Rolled brass offers superior strength and uniformity due to its manufacturing process that involves compressing brass into sheets or coils, making it ideal for applications requiring durability and precision. Cast brass, formed by pouring molten metal into molds, provides intricate shapes and detailed designs but often has lower mechanical strength and can be more prone to imperfections. Choosing between rolled brass and cast brass depends on the specific requirements for strength, detail, and production volume in a project.

Table of Comparison

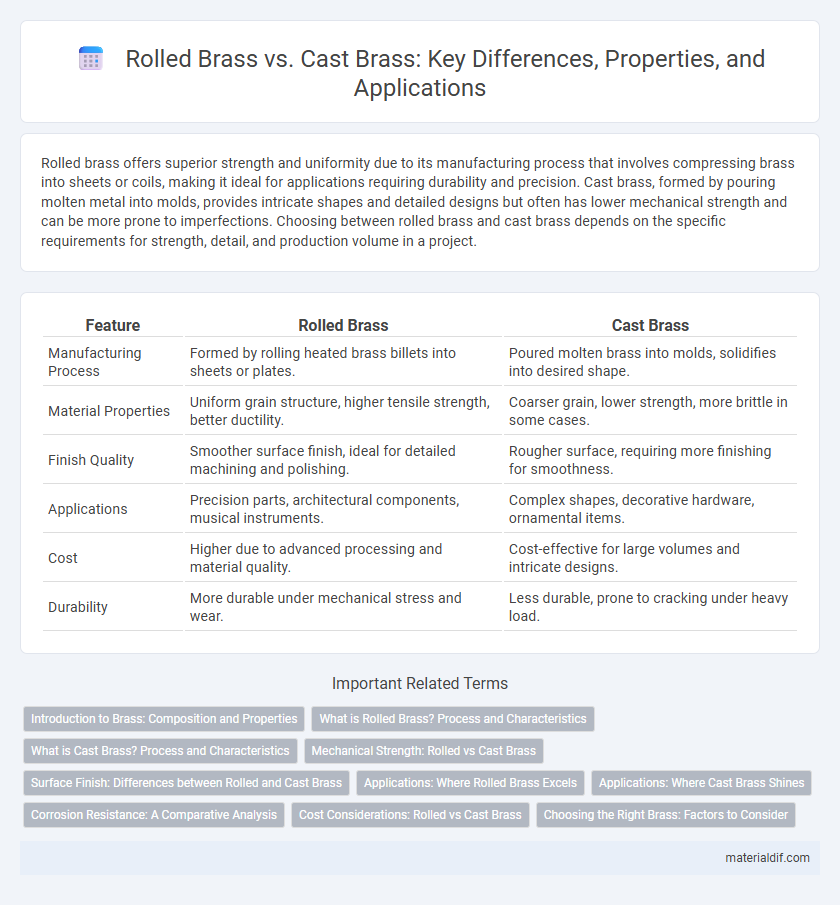

| Feature | Rolled Brass | Cast Brass |

|---|---|---|

| Manufacturing Process | Formed by rolling heated brass billets into sheets or plates. | Poured molten brass into molds, solidifies into desired shape. |

| Material Properties | Uniform grain structure, higher tensile strength, better ductility. | Coarser grain, lower strength, more brittle in some cases. |

| Finish Quality | Smoother surface finish, ideal for detailed machining and polishing. | Rougher surface, requiring more finishing for smoothness. |

| Applications | Precision parts, architectural components, musical instruments. | Complex shapes, decorative hardware, ornamental items. |

| Cost | Higher due to advanced processing and material quality. | Cost-effective for large volumes and intricate designs. |

| Durability | More durable under mechanical stress and wear. | Less durable, prone to cracking under heavy load. |

Introduction to Brass: Composition and Properties

Brass, an alloy primarily composed of copper and zinc, exhibits varying properties depending on its manufacturing process, such as rolled or cast brass. Rolled brass, produced by mechanically compressing heated brass billets, offers superior strength, durability, and a smooth finish, making it ideal for applications requiring precision and wear resistance. Cast brass, formed by pouring molten alloy into molds, provides enhanced design flexibility and complex shapes but generally has lower mechanical strength and a coarser grain structure compared to rolled brass.

What is Rolled Brass? Process and Characteristics

Rolled brass is produced by hot rolling or cold rolling brass billets into flat sheets or coils, enhancing its strength and surface finish through mechanical deformation. This process aligns the metal's grain structure, resulting in improved durability, corrosion resistance, and a consistent thickness ideal for precise machining and fabrication. Rolled brass typically exhibits superior mechanical properties compared to cast brass, making it suitable for applications requiring high tensile strength and uniformity.

What is Cast Brass? Process and Characteristics

Cast brass is produced by melting brass alloy and pouring it into molds, allowing it to solidify into precise shapes with complex geometries. This process results in products with excellent corrosion resistance, enhanced durability, and superior machinability compared to rolled brass. Cast brass often exhibits a finer grain structure, improving its aesthetic appeal and mechanical properties for applications in plumbing, decorative items, and musical instruments.

Mechanical Strength: Rolled vs Cast Brass

Rolled brass demonstrates superior mechanical strength compared to cast brass due to its grain structure alignment from the rolling process, enhancing tensile and yield strength. Cast brass tends to have a more brittle microstructure with internal porosity, making it less resistant to impact and fatigue. For applications demanding high durability and structural integrity, rolled brass is the preferred material.

Surface Finish: Differences between Rolled and Cast Brass

Rolled brass exhibits a smoother, more uniform surface finish due to the metal being compressed and elongated under tension, resulting in enhanced strength and a finer grain structure. Cast brass, produced by pouring molten metal into molds, typically has a rougher texture with visible casting marks and slight surface inconsistencies. These differences in surface finish influence the aesthetic quality and suitability of each brass type for applications requiring precision and visual appeal.

Applications: Where Rolled Brass Excels

Rolled brass offers exceptional strength and uniformity, making it ideal for precision applications such as musical instruments, decorative hardware, and electrical components. Its enhanced durability and smooth finish excel in environments requiring high tensile strength and resistance to wear. Rolled brass's superior machinability and consistent thickness support intricate fabrication processes in architectural and automotive industries.

Applications: Where Cast Brass Shines

Cast brass excels in applications requiring intricate shapes and detailed designs, such as decorative hardware, musical instruments, and precision components. Its superior fluidity during casting allows for complex geometries that rolled brass cannot easily achieve, making it ideal for artistic and architectural elements. Industries like plumbing, automotive, and electrical frequently utilize cast brass for durable, customizable parts with excellent corrosion resistance.

Corrosion Resistance: A Comparative Analysis

Rolled brass exhibits superior corrosion resistance due to its dense, uniform grain structure formed under high pressure, which limits exposure to corrosive elements. Cast brass, while versatile in complex shapes, contains microscopic porosities that can trap moisture, making it more susceptible to oxidation and degradation over time. This fundamental difference makes rolled brass preferable for marine and industrial applications where long-term durability against corrosion is critical.

Cost Considerations: Rolled vs Cast Brass

Rolled brass typically offers a lower production cost due to its efficient manufacturing process involving rolling and pressing, making it ideal for large-volume applications requiring uniform thickness and strength. Cast brass, produced through molten metal poured into molds, tends to be more expensive upfront because of complex casting techniques and longer cooling times, but provides greater design flexibility for intricate shapes. Cost considerations between rolled and cast brass ultimately depend on the balance between production volume, design complexity, and material properties required for the application.

Choosing the Right Brass: Factors to Consider

Choosing the right brass involves evaluating applications where strength, machinability, and finish are critical; rolled brass offers superior durability and a smoother surface ideal for precision parts, while cast brass provides design flexibility for complex shapes at a lower cost. Consider mechanical properties like tensile strength and corrosion resistance, where rolled brass typically outperforms due to its work-hardened grain structure. Cost efficiency, production volume, and aesthetic requirements also influence the decision, making rolled brass suitable for high-performance components and cast brass favorable for artistic or low-volume projects.

Rolled Brass vs Cast Brass Infographic

materialdif.com

materialdif.com