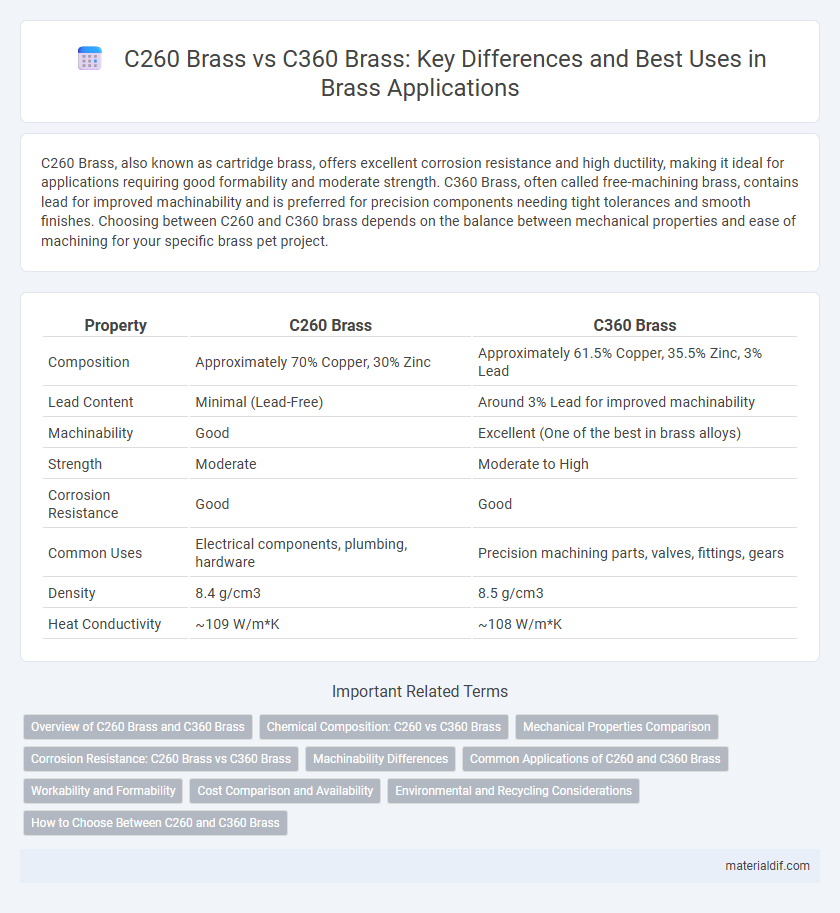

C260 Brass, also known as cartridge brass, offers excellent corrosion resistance and high ductility, making it ideal for applications requiring good formability and moderate strength. C360 Brass, often called free-machining brass, contains lead for improved machinability and is preferred for precision components needing tight tolerances and smooth finishes. Choosing between C260 and C360 brass depends on the balance between mechanical properties and ease of machining for your specific brass pet project.

Table of Comparison

| Property | C260 Brass | C360 Brass |

|---|---|---|

| Composition | Approximately 70% Copper, 30% Zinc | Approximately 61.5% Copper, 35.5% Zinc, 3% Lead |

| Lead Content | Minimal (Lead-Free) | Around 3% Lead for improved machinability |

| Machinability | Good | Excellent (One of the best in brass alloys) |

| Strength | Moderate | Moderate to High |

| Corrosion Resistance | Good | Good |

| Common Uses | Electrical components, plumbing, hardware | Precision machining parts, valves, fittings, gears |

| Density | 8.4 g/cm3 | 8.5 g/cm3 |

| Heat Conductivity | ~109 W/m*K | ~108 W/m*K |

Overview of C260 Brass and C360 Brass

C260 Brass, also known as Cartridge Brass, contains approximately 70% copper and 30% zinc, offering excellent formability and corrosion resistance, making it ideal for precision machining and decorative applications. C360 Brass, with a slightly higher zinc content around 35%, provides superior machinability and strength, widely used in manufacturing components requiring tight tolerances such as fittings and valves. Both alloys exhibit good electrical conductivity but differ in mechanical properties and application suitability based on zinc content and processing characteristics.

Chemical Composition: C260 vs C360 Brass

C260 brass, also known as cartridge brass, contains approximately 70% copper and 30% zinc, providing excellent ductility and corrosion resistance ideal for forming and fabrication. C360 brass, or free-machining brass, has a similar base composition of around 61-63% copper and 35-37% zinc but includes a small amount of lead (about 2.5%) to enhance machinability. The higher zinc content in C360 combined with lead makes it superior in machining applications, while C260 offers better mechanical strength and corrosion resistance due to its higher copper content.

Mechanical Properties Comparison

C260 brass exhibits tensile strength ranging from 70,000 to 75,000 psi and excellent ductility, making it suitable for applications requiring moderate strength and high machinability. C360 brass offers higher tensile strength, typically between 75,000 and 80,000 psi, with superior machinability and better wear resistance due to its increased lead content. Both alloys provide good corrosion resistance, but C360's enhanced mechanical properties make it preferable for precision machining and high-performance components.

Corrosion Resistance: C260 Brass vs C360 Brass

C260 brass, also known as cartridge brass, generally offers better corrosion resistance due to its higher copper content (70%) compared to C360 brass, which contains about 61.5% copper. The increased zinc content in C360 brass can make it more susceptible to dezincification in corrosive environments. For applications requiring superior resistance to atmospheric and chemical corrosion, C260 brass is often preferred.

Machinability Differences

C260 brass, also known as cartridge brass, contains 70% copper and 30% zinc, offering excellent ductility but moderate machinability compared to C360 brass. C360 brass, often referred to as free-machining brass, comprises approximately 61.5% copper, 35.5% zinc, and 3% lead, significantly enhancing machinability due to the lead content which reduces tool wear and improves chip formation. For applications requiring high-speed machining and superior surface finish, C360 brass is generally preferred over C260.

Common Applications of C260 and C360 Brass

C260 brass, also known as cartridge brass, is widely used in applications such as electrical connectors, plumbing fittings, and musical instruments due to its excellent formability and corrosion resistance. C360 brass, recognized for its high machinability, is commonly utilized in precision components like valves, gears, and screws, where intricate detailing and tight tolerances are critical. Both C260 and C360 brass find extensive use in manufacturing industries, with C260 favored for stamping and forming, while C360 excels in machining processes.

Workability and Formability

C260 brass, known as cartridge brass, offers excellent workability and is highly ductile, making it ideal for complex forming processes like deep drawing and bending. C360 brass provides superior formability due to its higher zinc content, allowing for easier machining and shaping into intricate parts. Both alloys are valued in manufacturing, but C360 is preferred for applications requiring tight tolerances and detailed component craftsmanship.

Cost Comparison and Availability

C260 brass, commonly known as cartridge brass, is generally less expensive and more widely available compared to C360 brass, which is free-machining brass with added lead content. The higher machinability of C360 often results in lower processing costs for complex components despite its higher material price, making it cost-effective for precision manufacturing. Availability of C260 is broader in standard sheet and rod forms, while C360 is more specialized and may have longer lead times depending on supplier inventory.

Environmental and Recycling Considerations

C260 brass, primarily composed of 70% copper and 30% zinc, offers favorable recyclability due to its widespread use in plumbing and electrical components, enabling efficient material recovery and reduced environmental impact. C360 brass, with its higher copper content and added lead for machinability, poses more challenges in recycling processes because lead separation requires specialized treatment to prevent environmental contamination. Both alloys contribute to circular economy initiatives by supporting metal reclamation, but C260's simpler composition aligns better with eco-friendly recycling practices and lower lifecycle emissions.

How to Choose Between C260 and C360 Brass

Choosing between C260 brass and C360 brass depends on the application's strength and machinability requirements. C260, known as cartridge brass, offers excellent corrosion resistance and moderate machinability, making it ideal for decorative fittings and electrical components. C360 brass, often called free-machining brass, provides superior machinability due to its lead content, suitable for high-precision machining in automotive and industrial applications.

C260 Brass vs C360 Brass Infographic

materialdif.com

materialdif.com