Rolled brass offers superior strength and uniformity due to the metal being passed through rollers, which compresses and elongates the material for enhanced structural integrity. Stamped brass, created by pressing the metal into shapes with dies, allows for faster production and intricate detailing but may result in weaker components prone to deformation. Choosing between rolled and stamped brass depends on the specific application requirements, balancing durability with design complexity.

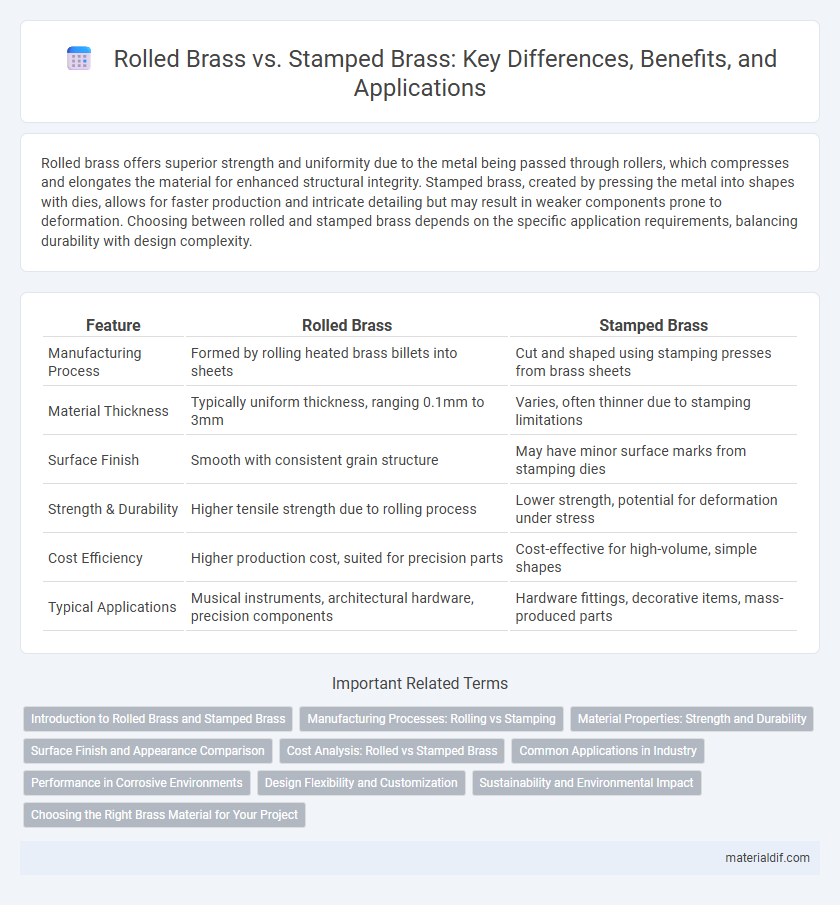

Table of Comparison

| Feature | Rolled Brass | Stamped Brass |

|---|---|---|

| Manufacturing Process | Formed by rolling heated brass billets into sheets | Cut and shaped using stamping presses from brass sheets |

| Material Thickness | Typically uniform thickness, ranging 0.1mm to 3mm | Varies, often thinner due to stamping limitations |

| Surface Finish | Smooth with consistent grain structure | May have minor surface marks from stamping dies |

| Strength & Durability | Higher tensile strength due to rolling process | Lower strength, potential for deformation under stress |

| Cost Efficiency | Higher production cost, suited for precision parts | Cost-effective for high-volume, simple shapes |

| Typical Applications | Musical instruments, architectural hardware, precision components | Hardware fittings, decorative items, mass-produced parts |

Introduction to Rolled Brass and Stamped Brass

Rolled brass is produced by passing brass sheets through rollers to achieve uniform thickness and enhanced strength, making it ideal for structural applications requiring durability. Stamped brass involves pressing brass sheets into desired shapes using dies, allowing for intricate designs and high-volume production with precise detailing. Both methods utilize different manufacturing techniques to optimize the material properties of brass for diverse industrial and decorative uses.

Manufacturing Processes: Rolling vs Stamping

Rolled brass is produced by passing brass slabs through heavy rollers that compress and elongate the metal, enhancing its strength and uniformity. Stamped brass involves cutting shapes from brass sheets using high-pressure dies, allowing complex patterns but potentially weaker structural integrity. The rolling process yields thicker, more durable brass with consistent grain flow, while stamping offers precision and speed for intricate designs but may introduce stress points.

Material Properties: Strength and Durability

Rolled brass exhibits superior strength and durability due to its uniform grain structure achieved through the rolling process, enhancing resistance to wear and deformation. Stamped brass, while cost-effective, often has reduced strength because the stamping process can create internal stresses and microscopic cracks, negatively impacting its long-term durability. This makes rolled brass the preferred choice for applications requiring high mechanical performance and longevity.

Surface Finish and Appearance Comparison

Rolled brass features a smoother, more uniform surface finish due to its manufacturing process, resulting in a polished and refined appearance ideal for decorative applications. Stamped brass often exhibits slight surface irregularities and a less consistent texture, which can affect its visual appeal but offers more intricate shapes and patterns. Surface finish quality directly influences the final look, with rolled brass preferred for a sleek, high-end finish, while stamped brass provides versatility in design at a potentially lower aesthetic standard.

Cost Analysis: Rolled vs Stamped Brass

Rolled brass typically incurs higher production costs due to the intensive manufacturing process that involves heating and pressing metal sheets, resulting in superior strength and uniformity. Stamped brass, created by cutting shapes from thin sheets using dies, offers cost-effective mass production with faster turnaround times but may compromise on structural integrity. Evaluating cost analysis between rolled and stamped brass depends largely on volume, design complexity, and application durability requirements.

Common Applications in Industry

Rolled brass is widely used in applications requiring high durability and precision such as electrical components, musical instruments, and architectural hardware because of its uniform thickness and enhanced mechanical properties. Stamped brass is commonly employed in mass production industries for creating intricate shapes in automotive parts, decorative items, and housewares due to its cost efficiency and rapid manufacturing process. Both materials serve critical roles in industrial manufacturing, with rolled brass favored for performance-critical components and stamped brass preferred for detailed, high-volume parts.

Performance in Corrosive Environments

Rolled brass exhibits superior performance in corrosive environments due to its denser grain structure and enhanced mechanical properties, resulting from the rolling process. Stamped brass, while easier to mass-produce, often contains micro-stresses and less uniformity, making it more susceptible to corrosion and wear over time. For applications demanding durability in harsh or marine conditions, rolled brass offers greater resistance and longevity.

Design Flexibility and Customization

Rolled brass offers superior design flexibility due to its uniform thickness and smooth surface, allowing intricate detailing and precise cuts in custom applications. Stamped brass, while faster to produce, is limited by the stamping die and thickness variations, restricting complex designs and fine customization. For projects requiring detailed patterns and tailored shapes, rolled brass is the preferred choice for enhanced customization options.

Sustainability and Environmental Impact

Rolled brass offers enhanced sustainability by utilizing less energy during production compared to stamped brass, which requires more intensive metal deformation processes. Stamped brass often generates higher material waste due to trimming and rejection rates, whereas rolled brass benefits from more efficient material usage and recyclability. The environmental impact of rolled brass is generally lower, making it a preferable option for eco-conscious manufacturing and product design.

Choosing the Right Brass Material for Your Project

Rolled brass offers superior strength and durability due to its dense grain structure, making it ideal for applications requiring high mechanical performance. Stamped brass provides cost-effective versatility and precision for intricate designs, suited for decorative or lightweight projects. Evaluating project demands on durability, detail, and budget ensures optimal selection between rolled and stamped brass materials.

Rolled Brass vs Stamped Brass Infographic

materialdif.com

materialdif.com