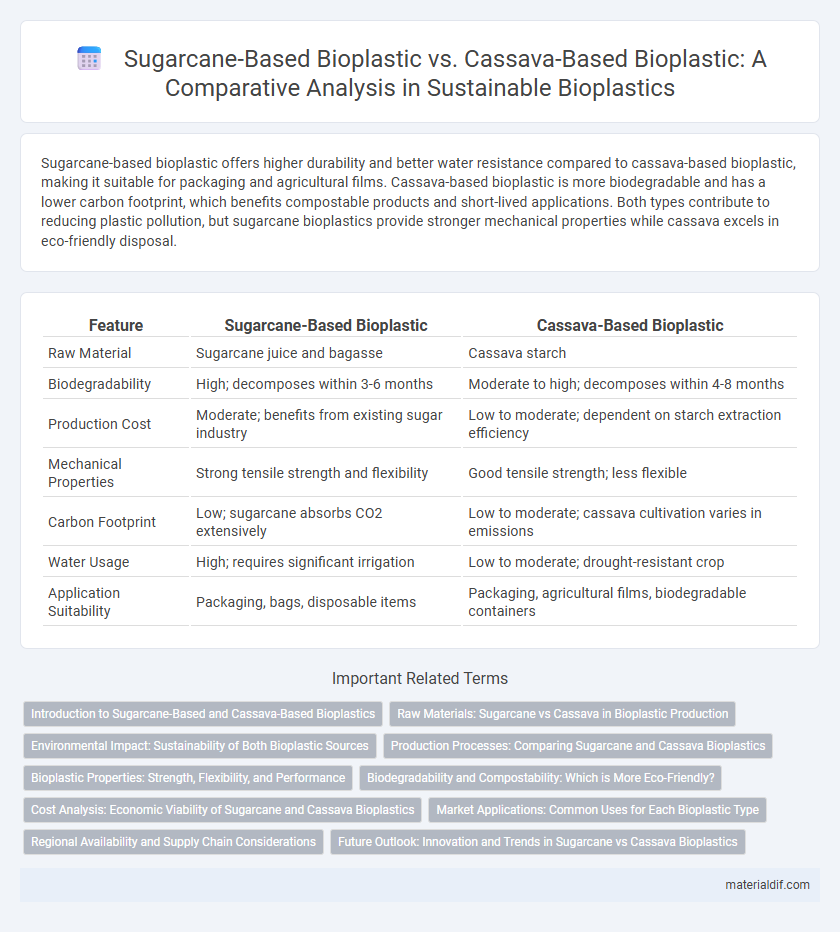

Sugarcane-based bioplastic offers higher durability and better water resistance compared to cassava-based bioplastic, making it suitable for packaging and agricultural films. Cassava-based bioplastic is more biodegradable and has a lower carbon footprint, which benefits compostable products and short-lived applications. Both types contribute to reducing plastic pollution, but sugarcane bioplastics provide stronger mechanical properties while cassava excels in eco-friendly disposal.

Table of Comparison

| Feature | Sugarcane-Based Bioplastic | Cassava-Based Bioplastic |

|---|---|---|

| Raw Material | Sugarcane juice and bagasse | Cassava starch |

| Biodegradability | High; decomposes within 3-6 months | Moderate to high; decomposes within 4-8 months |

| Production Cost | Moderate; benefits from existing sugar industry | Low to moderate; dependent on starch extraction efficiency |

| Mechanical Properties | Strong tensile strength and flexibility | Good tensile strength; less flexible |

| Carbon Footprint | Low; sugarcane absorbs CO2 extensively | Low to moderate; cassava cultivation varies in emissions |

| Water Usage | High; requires significant irrigation | Low to moderate; drought-resistant crop |

| Application Suitability | Packaging, bags, disposable items | Packaging, agricultural films, biodegradable containers |

Introduction to Sugarcane-Based and Cassava-Based Bioplastics

Sugarcane-based bioplastics are derived from the abundant sucrose and cellulose content in sugarcane biomass, offering high biodegradability and reduced carbon footprint compared to conventional plastics. Cassava-based bioplastics utilize starch extracted from cassava roots, known for their excellent film-forming properties and biodegradability in diverse environmental conditions. Both bioplastics are renewable, biodegradable alternatives that contribute to sustainability, though sugarcane-based versions often demonstrate superior mechanical strength and water resistance.

Raw Materials: Sugarcane vs Cassava in Bioplastic Production

Sugarcane-based bioplastic utilizes sucrose-rich sugarcane juice, providing a high yield of fermentable sugars for efficient biopolymer synthesis, making it a sustainable raw material with rapid growth cycles and high biomass output. Cassava-based bioplastic relies on starch extracted from cassava roots, offering a starch-rich alternative that supports biodegradability but involves more intensive processing to convert starch into fermentable sugars. Both raw materials contribute to renewable bioplastic production, with sugarcane favored for higher sugar content and energy efficiency, while cassava offers adaptability in diverse climatic conditions and soil types.

Environmental Impact: Sustainability of Both Bioplastic Sources

Sugarcane-based bioplastics offer high sustainability due to rapid growth cycles and efficient carbon sequestration, significantly reducing greenhouse gas emissions compared to conventional plastics. Cassava-based bioplastics provide a renewable alternative with lower water usage but can raise concerns over land use and competition with food crops. Both materials contribute to decreased environmental impact, yet sugarcane's higher biomass yield and waste utilization enhance its overall ecological advantage in sustainable bioplastic production.

Production Processes: Comparing Sugarcane and Cassava Bioplastics

Sugarcane-based bioplastic production primarily involves extracting sucrose to produce bioethanol, which is then polymerized into polylactic acid (PLA) or polyethylene alternatives, leveraging high sugar content for efficient fermentation. Cassava-based bioplastic production relies on starch extraction, requiring hydrolysis into fermentable sugars before polymer synthesis, often involving more complex enzymatic processes compared to sugarcane. The scalability and yield of sugarcane bioplastics generally surpass cassava due to more straightforward sugar extraction and fermentation, impacting cost-efficiency and environmental footprint.

Bioplastic Properties: Strength, Flexibility, and Performance

Sugarcane-based bioplastic typically exhibits higher tensile strength and durability, making it suitable for applications requiring robust performance, while cassava-based bioplastic offers greater flexibility and biodegradability, ideal for packaging and single-use products. The molecular structure of sugarcane bioplastic provides enhanced resistance to heat and mechanical stress, whereas cassava bioplastic's cellulose content contributes to its elastic properties and faster decomposition rate. Performance-wise, sugarcane bioplastics excel in long-term use and structural applications, contrasting with cassava bioplastics' advantage in eco-friendly, short-term usage scenarios.

Biodegradability and Compostability: Which is More Eco-Friendly?

Sugarcane-based bioplastics exhibit faster biodegradability due to higher cellulose content, breaking down typically within 3 to 6 months under industrial composting conditions. Cassava-based bioplastics, though compostable, tend to degrade more slowly, often requiring longer exposure to maintain their eco-friendly impact. Overall, sugarcane bioplastics demonstrate superior compostability and faster degradation rates, making them a more sustainable choice for reducing plastic pollution.

Cost Analysis: Economic Viability of Sugarcane and Cassava Bioplastics

Sugarcane-based bioplastics often exhibit lower production costs due to higher yield per hectare and established processing infrastructure, enhancing their economic viability. Cassava-based bioplastics, while competitive, face cost challenges from lower starch content and susceptibility to supply fluctuations, impacting price stability. Market analysis shows sugarcane bioplastics benefit from scalable production and government subsidies in key regions, positioning them as a more cost-effective alternative for commercial applications.

Market Applications: Common Uses for Each Bioplastic Type

Sugarcane-based bioplastic is extensively utilized in packaging materials, disposable cutlery, and agricultural films due to its high strength and biodegradability. Cassava-based bioplastic finds common applications in food containers, bags, and biomedical products because of its flexibility and cost-effectiveness. Both types serve sustainable alternatives in the consumer goods and medical sectors, with sugarcane bioplastic favored for durable uses and cassava bioplastic preferred for single-use and flexible items.

Regional Availability and Supply Chain Considerations

Sugarcane-based bioplastic is predominantly produced in regions with vast tropical plantations such as Brazil, India, and Thailand, offering a well-established supply chain due to large-scale sugarcane agriculture and processing infrastructure. Cassava-based bioplastic mainly comes from Southeast Asia and parts of Africa, where cassava is a staple crop with localized farming, leading to more fragmented supply chains and potential seasonal variability. Regional availability directly influences raw material cost, production scalability, and logistical efficiency for bioplastic manufacturers targeting sustainable alternatives to petrochemical plastics.

Future Outlook: Innovation and Trends in Sugarcane vs Cassava Bioplastics

Sugarcane-based bioplastics are advancing with enhanced biodegradability and improved mechanical properties, driven by innovations in fermentation and enzymatic processing techniques. Cassava-based bioplastics show promising trends in cost reduction and scalability, supported by genetic improvements in cassava starch yield and eco-friendly extraction methods. Future developments are likely to focus on hybrid composites combining sugarcane and cassava bioplastics to leverage the high tensile strength of sugarcane and the flexible biodegradability of cassava.

Sugarcane-based bioplastic vs Cassava-based bioplastic Infographic

materialdif.com

materialdif.com