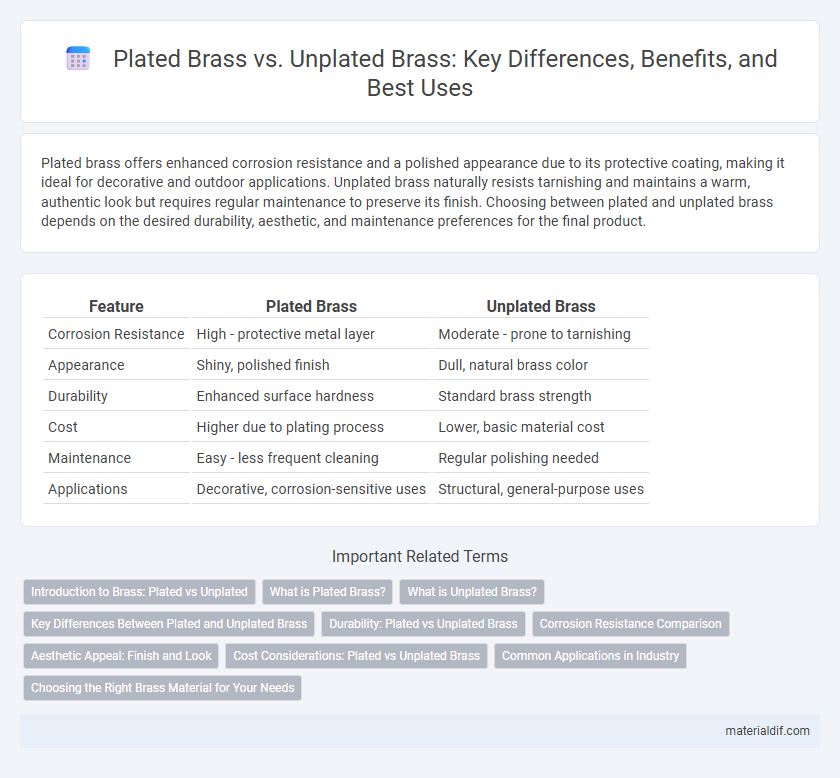

Plated brass offers enhanced corrosion resistance and a polished appearance due to its protective coating, making it ideal for decorative and outdoor applications. Unplated brass naturally resists tarnishing and maintains a warm, authentic look but requires regular maintenance to preserve its finish. Choosing between plated and unplated brass depends on the desired durability, aesthetic, and maintenance preferences for the final product.

Table of Comparison

| Feature | Plated Brass | Unplated Brass |

|---|---|---|

| Corrosion Resistance | High - protective metal layer | Moderate - prone to tarnishing |

| Appearance | Shiny, polished finish | Dull, natural brass color |

| Durability | Enhanced surface hardness | Standard brass strength |

| Cost | Higher due to plating process | Lower, basic material cost |

| Maintenance | Easy - less frequent cleaning | Regular polishing needed |

| Applications | Decorative, corrosion-sensitive uses | Structural, general-purpose uses |

Introduction to Brass: Plated vs Unplated

Brass, an alloy primarily composed of copper and zinc, is widely used in manufacturing due to its corrosion resistance and aesthetic appeal. Plated brass features a thin layer of metal, such as nickel or chromium, applied to enhance durability and prevent tarnishing, while unplated brass maintains its natural surface finish. The choice between plated and unplated brass depends on the desired look, environmental exposure, and specific application requirements.

What is Plated Brass?

Plated brass is brass alloy coated with a thin layer of metal such as nickel, chrome, or gold to enhance appearance and corrosion resistance. This plating process improves durability and provides a smooth, polished finish compared to unplated brass. Common applications include decorative hardware, musical instruments, and plumbing fixtures where aesthetic appeal and protection are essential.

What is Unplated Brass?

Unplated brass is an alloy primarily composed of copper and zinc that remains in its natural state without any surface coating or plating. This type of brass offers excellent corrosion resistance, machinability, and a distinctive golden-yellow appearance valued in decorative and industrial applications. Unlike plated brass, unplated brass does not have an added protective or aesthetic layer, making it more prone to tarnishing over time but easier to solder and form.

Key Differences Between Plated and Unplated Brass

Plated brass features a thin layer of a different metal, such as nickel, chrome, or gold, enhancing corrosion resistance and aesthetic appeal, while unplated brass retains its natural finish and is more prone to tarnishing over time. Key differences include durability, maintenance, and cost, with plated brass requiring less upkeep and typically commanding a higher price due to its protective coating. Unplated brass is favored for its natural look and ease of machining, but plated brass is preferred in applications demanding longevity and enhanced visual qualities.

Durability: Plated vs Unplated Brass

Plated brass offers enhanced durability by providing a protective layer that resists corrosion, tarnishing, and wear, extending the lifespan of the material in harsh environments. Unplated brass, while naturally corrosion-resistant due to its copper and zinc alloy composition, is more susceptible to oxidation and surface damage over time. The choice between plated and unplated brass depends on the specific application and exposure conditions, with plated brass being ideal for high-traffic or moisture-prone settings.

Corrosion Resistance Comparison

Plated brass offers enhanced corrosion resistance due to its protective outer layer, which guards against oxidation and environmental damage. Unplated brass, while naturally corrosion-resistant because of its copper-zinc alloy composition, is more susceptible to tarnishing and surface degradation over time. Choosing plated brass is ideal for applications exposed to harsh conditions, whereas unplated brass suits indoor or low-exposure environments.

Aesthetic Appeal: Finish and Look

Plated brass offers a polished, reflective finish that enhances durability and resists tarnishing, making it ideal for decorative applications requiring a sleek, shiny appearance. Unplated brass displays a warm, natural golden hue that develops a unique patina over time, adding character and a vintage aesthetic. The choice between plated and unplated brass significantly impacts the overall visual appeal, balancing maintenance needs with desired style and finish longevity.

Cost Considerations: Plated vs Unplated Brass

Plated brass generally incurs higher costs due to additional processing steps such as electroplating, which enhances corrosion resistance and aesthetic appeal but increases material and labor expenses. Unplated brass offers a more budget-friendly option with lower manufacturing costs but may require more frequent maintenance or replacement in environments prone to tarnishing or wear. Evaluating the long-term cost implications involves balancing upfront plating expenses against potential savings from durability and reduced upkeep.

Common Applications in Industry

Plated brass offers enhanced corrosion resistance and an attractive finish, making it ideal for decorative hardware, electrical connectors, and plumbing fixtures where durability and aesthetics are critical. Unplated brass, prized for its excellent machinability and thermal conductivity, is commonly used in mechanical components, valves, and musical instruments requiring reliable performance without additional coatings. Both variants serve distinct roles across industries, with plating choice often determined by environmental exposure and functional requirements.

Choosing the Right Brass Material for Your Needs

Plated brass offers enhanced corrosion resistance and aesthetic appeal, making it ideal for decorative fixtures and outdoor applications, while unplated brass provides superior machinability and natural antimicrobial properties suited for industrial components and plumbing. Selecting the right brass depends on factors like environmental exposure, durability requirements, and desired finish longevity. Understanding these distinctions ensures optimal performance and cost-efficiency in your project.

Plated Brass vs Unplated Brass Infographic

materialdif.com

materialdif.com