Brass alloys combine copper with elements like zinc, tin, or aluminum to enhance strength, corrosion resistance, and machinability compared to pure brass, which is primarily a copper-zinc mixture. Pure brass offers excellent electrical conductivity and a bright, yellow-gold appearance but tends to be softer and less durable than its alloyed counterparts. Choosing between brass alloys and pure brass depends on the specific application needs, balancing aesthetics, mechanical properties, and environmental resistance.

Table of Comparison

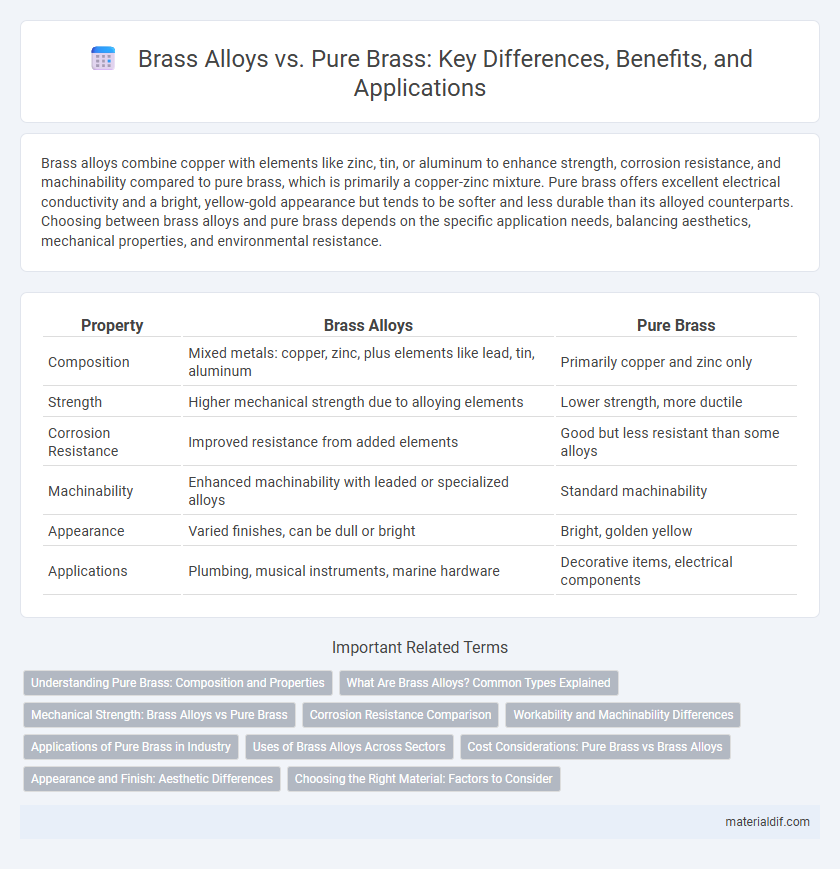

| Property | Brass Alloys | Pure Brass |

|---|---|---|

| Composition | Mixed metals: copper, zinc, plus elements like lead, tin, aluminum | Primarily copper and zinc only |

| Strength | Higher mechanical strength due to alloying elements | Lower strength, more ductile |

| Corrosion Resistance | Improved resistance from added elements | Good but less resistant than some alloys |

| Machinability | Enhanced machinability with leaded or specialized alloys | Standard machinability |

| Appearance | Varied finishes, can be dull or bright | Bright, golden yellow |

| Applications | Plumbing, musical instruments, marine hardware | Decorative items, electrical components |

Understanding Pure Brass: Composition and Properties

Pure brass primarily consists of approximately 60-70% copper and 30-40% zinc, creating a balanced alloy known for its excellent machinability and corrosion resistance. Its uniform composition enhances thermal and electrical conductivity compared to brass alloys with additional elements like lead or tin. Understanding pure brass properties is crucial for applications requiring consistent strength, malleability, and durability in plumbing, musical instruments, and decorative hardware.

What Are Brass Alloys? Common Types Explained

Brass alloys are metal mixtures primarily composed of copper and zinc, enhanced with additional elements like lead, tin, or aluminum to improve mechanical properties and corrosion resistance. Common types include alpha brass with less than 35% zinc, favored for cold working; beta brass containing 35-45% zinc, known for high strength and heat workability; and leaded brass, which offers superior machinability due to added lead. These variations provide targeted performance benefits over pure brass, which is typically just copper and zinc, optimizing applications in plumbing, electrical components, and decorative items.

Mechanical Strength: Brass Alloys vs Pure Brass

Brass alloys exhibit enhanced mechanical strength compared to pure brass due to the addition of elements like zinc, tin, and aluminum, which improve hardness and tensile strength. Pure brass, primarily consisting of copper and zinc, offers good corrosion resistance but has lower mechanical durability under stress. The tailored composition of brass alloys makes them ideal for applications requiring higher load-bearing capacity and wear resistance.

Corrosion Resistance Comparison

Brass alloys typically exhibit enhanced corrosion resistance compared to pure brass due to the addition of elements like zinc, tin, and aluminum, which improve durability in harsh environments. Pure brass, primarily composed of copper and zinc, is more prone to dezincification and surface oxidation when exposed to moisture and corrosive agents. The tailored composition of brass alloys effectively mitigates these corrosion issues, making them more suitable for industrial applications requiring prolonged exposure to corrosive conditions.

Workability and Machinability Differences

Brass alloys exhibit enhanced workability and machinability compared to pure brass due to the presence of alloying elements like zinc, which improve strength and reduce brittleness. Pure brass, primarily composed of copper and zinc in nearly equal proportions, tends to be softer and more ductile but may lack the machinability precision offered by specialized alloys. Variations in zinc content and additional elements such as lead or tin in brass alloys optimize the balance between ease of forming and cutting performance during manufacturing processes.

Applications of Pure Brass in Industry

Pure brass, composed primarily of copper and zinc, offers exceptional corrosion resistance and electrical conductivity, making it ideal for electrical components and marine hardware. Its antimicrobial properties and machinability also enable applications in medical instruments and decorative fittings. Industries such as plumbing, electronics, and instrumentation rely heavily on pure brass for durability and precision performance.

Uses of Brass Alloys Across Sectors

Brass alloys, combining copper with zinc and other elements like tin, lead, or aluminum, enhance mechanical properties such as strength, corrosion resistance, and machinability compared to pure brass. These improved characteristics make brass alloys essential in diverse sectors including automotive manufacturing for radiator cores and fittings, electrical engineering for connectors and terminals, and marine industries where durability against seawater corrosion is critical. The versatility of brass alloys extends to musical instruments, plumbing components, and decorative hardware, demonstrating their broad industrial and commercial applications beyond what pure brass alone can achieve.

Cost Considerations: Pure Brass vs Brass Alloys

Brass alloys generally offer more cost-effective solutions compared to pure brass due to the incorporation of other metals like zinc, which reduce material costs without significantly compromising strength or corrosion resistance. Pure brass, composed mainly of copper and zinc in precise ratios, tends to have higher material expenses owing to its greater copper content and manufacturing demands. For applications requiring budget-friendly materials with adequate performance, brass alloys provide a balanced option, while pure brass suits specialized uses where material purity justifies the premium cost.

Appearance and Finish: Aesthetic Differences

Brass alloys exhibit a wider range of colors and finishes compared to pure brass, ranging from reddish to yellowish hues depending on the copper-to-zinc ratio and additional metals like tin or lead. Pure brass typically has a bright yellow appearance with a smooth, high-gloss finish, while alloyed brass offers more matte or textured finishes due to varied compositions and machining processes. These aesthetic differences influence applications where visual appeal and surface treatment are critical, such as architectural hardware and decorative fittings.

Choosing the Right Material: Factors to Consider

When choosing between brass alloys and pure brass, consider factors such as strength, corrosion resistance, and machinability, as brass alloys typically offer enhanced mechanical properties due to added elements like zinc, tin, or aluminum. Pure brass, composed mainly of copper and zinc, provides excellent electrical conductivity and workability but may lack the durability needed for heavy-duty applications. Cost, intended use, and environmental conditions also play crucial roles in selecting the right brass material for optimal performance and longevity.

Brass Alloys vs Pure Brass Infographic

materialdif.com

materialdif.com