DZR Brass, or Dezincification Resistant Brass, offers superior corrosion resistance compared to standard brass, making it ideal for plumbing applications involving potable water. Its enhanced alloy composition prevents dezincification, which can compromise the structural integrity of fittings over time. Standard brass, while cost-effective, is more susceptible to corrosion in aggressive water environments, limiting its durability and lifespan.

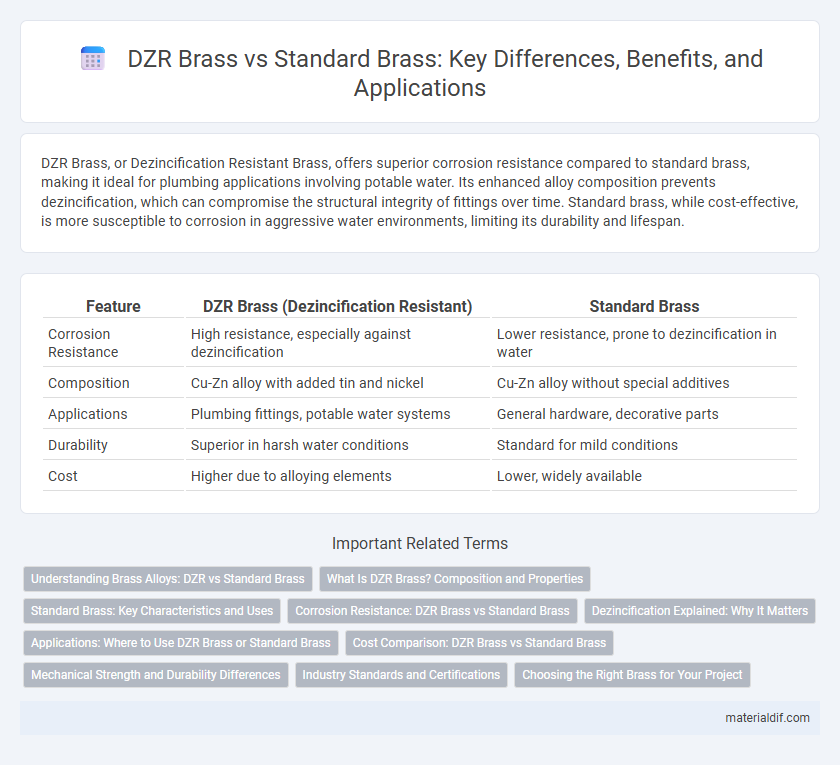

Table of Comparison

| Feature | DZR Brass (Dezincification Resistant) | Standard Brass |

|---|---|---|

| Corrosion Resistance | High resistance, especially against dezincification | Lower resistance, prone to dezincification in water |

| Composition | Cu-Zn alloy with added tin and nickel | Cu-Zn alloy without special additives |

| Applications | Plumbing fittings, potable water systems | General hardware, decorative parts |

| Durability | Superior in harsh water conditions | Standard for mild conditions |

| Cost | Higher due to alloying elements | Lower, widely available |

Understanding Brass Alloys: DZR vs Standard Brass

DZR brass, or dezincification-resistant brass, contains a higher percentage of copper and special alloying elements like arsenic, enhancing its resistance to dezincification compared to standard brass. Standard brass alloys typically consist of around 60-70% copper and 30-40% zinc but lack the protective additives that prevent dezincification in harsh environments. Understanding these compositional differences is crucial for selecting the right brass alloy in plumbing and industrial applications requiring long-term corrosion resistance.

What Is DZR Brass? Composition and Properties

DZR Brass, or Dezincification Resistant Brass, is an alloy specifically engineered to resist dezincification by reducing zinc content and adding elements like arsenic, antimony, or phosphorus. Its composition typically consists of around 60% copper, 39% zinc, and small amounts of these additives, enhancing its corrosion resistance in water applications. This alloy maintains mechanical strength and durability while preventing the porous degradation common in standard brass, making it ideal for plumbing and marine environments.

Standard Brass: Key Characteristics and Uses

Standard Brass, an alloy primarily composed of copper and zinc, is renowned for its excellent machinability and moderate corrosion resistance, making it suitable for general plumbing, musical instruments, and decorative hardware. Its versatility and cost-effectiveness contribute to widespread use in applications where extreme resistance to dezincification is not critical. Standard Brass maintains good thermal and electrical conductivity, supporting diverse manufacturing processes and functional requirements.

Corrosion Resistance: DZR Brass vs Standard Brass

DZR brass, also known as dezincification-resistant brass, significantly outperforms standard brass in corrosion resistance due to its specialized alloy composition that minimizes dezincification and protects against stress corrosion cracking. Standard brass, primarily composed of copper and zinc, is prone to dezincification when exposed to water and humid environments, leading to weakening and potential failure. DZR brass is the preferred material for plumbing and marine applications where enhanced longevity and durability against corrosive elements are crucial.

Dezincification Explained: Why It Matters

DZR Brass (Dezincification Resistant Brass) is engineered to prevent the dezincification process, which involves the selective leaching of zinc from standard brass alloys, leading to structural weakness and corrosion. This resistance is critical in plumbing and marine applications where exposure to water and corrosive environments can accelerate material degradation. Choosing DZR Brass ensures enhanced durability, longevity, and safety in installations prone to dezincification.

Applications: Where to Use DZR Brass or Standard Brass

DZR Brass is ideal for applications requiring high resistance to dezincification and corrosion, such as plumbing fittings, valve components, and marine environments where water exposure is frequent. Standard Brass suits decorative hardware, musical instruments, and general-purpose applications with low exposure to corrosive conditions. Choosing DZR Brass ensures durability in potable water systems, while Standard Brass offers cost-effective solutions for non-corrosive indoor uses.

Cost Comparison: DZR Brass vs Standard Brass

DZR brass, known for its enhanced corrosion resistance and durability in plumbing applications, generally commands a higher price compared to standard brass due to its specialized dezincification-resistant alloy composition. The initial cost of DZR brass is offset by its longer lifespan and reduced maintenance requirements, making it a cost-effective choice in environments prone to water corrosion and chemical exposure. Standard brass, while more affordable upfront, may incur higher replacement and repair costs over time in aggressive environments where dezincification leads to premature failure.

Mechanical Strength and Durability Differences

DZR (Dezincification Resistant) brass exhibits superior mechanical strength compared to standard brass due to its engineered alloy composition that reduces zinc content and increases copper, enhancing tensile strength and hardness. The durability of DZR brass is significantly higher as it resists corrosion and dezincification, which are common degradation mechanisms in standard brass, ensuring longer service life in harsh environments. Industrial applications benefiting from DZR brass include plumbing fixtures and marine components where enhanced mechanical integrity and corrosion resistance are critical.

Industry Standards and Certifications

DZR Brass complies with strict industry standards such as BS EN 12165 CW602N and NSF/ANSI 61 certification, ensuring superior corrosion resistance and suitability for potable water applications. Standard Brass, typically made to BS EN 12164 CW617N, lacks the dezincification resistance required for long-term water system reliability. Certifications like WRAS and NSF validate DZR Brass's adherence to health and safety regulations in plumbing and industrial use.

Choosing the Right Brass for Your Project

DZR Brass (Dezincification Resistant Brass) offers superior corrosion resistance and enhanced durability compared to standard brass, making it ideal for plumbing and marine applications exposed to water. Standard brass, while more cost-effective, tends to suffer from dezincification, leading to weakened structural integrity in high-moisture environments. Selecting DZR Brass ensures long-term reliability and reduced maintenance for projects requiring robust performance against corrosion.

DZR Brass vs Standard Brass Infographic

materialdif.com

materialdif.com