flexibility versus strength.

Annealed Brass vs Cold-Worked Brass Infographic

materialdif.com

materialdif.com