Extruded brass features a consistent grain structure and smooth surface finish, making it ideal for applications requiring precise dimensions and corrosion resistance. Forged brass offers superior strength and durability due to its compressed grain pattern, which enhances mechanical properties for high-stress environments. Choosing between extruded and forged brass depends on whether dimensional accuracy or structural integrity is the primary requirement.

Table of Comparison

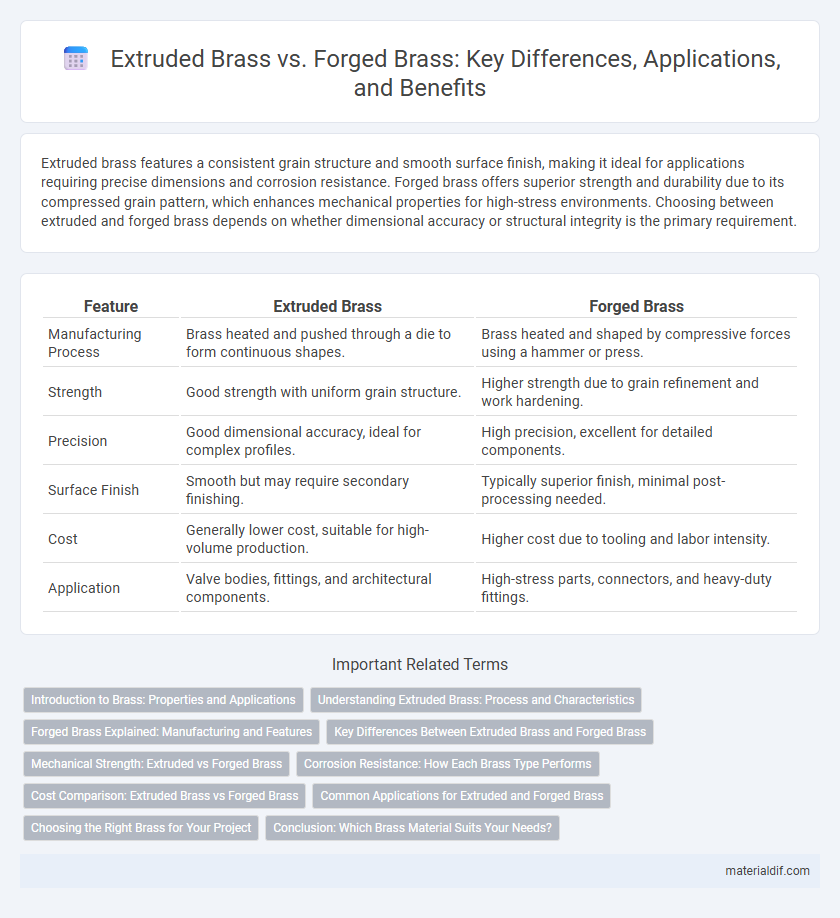

| Feature | Extruded Brass | Forged Brass |

|---|---|---|

| Manufacturing Process | Brass heated and pushed through a die to form continuous shapes. | Brass heated and shaped by compressive forces using a hammer or press. |

| Strength | Good strength with uniform grain structure. | Higher strength due to grain refinement and work hardening. |

| Precision | Good dimensional accuracy, ideal for complex profiles. | High precision, excellent for detailed components. |

| Surface Finish | Smooth but may require secondary finishing. | Typically superior finish, minimal post-processing needed. |

| Cost | Generally lower cost, suitable for high-volume production. | Higher cost due to tooling and labor intensity. |

| Application | Valve bodies, fittings, and architectural components. | High-stress parts, connectors, and heavy-duty fittings. |

Introduction to Brass: Properties and Applications

Extruded brass offers uniform mechanical properties and superior dimensional accuracy ideal for complex profiles in electrical connectors and architectural components. Forged brass exhibits enhanced strength and durability due to its grain flow alignment, making it suitable for heavy-duty fittings and valve applications. Both extrusion and forging leverage brass's excellent corrosion resistance, electrical conductivity, and machinability, expanding its use across plumbing, automotive, and decorative industries.

Understanding Extruded Brass: Process and Characteristics

Extruded brass is produced by forcing heated brass billets through a die to create long, continuous shapes with uniform cross-sections, enhancing material consistency and reducing waste. This process results in brass with excellent mechanical properties such as improved strength and ductility, making it ideal for complex profiles and precision components. Compared to forged brass, extruded brass offers superior surface finish and dimensional accuracy, especially suited for applications in plumbing, automotive parts, and electrical connectors.

Forged Brass Explained: Manufacturing and Features

Forged brass is produced by shaping heated brass billets under high pressure, resulting in a dense, durable material with enhanced mechanical properties such as increased strength and resistance to fatigue. This manufacturing process refines the grain structure, improving the metal's rigidity and making it ideal for high-stress applications like valves, fittings, and hardware components. Forged brass typically offers superior dimensional accuracy and surface finish compared to extruded brass, ensuring reliability and longevity in demanding industrial environments.

Key Differences Between Extruded Brass and Forged Brass

Extruded brass is formed by forcing heated brass billet through a die, resulting in consistent cross-sectional profiles and smooth surface finishes ideal for tubing and complex shapes. Forged brass undergoes localized compressive forces, producing parts with superior strength, density, and grain structure, beneficial for high-stress applications like valves and fittings. The key differences between extruded and forged brass lie in mechanical properties, surface quality, and suitable applications, with forging offering enhanced durability and extrusion providing design flexibility.

Mechanical Strength: Extruded vs Forged Brass

Forged brass exhibits superior mechanical strength compared to extruded brass due to its refined grain structure resulting from the forging process, which enhances durability and resistance to impact. Extruded brass, while easier to shape and suitable for complex profiles, typically has lower tensile strength and hardness because of the continuous grain flow disruption during extrusion. Engineers prioritize forged brass in applications demanding high structural integrity, such as in heavy-duty fittings and high-pressure valve components.

Corrosion Resistance: How Each Brass Type Performs

Extruded brass exhibits superior corrosion resistance due to its uniform grain structure, which minimizes surface defects where corrosion typically initiates. Forged brass, while mechanically stronger, often contains more internal stresses and surface inconsistencies that can reduce its resistance to corrosive environments. Both types perform well in standard applications, but extruded brass is preferable for environments with high moisture or chemical exposure.

Cost Comparison: Extruded Brass vs Forged Brass

Extruded brass typically offers a lower cost compared to forged brass due to its efficient manufacturing process, which reduces material waste and production time. Forged brass involves higher labor and energy expenses, leading to increased overall costs and making it more suitable for applications requiring superior strength and durability. Cost-sensitive projects often favor extruded brass for its affordability while maintaining adequate mechanical properties for many industrial uses.

Common Applications for Extruded and Forged Brass

Extruded brass is commonly used in plumbing fittings, electrical connectors, and architectural hardware due to its precise shapes and smooth surfaces. Forged brass finds frequent application in valves, fasteners, and heavy-duty mechanical components where strength and durability are critical. Both materials are essential in manufacturing, with extruded brass favored for detailed profiles and forged brass preferred for high-stress environments.

Choosing the Right Brass for Your Project

Extruded brass provides consistent cross-sectional shapes ideal for complex designs and lightweight applications, offering excellent machinability and surface finish. Forged brass exhibits superior strength and durability due to its dense grain structure, making it suitable for high-stress or load-bearing projects. Selecting between extruded and forged brass depends on factors like mechanical requirements, part complexity, and cost efficiency tailored to your specific project needs.

Conclusion: Which Brass Material Suits Your Needs?

Extruded brass offers excellent dimensional accuracy and is ideal for complex shapes requiring tight tolerances, making it suitable for detailed mechanical parts and precision fittings. Forged brass provides superior strength and durability due to its denser grain structure, fitting applications subjected to high stress or wear, such as heavy-duty valves and fasteners. Choosing between extruded and forged brass depends on whether your priority lies in intricate design precision or enhanced mechanical robustness for demanding environments.

Extruded Brass vs Forged Brass Infographic

materialdif.com

materialdif.com