Flexible brass offers superior adaptability for applications requiring bending and shaping without compromising strength, making it ideal for intricate plumbing and decorative projects. Rigid brass provides enhanced durability and structural integrity, suited for load-bearing uses and fixed installations where stability is essential. Choosing between flexible and rigid brass depends on the specific requirements of flexibility versus strength in your project.

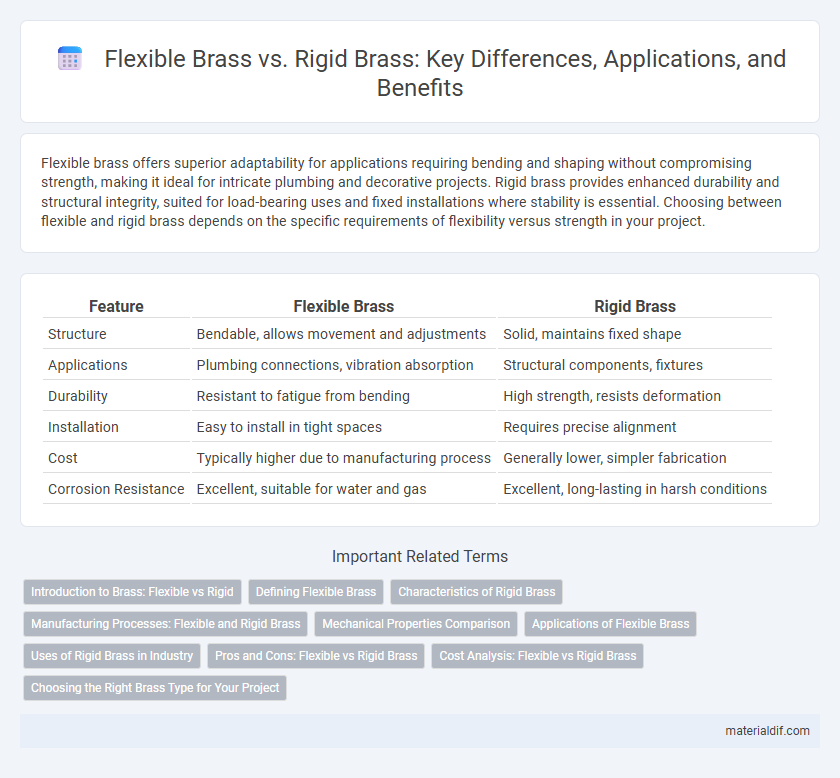

Table of Comparison

| Feature | Flexible Brass | Rigid Brass |

|---|---|---|

| Structure | Bendable, allows movement and adjustments | Solid, maintains fixed shape |

| Applications | Plumbing connections, vibration absorption | Structural components, fixtures |

| Durability | Resistant to fatigue from bending | High strength, resists deformation |

| Installation | Easy to install in tight spaces | Requires precise alignment |

| Cost | Typically higher due to manufacturing process | Generally lower, simpler fabrication |

| Corrosion Resistance | Excellent, suitable for water and gas | Excellent, long-lasting in harsh conditions |

Introduction to Brass: Flexible vs Rigid

Flexible brass tubing offers enhanced adaptability and ease of installation in plumbing and HVAC systems due to its ability to bend without kinking, making it ideal for complex routing in confined spaces. Rigid brass pipe, on the other hand, provides superior structural strength, durability, and reliability in high-pressure applications, commonly used in fixed plumbing installations. The choice between flexible and rigid brass depends on specific project requirements such as routing complexity, pressure capacity, and long-term maintenance considerations.

Defining Flexible Brass

Flexible brass, a copper-zinc alloy with varying amounts of lead and other elements, is designed to achieve increased malleability and tensile strength. Unlike rigid brass, which maintains a fixed shape for structural applications, flexible brass bends without fracturing, making it ideal for components like connectors, springs, and intricate fittings. Its enhanced ductility results from controlled alloy composition and heat treatment, enabling seamless performance in dynamic or vibration-exposed environments.

Characteristics of Rigid Brass

Rigid brass features high tensile strength and exceptional durability due to its dense alloy composition, making it ideal for applications requiring structural integrity. Its low malleability contrasts with flexible brass, offering superior resistance to deformation and maintaining precise shapes under stress. Commonly used in plumbing and industrial fittings, rigid brass withstands high pressure and corrosion, ensuring long-lasting performance in demanding environments.

Manufacturing Processes: Flexible and Rigid Brass

Flexible brass is produced through alloying with components like copper, zinc, and small amounts of lead to enhance malleability, followed by processes such as annealing and cold rolling that increase ductility for bending applications. Rigid brass manufacturing emphasizes higher copper content and minimal lead, utilizing casting and precision machining to achieve a solid, dimensional stability suitable for structural and plumbing components. Both processes rely on controlled thermal treatments and metalworking techniques to tailor mechanical properties specific to either flexibility or rigidity demands.

Mechanical Properties Comparison

Flexible brass exhibits superior ductility and higher tensile strength, allowing it to withstand repeated bending and deformation without fracture. Rigid brass, in contrast, offers greater hardness and stiffness, making it ideal for applications requiring structural stability and resistance to wear. The mechanical property differences between flexible and rigid brass are critical for selecting the appropriate alloy in manufacturing processes like tubing and hardware components.

Applications of Flexible Brass

Flexible brass tubing offers superior adaptability in plumbing and HVAC systems, enabling efficient installation in confined spaces and complex layouts. Its corrosion resistance and excellent thermal conductivity make it ideal for water supply lines, gas distribution, and refrigeration applications. The material's ability to bend without kinking ensures reliability and longevity in residential, commercial, and industrial environments.

Uses of Rigid Brass in Industry

Rigid brass is widely used in industrial applications such as plumbing fittings, electrical connectors, and precision instruments due to its high strength and resistance to corrosion. Its rigidity ensures secure and leak-proof connections in water supply systems and HVAC units, providing durability under high pressure. Industries also rely on rigid brass for manufacturing valves and gears, where consistent dimensional stability is critical for performance.

Pros and Cons: Flexible vs Rigid Brass

Flexible brass offers enhanced adaptability for intricate plumbing or decorative applications due to its ability to bend without breaking, minimizing installation time and reducing the need for additional fittings. Rigid brass provides superior structural strength and durability, ideal for high-pressure systems or load-bearing components, but lacks the versatility and ease of manipulation found in flexible variants. Choosing between flexible and rigid brass depends on project requirements, balancing flexibility and ease of installation against strength and longevity.

Cost Analysis: Flexible vs Rigid Brass

Flexible brass tubing typically incurs higher initial costs compared to rigid brass due to its manufacturing complexities and specialized alloy composition. However, flexible brass often reduces installation expenses by minimizing the need for fittings and allowing easier adjustments, resulting in lower overall project costs. Rigid brass, while cheaper upfront, may increase labor and maintenance expenses over time due to its limited adaptability and higher potential for leaks at connection points.

Choosing the Right Brass Type for Your Project

Flexible brass offers superior versatility and ease of installation, ideal for projects requiring frequent adjustments or intricate bends, such as custom fittings and plumbing configurations. Rigid brass provides exceptional strength and durability, making it suitable for structural applications and environments with high mechanical stress. Assessing your project's requirements for flexibility, pressure tolerance, and longevity ensures the optimal brass type is selected for maximum performance and cost-efficiency.

Flexible Brass vs Rigid Brass Infographic

materialdif.com

materialdif.com