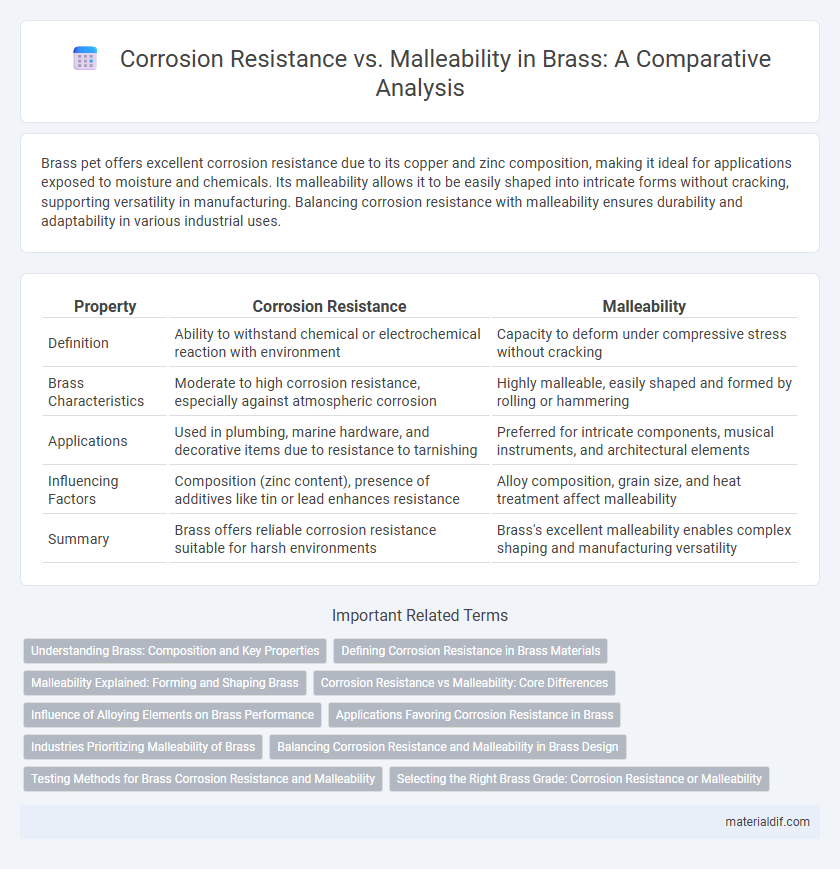

Brass pet offers excellent corrosion resistance due to its copper and zinc composition, making it ideal for applications exposed to moisture and chemicals. Its malleability allows it to be easily shaped into intricate forms without cracking, supporting versatility in manufacturing. Balancing corrosion resistance with malleability ensures durability and adaptability in various industrial uses.

Table of Comparison

| Property | Corrosion Resistance | Malleability |

|---|---|---|

| Definition | Ability to withstand chemical or electrochemical reaction with environment | Capacity to deform under compressive stress without cracking |

| Brass Characteristics | Moderate to high corrosion resistance, especially against atmospheric corrosion | Highly malleable, easily shaped and formed by rolling or hammering |

| Applications | Used in plumbing, marine hardware, and decorative items due to resistance to tarnishing | Preferred for intricate components, musical instruments, and architectural elements |

| Influencing Factors | Composition (zinc content), presence of additives like tin or lead enhances resistance | Alloy composition, grain size, and heat treatment affect malleability |

| Summary | Brass offers reliable corrosion resistance suitable for harsh environments | Brass's excellent malleability enables complex shaping and manufacturing versatility |

Understanding Brass: Composition and Key Properties

Brass, primarily composed of copper and zinc, exhibits excellent corrosion resistance due to the protective oxide layer formed by copper. Its malleability varies with zinc content; higher zinc percentages increase strength but reduce ductility, making it less malleable. Understanding the balance between corrosion resistance and malleability in brass is crucial for selecting appropriate alloys in applications like plumbing, musical instruments, and decorative hardware.

Defining Corrosion Resistance in Brass Materials

Corrosion resistance in brass materials refers to the alloy's ability to withstand degradation caused by environmental factors such as moisture, chemicals, and oxidation. This property is influenced by the percentage of copper and zinc, as well as the presence of elements like tin or lead, which enhance the alloy's durability against tarnishing and rust. High corrosion resistance in brass ensures longevity and maintains structural integrity in applications exposed to harsh conditions.

Malleability Explained: Forming and Shaping Brass

Brass exhibits excellent malleability, allowing it to be easily formed and shaped into intricate designs without cracking or breaking. This characteristic is due to its copper and zinc composition, which provides a balance between softness and strength, making it ideal for applications such as decorative fittings, musical instruments, and precision components. While brass also offers good corrosion resistance, its malleability is particularly valued in manufacturing processes requiring detailed and precise metalworking.

Corrosion Resistance vs Malleability: Core Differences

Brass exhibits notable corrosion resistance due to its copper and zinc composition, making it ideal for marine and plumbing applications where exposure to moisture is frequent. Its malleability allows for easy shaping and forming, essential in manufacturing decorative items and intricate components. The core difference lies in the trade-off: higher zinc content enhances malleability but can reduce corrosion resistance, while increased copper improves resistance at the expense of some ductility.

Influence of Alloying Elements on Brass Performance

Brass corrosion resistance improves with higher percentages of zinc and the addition of elements like tin and phosphorus, which enhance durability in marine and industrial environments. Malleability, on the other hand, is increased by reducing zinc content and incorporating lead, allowing easier shaping and machining. The balance of copper, zinc, and minor alloying elements critically determines brass's overall performance in both corrosion resistance and malleability.

Applications Favoring Corrosion Resistance in Brass

Brass alloys with higher corrosion resistance, often achieved through increased copper and zinc content or the addition of elements like tin and nickel, are preferred in marine hardware, plumbing fittings, and electrical connectors where exposure to moisture and chemicals is frequent. These corrosion-resistant brass variants maintain structural integrity and functionality over time, preventing degradation and costly replacements. In contrast, applications demanding ductility and shaping ease might prioritize malleability over corrosion resistance, but environments involving saline water or acidic conditions rely heavily on corrosion-resistant brass formulations.

Industries Prioritizing Malleability of Brass

Industries such as automotive manufacturing, musical instrument production, and decorative hardware prioritize the malleability of brass to shape complex components with precision while maintaining durability. The ability to easily form and bend brass without cracking is critical for creating intricate designs in door handles, valves, and tubing. These applications favor malleability over corrosion resistance to meet strict design and functional requirements.

Balancing Corrosion Resistance and Malleability in Brass Design

Balancing corrosion resistance and malleability in brass design requires careful alloy composition adjustments, often by varying the copper and zinc ratios, to enhance durability while maintaining workability. Introducing elements like lead or tin can improve machinability and corrosion resistance but may reduce malleability, necessitating trade-offs based on application requirements. Optimizing heat treatment processes further refines brass's microstructure, achieving tailored performance for industrial uses demanding both strength and formability.

Testing Methods for Brass Corrosion Resistance and Malleability

Testing methods for brass corrosion resistance include salt spray tests and electrochemical impedance spectroscopy, which simulate harsh environments and measure degradation rates. Malleability is assessed through tensile strength tests and bend tests to evaluate the alloy's ability to deform without cracking. These evaluation techniques provide critical data to optimize brass compositions for durability and workability in industrial applications.

Selecting the Right Brass Grade: Corrosion Resistance or Malleability

Selecting the right brass grade depends on prioritizing corrosion resistance or malleability based on the application environment. High copper alloys like CDA 260 offer superior corrosion resistance, ideal for marine or chemical exposure, while alloys with higher zinc content, such as CDA 360, provide enhanced malleability suited for intricate machining and forming. Balancing these properties ensures optimal performance, with corrosion-resistant grades preventing degradation and malleable grades facilitating fabrication and shaping processes.

Corrosion Resistance vs Malleability Infographic

materialdif.com

materialdif.com