Yellow brass, composed primarily of copper and zinc, offers excellent machinability and corrosion resistance, making it ideal for plumbing and musical instruments. Red brass contains a higher copper content, giving it superior strength, enhanced corrosion resistance, and a distinct reddish hue, commonly used in marine environments and architectural applications. Both alloys provide unique mechanical and aesthetic properties suited to different industrial needs.

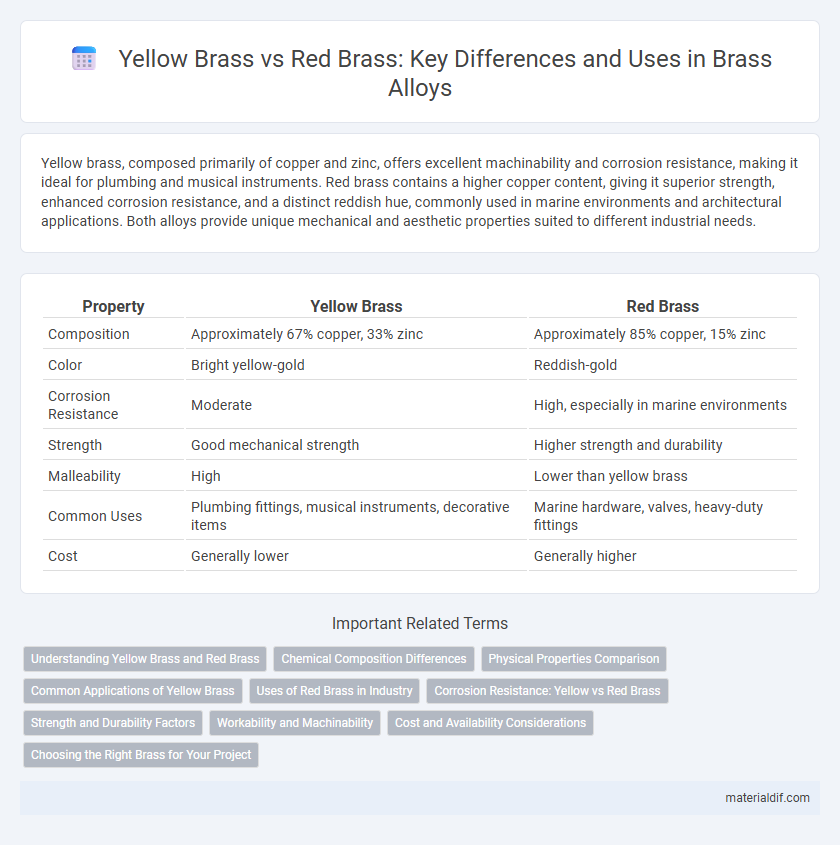

Table of Comparison

| Property | Yellow Brass | Red Brass |

|---|---|---|

| Composition | Approximately 67% copper, 33% zinc | Approximately 85% copper, 15% zinc |

| Color | Bright yellow-gold | Reddish-gold |

| Corrosion Resistance | Moderate | High, especially in marine environments |

| Strength | Good mechanical strength | Higher strength and durability |

| Malleability | High | Lower than yellow brass |

| Common Uses | Plumbing fittings, musical instruments, decorative items | Marine hardware, valves, heavy-duty fittings |

| Cost | Generally lower | Generally higher |

Understanding Yellow Brass and Red Brass

Yellow brass typically contains 60-70% copper and 30-40% zinc, giving it a bright, golden appearance with excellent machinability and corrosion resistance for general applications. Red brass generally features around 85% copper and 5-10% zinc, with small amounts of lead or tin, offering superior strength, corrosion resistance, and thermal conductivity ideal for plumbing and marine environments. Understanding the distinct copper and zinc ratios in yellow and red brass helps select the appropriate alloy based on mechanical properties and environmental durability.

Chemical Composition Differences

Yellow brass primarily consists of approximately 60-70% copper and 30-40% zinc, with trace amounts of lead to enhance machinability. Red brass contains a higher copper content, about 85%, combined with 5% zinc and 5% lead, which gives it a distinctive reddish hue and improved corrosion resistance. The variations in copper and zinc ratios directly influence the mechanical properties and color of yellow brass versus red brass.

Physical Properties Comparison

Yellow brass, composed primarily of copper and zinc with zinc content around 30%, exhibits high strength, good corrosion resistance, and excellent machinability, making it ideal for plumbing and musical instruments. Red brass, containing a higher copper content (approximately 85%) with small amounts of lead for improved machinability, offers superior corrosion resistance, especially in marine environments, and maintains good ductility and thermal conductivity. Both alloys differ significantly in tensile strength, with yellow brass typically ranging from 320 to 440 MPa and red brass around 380 to 480 MPa, while red brass generally shows better wear resistance and longer service life under harsh conditions.

Common Applications of Yellow Brass

Yellow brass, an alloy of copper and zinc with a higher zinc content, is widely used in plumbing fittings, musical instruments, and decorative hardware due to its excellent corrosion resistance and bright gold-like appearance. Its machinability and strength make it ideal for screws, valves, and gears in automotive and industrial applications. Yellow brass is also favored in electrical connectors for its good conductivity and durability.

Uses of Red Brass in Industry

Red brass, composed primarily of copper and zinc with a higher copper content than yellow brass, is widely used in plumbing, electrical connectors, and marine hardware due to its superior corrosion resistance and strength. Its excellent machinability and thermal conductivity make it ideal for precision components in instrumentation and valve manufacturing. The alloy's durability in harsh environments ensures reliable performance in industrial applications where exposure to saltwater and mechanical stress is common.

Corrosion Resistance: Yellow vs Red Brass

Yellow brass, composed primarily of copper and zinc, offers moderate corrosion resistance suitable for general applications, while red brass, containing higher copper content with added lead or tin, exhibits superior corrosion resistance, especially in marine and plumbing environments. The enhanced copper percentage in red brass forms a more stable oxide layer, protecting against rust and environmental degradation better than yellow brass. Choosing red brass ensures longevity and durability in corrosive settings compared to the relatively less resistant yellow brass.

Strength and Durability Factors

Yellow brass, typically composed of 60-70% copper and 30-40% zinc, offers excellent strength and moderate durability, making it suitable for general applications such as plumbing and musical instruments. Red brass, containing about 85% copper and 15% zinc, provides superior corrosion resistance and higher tensile strength, enhancing its durability in harsh environments like marine fittings. The increased copper content in red brass significantly contributes to its robustness and resistance to wear compared to yellow brass.

Workability and Machinability

Yellow brass, composed primarily of copper and zinc with about 65-70% copper, offers excellent machinability due to its uniform grain structure and lower hardness. Red brass, containing a higher copper content of around 85% and small amounts of lead or tin, provides superior workability with enhanced ductility and corrosion resistance. Both alloys perform well in machining, but yellow brass is preferred for precision components, while red brass excels in applications requiring intricate shaping and durability.

Cost and Availability Considerations

Yellow brass, typically composed of approximately 67% copper and 33% zinc, is more widely available and generally less expensive due to its simpler alloy composition and higher zinc content. Red brass, containing about 85% copper and 15% zinc with a distinctive reddish tint, tends to be costlier and less readily available because of its higher copper percentage and specific uses in plumbing and marine applications. The cost difference reflects both the metal content and market demand, making yellow brass a more economical choice for general manufacturing needs.

Choosing the Right Brass for Your Project

Yellow brass, composed primarily of copper and zinc with around 65-70% copper content, offers excellent machinability and corrosion resistance, making it ideal for decorative and architectural applications. Red brass contains about 85% copper, providing superior strength and corrosion resistance, especially in marine environments, suitable for plumbing and industrial uses requiring durability. Selecting the right brass depends on balancing factors like mechanical strength, corrosion resistance, and appearance to match specific project requirements.

Yellow Brass vs Red Brass Infographic

materialdif.com

materialdif.com