Extruded brass offers enhanced strength and uniformity due to the continuous pushing process through a die, making it ideal for complex shapes and heavy-duty applications. Drawn brass, produced by pulling the material through a die, provides improved surface finish and dimensional accuracy, suitable for precision components. Both methods optimize brass properties but serve different manufacturing needs based on shape complexity and tolerance requirements.

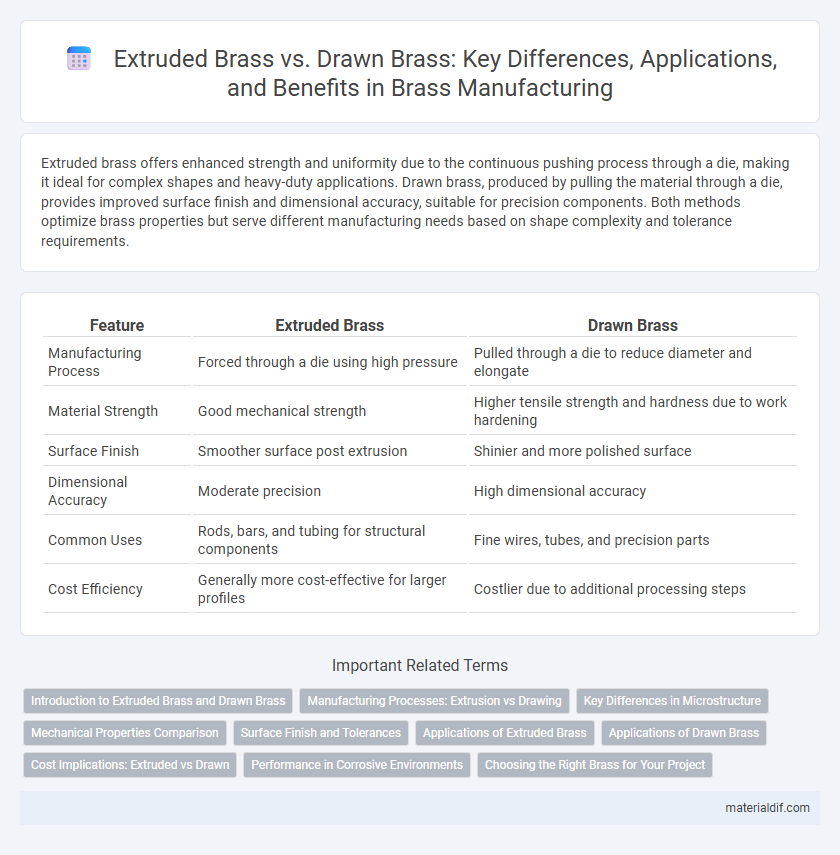

Table of Comparison

| Feature | Extruded Brass | Drawn Brass |

|---|---|---|

| Manufacturing Process | Forced through a die using high pressure | Pulled through a die to reduce diameter and elongate |

| Material Strength | Good mechanical strength | Higher tensile strength and hardness due to work hardening |

| Surface Finish | Smoother surface post extrusion | Shinier and more polished surface |

| Dimensional Accuracy | Moderate precision | High dimensional accuracy |

| Common Uses | Rods, bars, and tubing for structural components | Fine wires, tubes, and precision parts |

| Cost Efficiency | Generally more cost-effective for larger profiles | Costlier due to additional processing steps |

Introduction to Extruded Brass and Drawn Brass

Extruded brass is produced by forcing heated brass billets through a die to create long, continuous shapes with uniform cross-sections, offering excellent mechanical properties and versatility for complex profiles. Drawn brass involves pulling brass rods through a series of dies to reduce diameter and increase strength, resulting in precise dimensions and improved surface finish suitable for high-tolerance applications. Both processes optimize brass material properties to meet specific industrial requirements in construction, automotive, and electronics manufacturing.

Manufacturing Processes: Extrusion vs Drawing

Extruded brass is produced by forcing heated brass billet through a die, creating uniform cross-sections with excellent structural integrity and minimal waste. Drawn brass involves pulling a brass rod or tube through progressively smaller dies at room temperature, enhancing strength and surface finish through work hardening. The extrusion process is ideal for complex shapes and larger profiles, while drawing excels in producing precise, high-strength components with tight dimensional tolerances.

Key Differences in Microstructure

Extruded brass exhibits a coarser grain structure due to the metal being forced through a die, resulting in improved machinability and ductility. In contrast, drawn brass undergoes a cold working process that refines its microstructure, producing elongated grains aligned in the direction of drawing, which enhances strength and hardness. These microstructural differences directly influence the mechanical properties and suitability of extruded and drawn brass for specific industrial applications.

Mechanical Properties Comparison

Extruded brass typically exhibits higher tensile strength and improved ductility compared to drawn brass due to its controlled deformation process during extrusion, which refines the grain structure. Drawn brass, however, often has superior surface finish and dimensional accuracy, making it ideal for precision applications but usually at the cost of slightly reduced mechanical strength. The mechanical properties of extruded brass include greater hardness and yield strength, while drawn brass tends to offer better elongation and fatigue resistance depending on the specific alloy composition and processing conditions.

Surface Finish and Tolerances

Extruded brass typically exhibits a smoother surface finish due to the continuous pushing process, resulting in fewer surface imperfections and a more uniform texture ideal for visible applications. Drawn brass offers tighter dimensional tolerances as the material is pulled through dies, allowing for more precise control over thickness and shape, which is crucial for components requiring exact specifications. Both processes yield high-quality brass products, but extruded brass is favored for aesthetics while drawn brass excels in precision and consistency.

Applications of Extruded Brass

Extruded brass is widely used in manufacturing components requiring complex cross-sectional shapes, such as plumbing fittings, valves, and electrical connectors, due to its excellent machinability and strength. Its uniform grain structure and improved mechanical properties make it ideal for applications demanding high corrosion resistance and durability in automotive and aerospace industries. The versatility of extruded brass also extends to decorative hardware and musical instruments, where precision and aesthetic finish are critical.

Applications of Drawn Brass

Drawn brass offers superior dimensional accuracy and enhanced mechanical properties, making it ideal for precision applications such as electrical connectors, musical instruments, and intricate hardware components. Its fine surface finish and uniform grain structure enable reliable performance in environments demanding high strength and corrosion resistance. Industries like automotive, aerospace, and electronics frequently utilize drawn brass for producing detailed parts requiring tight tolerances and durability.

Cost Implications: Extruded vs Drawn

Extruded brass generally incurs lower production costs due to simpler manufacturing processes and higher output efficiency, making it more cost-effective for large-scale projects. Drawn brass, involving more intricate shaping through pulling the metal through dies, results in higher material and labor expenses, impacting overall pricing. Cost implications vary based on application precision requirements, with extruded brass favored for bulk applications and drawn brass preferred where tighter dimensional tolerances justify increased expenditure.

Performance in Corrosive Environments

Extruded brass exhibits enhanced corrosion resistance due to its uniform grain structure formed during the extrusion process, making it ideal for harsh, corrosive environments. Drawn brass, while offering superior tensile strength and dimensional accuracy, can develop micro-cracks during the drawing process that may accelerate corrosion under aggressive conditions. Selecting extruded brass maximizes durability and longevity in applications exposed to moisture, chemicals, and saltwater, outperforming drawn brass where corrosion resistance is critical.

Choosing the Right Brass for Your Project

Extruded brass offers greater versatility and strength due to its continuous shape formation, making it ideal for structural components requiring complex profiles. Drawn brass provides superior surface finish and tighter tolerances, perfect for precision parts such as electrical connectors and decorative items. Selecting the right brass depends on project requirements like mechanical strength, dimensional accuracy, and aesthetic quality.

Extruded Brass vs Drawn Brass Infographic

materialdif.com

materialdif.com