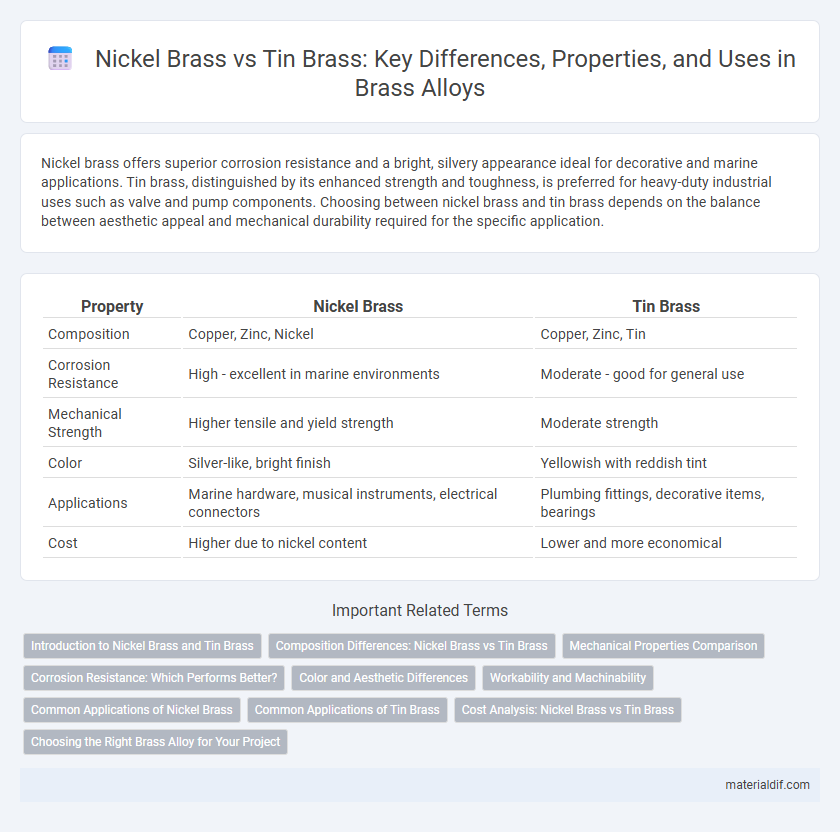

Nickel brass offers superior corrosion resistance and a bright, silvery appearance ideal for decorative and marine applications. Tin brass, distinguished by its enhanced strength and toughness, is preferred for heavy-duty industrial uses such as valve and pump components. Choosing between nickel brass and tin brass depends on the balance between aesthetic appeal and mechanical durability required for the specific application.

Table of Comparison

| Property | Nickel Brass | Tin Brass |

|---|---|---|

| Composition | Copper, Zinc, Nickel | Copper, Zinc, Tin |

| Corrosion Resistance | High - excellent in marine environments | Moderate - good for general use |

| Mechanical Strength | Higher tensile and yield strength | Moderate strength |

| Color | Silver-like, bright finish | Yellowish with reddish tint |

| Applications | Marine hardware, musical instruments, electrical connectors | Plumbing fittings, decorative items, bearings |

| Cost | Higher due to nickel content | Lower and more economical |

Introduction to Nickel Brass and Tin Brass

Nickel brass is an alloy composed primarily of copper, nickel, and zinc, known for its superior corrosion resistance and strength compared to traditional brass. Tin brass, containing copper, zinc, and tin, offers enhanced wear resistance and improved machinability, making it suitable for applications exposed to harsher environments. Both alloys serve distinct industrial purposes, with nickel brass excelling in marine and chemical settings while tin brass is preferred in mechanical components requiring durability.

Composition Differences: Nickel Brass vs Tin Brass

Nickel brass typically contains approximately 60% copper, 30% zinc, and 10% nickel, which enhances its corrosion resistance and mechanical strength. Tin brass usually comprises around 85% copper, 5% tin, and 10% zinc, offering improved machinability and wear resistance. These composition differences result in distinct physical properties, making nickel brass ideal for marine applications and tin brass suitable for components requiring high durability and resistance to dezincification.

Mechanical Properties Comparison

Nickel brass demonstrates superior tensile strength and corrosion resistance compared to tin brass, making it ideal for applications requiring durability under stress. Tin brass offers better machinability and enhanced wear resistance due to the presence of tin, which improves surface hardness. Both alloys exhibit good thermal conductivity, but nickel brass typically maintains higher mechanical integrity at elevated temperatures.

Corrosion Resistance: Which Performs Better?

Nickel brass exhibits superior corrosion resistance compared to tin brass due to the presence of nickel, which enhances its ability to withstand harsh environments and oxidizing agents. Tin brass offers moderate corrosion resistance but tends to tarnish more quickly when exposed to moisture and chemicals. For applications requiring prolonged durability and minimal maintenance in corrosive settings, nickel brass is the preferred choice.

Color and Aesthetic Differences

Nickel brass exhibits a silvery-gold hue with a shiny, polished surface ideal for modern, high-end design aesthetics, while tin brass features a warmer, muted yellow tone that offers a vintage, antique look favored in traditional decor. The presence of nickel in nickel brass enhances its brightness and corrosion resistance, making it a popular choice for decorative hardware and musical instruments. Tin brass's subdued color and slightly matte finish provide a subtle elegance suitable for classic jewelry and ornamental applications.

Workability and Machinability

Nickel brass offers superior machinability due to its uniform grain structure and higher tensile strength, making it ideal for precision components requiring tight tolerances. Tin brass provides excellent workability with enhanced resistance to corrosion and wear, often preferred for stamped or formed parts in marine and industrial applications. Both alloys maintain good thermal conductivity and durability, but nickel brass excels in machining processes while tin brass is favored for complex shaping tasks.

Common Applications of Nickel Brass

Nickel brass, an alloy composed primarily of copper, nickel, and zinc, is widely used in marine hardware, musical instruments, and electrical components due to its excellent corrosion resistance and high strength. Its durability and ability to withstand harsh environments make it ideal for applications such as valve components, plumbing fittings, and shipbuilding. Compared to tin brass, which is favored for its machinability and solderability, nickel brass excels in structural applications requiring robustness and longevity.

Common Applications of Tin Brass

Tin brass, an alloy primarily composed of copper, zinc, and a small percentage of tin, is widely utilized in plumbing fixtures, marine hardware, and electrical connectors due to its superior corrosion resistance and mechanical strength compared to nickel brass. Its enhanced durability makes it ideal for applications exposed to harsh environmental conditions, such as valves and pumps in seawater systems. These properties ensure that tin brass delivers longevity and reliability in both industrial and decorative applications.

Cost Analysis: Nickel Brass vs Tin Brass

Nickel brass generally incurs higher costs due to the inclusion of nickel, which enhances corrosion resistance and mechanical strength but raises raw material expenses. Tin brass offers a more economical alternative with moderate corrosion resistance, making it suitable for budget-sensitive applications. Cost analysis favors tin brass when prioritizing affordability without compromising essential durability.

Choosing the Right Brass Alloy for Your Project

Nickel brass offers superior corrosion resistance and enhanced mechanical strength, making it ideal for marine and industrial applications where durability is critical. Tin brass provides excellent machinability and improved wear resistance, suitable for precision components and decorative purposes. Selecting between nickel brass and tin brass depends on specific project requirements such as environmental exposure, mechanical stress, and aesthetic demands.

Nickel Brass vs Tin Brass Infographic

materialdif.com

materialdif.com