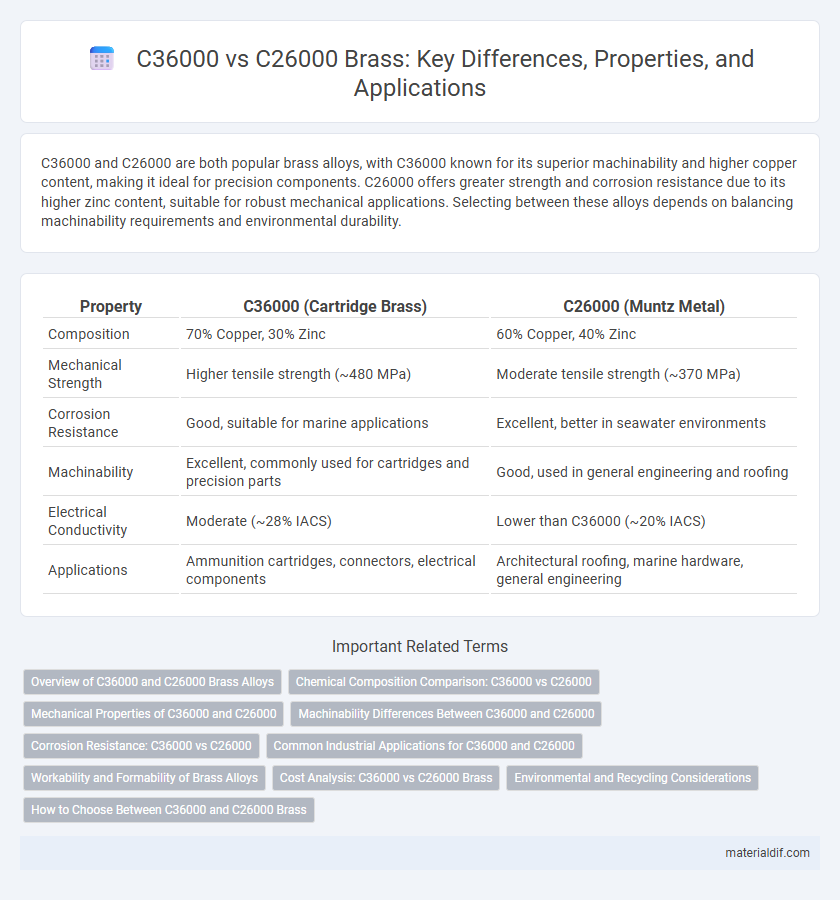

C36000 and C26000 are both popular brass alloys, with C36000 known for its superior machinability and higher copper content, making it ideal for precision components. C26000 offers greater strength and corrosion resistance due to its higher zinc content, suitable for robust mechanical applications. Selecting between these alloys depends on balancing machinability requirements and environmental durability.

Table of Comparison

| Property | C36000 (Cartridge Brass) | C26000 (Muntz Metal) |

|---|---|---|

| Composition | 70% Copper, 30% Zinc | 60% Copper, 40% Zinc |

| Mechanical Strength | Higher tensile strength (~480 MPa) | Moderate tensile strength (~370 MPa) |

| Corrosion Resistance | Good, suitable for marine applications | Excellent, better in seawater environments |

| Machinability | Excellent, commonly used for cartridges and precision parts | Good, used in general engineering and roofing |

| Electrical Conductivity | Moderate (~28% IACS) | Lower than C36000 (~20% IACS) |

| Applications | Ammunition cartridges, connectors, electrical components | Architectural roofing, marine hardware, general engineering |

Overview of C36000 and C26000 Brass Alloys

C36000 brass, also known as free-machining or cartridge brass, contains approximately 60% copper and 40% zinc, making it highly valued for excellent machinability and corrosion resistance. C26000 brass, commonly called commercial or yellow brass, typically has around 70% copper and 30% zinc, offering superior strength and good corrosion resistance but less machinability than C36000. Both alloys find extensive use in industrial applications, with C36000 preferred for precision machining and C26000 favored for structural components.

Chemical Composition Comparison: C36000 vs C26000

C36000 brass, commonly known as free-machining brass, contains approximately 61.5% copper, 35.7% zinc, and a small lead content around 2.8%, enhancing machinability. In contrast, C26000, or cartridge brass, consists of about 70% copper and 30% zinc with minimal lead, offering higher strength but reduced machinability. The primary chemical difference lies in the lead addition in C36000, which significantly improves machining efficiency without compromising corrosion resistance.

Mechanical Properties of C36000 and C26000

C36000 brass, known as free-machining brass, exhibits higher tensile strength typically around 70,000 psi and improved hardness compared to C26000 brass, which usually has a tensile strength near 55,000 psi. The enhanced mechanical properties of C36000 result from its higher lead content, providing better machinability without significantly compromising ductility. C26000, also called cartridge brass, offers superior ductility and corrosion resistance but lower strength, making it suitable for applications requiring moderate mechanical stress.

Machinability Differences Between C36000 and C26000

C36000 brass, also known as free-machining brass, contains approximately 61.5% copper, 35.5% zinc, and 3% lead, which significantly enhances its machinability compared to C26000 brass, composed mainly of 70% copper and 30% zinc without lead. The lead content in C36000 acts as a lubricant during machining processes, reducing tool wear and allowing for faster cutting speeds and better surface finishes. In contrast, C26000 exhibits lower machinability due to the absence of lead, resulting in increased tool wear and slower machining rates.

Corrosion Resistance: C36000 vs C26000

C36000 brass exhibits superior corrosion resistance compared to C26000 due to its higher copper content, typically around 61.5%, which enhances its durability in moist and industrial environments. C26000, with a lower copper content near 59%, shows increased susceptibility to dezincification and surface oxidation over prolonged exposure. Choosing C36000 brass improves longevity in applications requiring enhanced resistance to tarnishing and corrosive agents.

Common Industrial Applications for C36000 and C26000

C36000 brass, known as cartridge brass with 60% copper and 40% zinc, is widely used in precision engineering applications such as electrical connectors, ammunition casings, and plumbing fittings due to its excellent machinability and corrosion resistance. C26000 brass, also called commercial bronze or yellow brass with 70% copper and 30% zinc, is commonly employed in automotive parts, architectural hardware, and marine components where higher strength and better corrosion resistance are critical. Both alloys serve diverse industrial purposes, with C36000 favored for detailed machining tasks and C26000 preferred for robust structural applications.

Workability and Formability of Brass Alloys

C36000 brass, also known as free-machining brass, offers superior workability due to its lead content, which enhances machinability and reduces tool wear, making it ideal for complex shaping and high-speed production. In contrast, C26000 brass, or cartridge brass, contains less lead and exhibits greater formability, allowing for easier cold working and forming operations such as bending, drawing, and stamping. Selecting between C36000 and C26000 depends on whether the priority is efficient machining or advanced forming capabilities in brass alloy applications.

Cost Analysis: C36000 vs C26000 Brass

C36000 brass, also known as cartridge brass, typically costs more than C26000 due to its higher copper content of about 60%, which enhances its machinability and corrosion resistance. C26000 brass contains approximately 70% copper, making it less expensive but with reduced mechanical strength and wear resistance compared to C36000. Cost analysis favors C26000 for budget-sensitive applications, while C36000 is preferred for precision components requiring superior performance and durability.

Environmental and Recycling Considerations

C36000 brass, composed mainly of 60% copper and 40% zinc, offers better recyclability due to its consistent alloy composition, reducing contamination during recycling processes. C26000 brass, often called cartridge brass with approximately 70% copper, has a higher copper content which can increase energy consumption during recycling because copper requires more energy to melt and refine. Choosing C36000 supports more efficient recycling workflows and minimizes environmental impact by facilitating material reuse and reducing waste in metal recovery systems.

How to Choose Between C36000 and C26000 Brass

Choosing between C36000 and C26000 brass depends primarily on machinability and application requirements. C36000 brass, also known as free-machining brass, contains a higher lead content, making it ideal for precision machining and complex components. In contrast, C26000 brass offers superior corrosion resistance and strength, suited for plumbing and marine uses where durability is critical.

C36000 vs C26000 Infographic

materialdif.com

materialdif.com