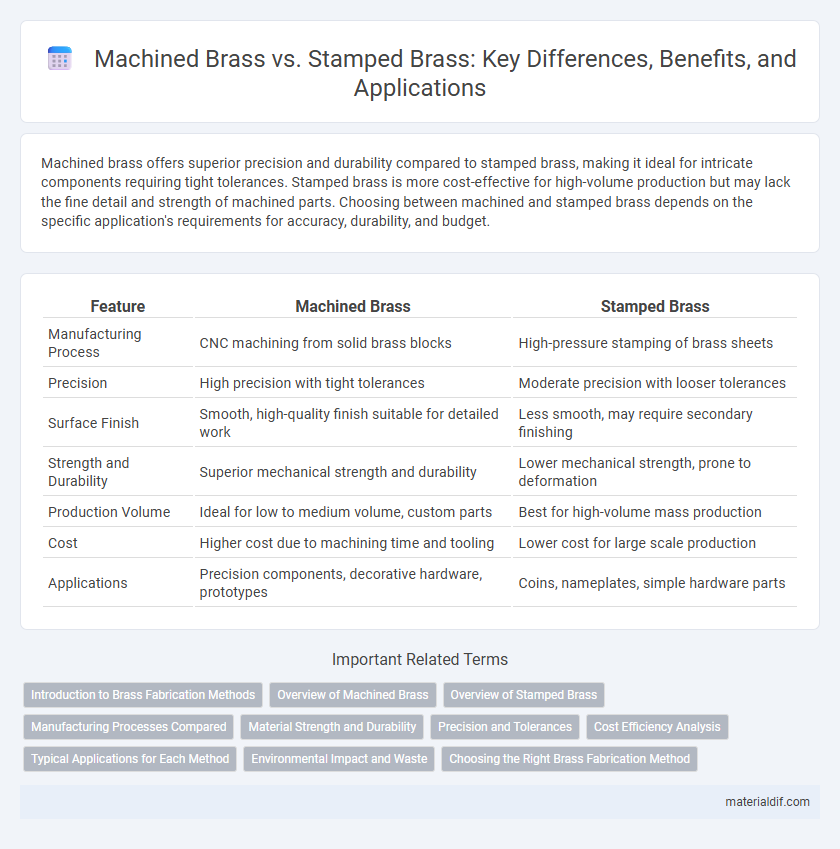

Machined brass offers superior precision and durability compared to stamped brass, making it ideal for intricate components requiring tight tolerances. Stamped brass is more cost-effective for high-volume production but may lack the fine detail and strength of machined parts. Choosing between machined and stamped brass depends on the specific application's requirements for accuracy, durability, and budget.

Table of Comparison

| Feature | Machined Brass | Stamped Brass |

|---|---|---|

| Manufacturing Process | CNC machining from solid brass blocks | High-pressure stamping of brass sheets |

| Precision | High precision with tight tolerances | Moderate precision with looser tolerances |

| Surface Finish | Smooth, high-quality finish suitable for detailed work | Less smooth, may require secondary finishing |

| Strength and Durability | Superior mechanical strength and durability | Lower mechanical strength, prone to deformation |

| Production Volume | Ideal for low to medium volume, custom parts | Best for high-volume mass production |

| Cost | Higher cost due to machining time and tooling | Lower cost for large scale production |

| Applications | Precision components, decorative hardware, prototypes | Coins, nameplates, simple hardware parts |

Introduction to Brass Fabrication Methods

Machined brass involves precise shaping and cutting using CNC machines or lathes, offering high dimensional accuracy and smooth finishes essential for complex components. Stamped brass utilizes high-pressure presses to form sheets into specific shapes, providing cost-effective and rapid production ideal for high-volume manufacturing. Both methods are pivotal in brass fabrication, with machining suited for custom or intricate parts and stamping optimized for repetitive, large-scale applications.

Overview of Machined Brass

Machined brass offers precise dimensional accuracy and high strength due to its manufacturing process, which involves cutting and shaping solid brass billets. This method allows for intricate designs, tighter tolerances, and superior surface finishes compared to stamped brass. Commonly used in applications requiring durability and fine detail, machined brass is ideal for custom components and high-performance hardware.

Overview of Stamped Brass

Stamped brass offers a cost-effective manufacturing process ideal for producing large quantities of uniform components with consistent thickness. This method employs high-pressure presses to shape brass sheets quickly, enabling intricate designs and fine details with minimal material waste. Commonly used in decorative trims, electrical connectors, and musical instruments, stamped brass balances durability and aesthetic appeal for various industrial applications.

Manufacturing Processes Compared

Machined brass involves precision cutting and shaping from solid brass billets using CNC machines, ensuring high dimensional accuracy and complex geometries with tight tolerances. Stamped brass is produced by pressing brass sheets into desired shapes using dies, which is faster and more cost-effective for high-volume production but may result in less intricate details and lower structural strength. The choice between machined and stamped brass depends on factors such as design complexity, production volume, and required mechanical properties.

Material Strength and Durability

Machined brass offers superior material strength and durability due to its solid construction and precise manufacturing process, making it ideal for high-stress applications. Stamped brass, while more cost-effective and suitable for mass production, generally exhibits lower strength and is more prone to deformation under heavy loads. Choosing machined brass ensures longer-lasting performance and resistance to wear compared to stamped brass components.

Precision and Tolerances

Machined brass offers superior precision and tighter tolerances compared to stamped brass due to its controlled material removal process and advanced CNC machining techniques. Stamped brass typically exhibits looser tolerances because of the deformation involved in the stamping process, which can introduce variability in dimensions. For applications requiring exact fits and intricate detail, machined brass provides a reliable solution with consistent dimensional accuracy.

Cost Efficiency Analysis

Machined brass offers higher precision and durability due to its solid material cutting process, but it incurs greater manufacturing costs and longer production times compared to stamped brass. Stamped brass, produced through a rapid pressing method, significantly reduces labor and tooling expenses, making it more cost-efficient for high-volume, less complex parts. Evaluating the cost efficiency depends on the application's precision requirements and production scale, with stamped brass favored for mass production and machined brass suited for specialized, intricate components.

Typical Applications for Each Method

Machined brass is commonly used in precision components such as valves, gears, and custom fittings where tight tolerances and durability are critical. Stamped brass is preferred for high-volume production of flat parts like electrical connectors, decorative trims, and nameplates due to its cost-effectiveness and rapid manufacturing process. Each method suits distinct industrial needs, balancing quality and production efficiency in brass part fabrication.

Environmental Impact and Waste

Machined brass produces significantly less environmental waste compared to stamped brass, as the precise cutting process reduces scrap material and allows for easier recycling of metal shavings. Stamped brass often generates excess scrap due to the high-pressure cutting and forming methods, leading to increased resource consumption and landfill waste. Choosing machined brass supports sustainable manufacturing practices by minimizing waste and promoting efficient use of raw materials.

Choosing the Right Brass Fabrication Method

Machined brass offers precise dimensional accuracy and a smooth finish, making it ideal for applications requiring tight tolerances and intricate details. Stamped brass provides cost-effective high-volume production with consistent shapes but may have limited complexity and surface quality compared to machining. Selecting the right fabrication method depends on balancing factors like production volume, design complexity, surface finish requirements, and budget constraints.

Machined Brass vs Stamped Brass Infographic

materialdif.com

materialdif.com