Hot forging brass involves heating the metal above its recrystallization temperature, allowing for easier shaping and improved ductility, which reduces the risk of cracking. Cold forging is performed at or near room temperature, resulting in enhanced strength and surface finish due to work hardening but requires more force and can increase the risk of stress fractures. Choosing between hot and cold forging depends on the desired mechanical properties, component complexity, and production efficiency.

Table of Comparison

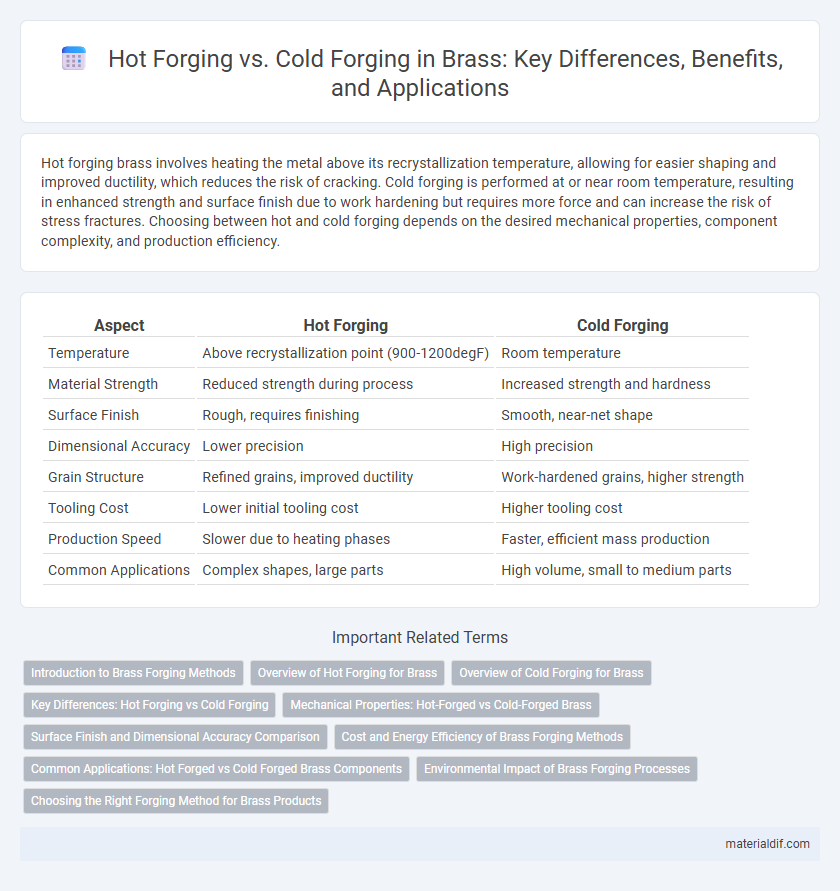

| Aspect | Hot Forging | Cold Forging |

|---|---|---|

| Temperature | Above recrystallization point (900-1200degF) | Room temperature |

| Material Strength | Reduced strength during process | Increased strength and hardness |

| Surface Finish | Rough, requires finishing | Smooth, near-net shape |

| Dimensional Accuracy | Lower precision | High precision |

| Grain Structure | Refined grains, improved ductility | Work-hardened grains, higher strength |

| Tooling Cost | Lower initial tooling cost | Higher tooling cost |

| Production Speed | Slower due to heating phases | Faster, efficient mass production |

| Common Applications | Complex shapes, large parts | High volume, small to medium parts |

Introduction to Brass Forging Methods

Brass forging methods primarily include hot forging and cold forging, each suited to different manufacturing requirements and material properties. Hot forging involves heating brass above its recrystallization temperature, enhancing ductility and allowing complex shapes with improved mechanical strength. Cold forging, performed at or near room temperature, increases brass hardness and surface finish quality, making it ideal for high-precision components with tight tolerances.

Overview of Hot Forging for Brass

Hot forging of brass involves heating the alloy above its recrystallization temperature, typically between 900degF and 1300degF, to enhance its malleability and reduce the risk of cracking. This process refines the grain structure, improving mechanical properties such as strength, ductility, and toughness, which are critical for high-performance brass components. Hot forging also facilitates the production of complex shapes with superior surface finishes and reduces the force required compared to cold forging.

Overview of Cold Forging for Brass

Cold forging of brass involves shaping the metal at room temperature, which enhances its strength and surface finish through work hardening. This process produces precise, high-quality components with excellent dimensional accuracy and improved mechanical properties compared to hot forging. Cold forging minimizes material waste and reduces the need for secondary machining, making it efficient for producing complex brass parts.

Key Differences: Hot Forging vs Cold Forging

Hot forging of brass involves shaping the metal above its recrystallization temperature, enhancing ductility and reducing strain hardening, resulting in improved grain structure and mechanical properties. Cold forging occurs below the recrystallization temperature, increasing strength through strain hardening but often requiring more force and producing a harder surface finish. Hot forging typically allows for more complex shapes and reduced residual stresses compared to the higher precision and surface finish achieved in cold forging.

Mechanical Properties: Hot-Forged vs Cold-Forged Brass

Hot-forged brass exhibits improved ductility and reduced residual stress compared to cold-forged brass, resulting in enhanced impact resistance and fatigue strength. Cold forging increases hardness and tensile strength due to strain hardening but can lead to higher brittleness and the need for subsequent annealing. The choice between hot and cold forging directly influences the mechanical properties of brass components, affecting their suitability for applications requiring either formability or high strength.

Surface Finish and Dimensional Accuracy Comparison

Hot forging of brass provides a coarser surface finish due to oxidation and scale formation at elevated temperatures, while cold forging yields a smoother, more polished surface ideal for aesthetic applications. Cold forging enhances dimensional accuracy by minimizing thermal distortion, making it suitable for precision components, whereas hot forging can result in slight dimensional variations caused by thermal contraction during cooling. The choice between hot and cold forging depends on balancing surface finish requirements with acceptable tolerances in brass manufacturing.

Cost and Energy Efficiency of Brass Forging Methods

Hot forging brass requires higher energy consumption due to the elevated temperatures needed to shape the metal, resulting in increased operational costs compared to cold forging. Cold forging of brass is more energy-efficient, utilizing room temperature deformation that reduces power usage and tooling wear, thereby lowering overall manufacturing expenses. However, hot forging can produce stronger and more ductile parts, which may justify its higher cost in applications demanding superior mechanical properties.

Common Applications: Hot Forged vs Cold Forged Brass Components

Hot forged brass components are commonly used in automotive parts, plumbing fittings, and aerospace applications due to their enhanced mechanical properties and improved grain structure. Cold forged brass parts are favored for electrical connectors, delicate instrumentation, and precision hardware because cold forging provides superior surface finish and dimensional accuracy. The choice between hot and cold forging depends on the required strength, complexity, and surface quality of the brass component.

Environmental Impact of Brass Forging Processes

Hot forging of brass consumes more energy due to the required high temperatures, resulting in a larger carbon footprint compared to cold forging. Cold forging operates at or near room temperature, reducing energy consumption and minimizing greenhouse gas emissions. Waste material is lower in cold forging, promoting higher material efficiency and less environmental pollution.

Choosing the Right Forging Method for Brass Products

Hot forging of brass enhances ductility and reduces the risk of cracking by heating the metal above its recrystallization temperature, making it ideal for complex shapes and large components. Cold forging maintains higher strength and improved surface finish due to work hardening but requires greater force and precise tooling for thinner, simpler parts. Selecting the appropriate method depends on the desired mechanical properties, product complexity, and production volume for optimal brass component performance.

Hot Forging vs Cold Forging Infographic

materialdif.com

materialdif.com