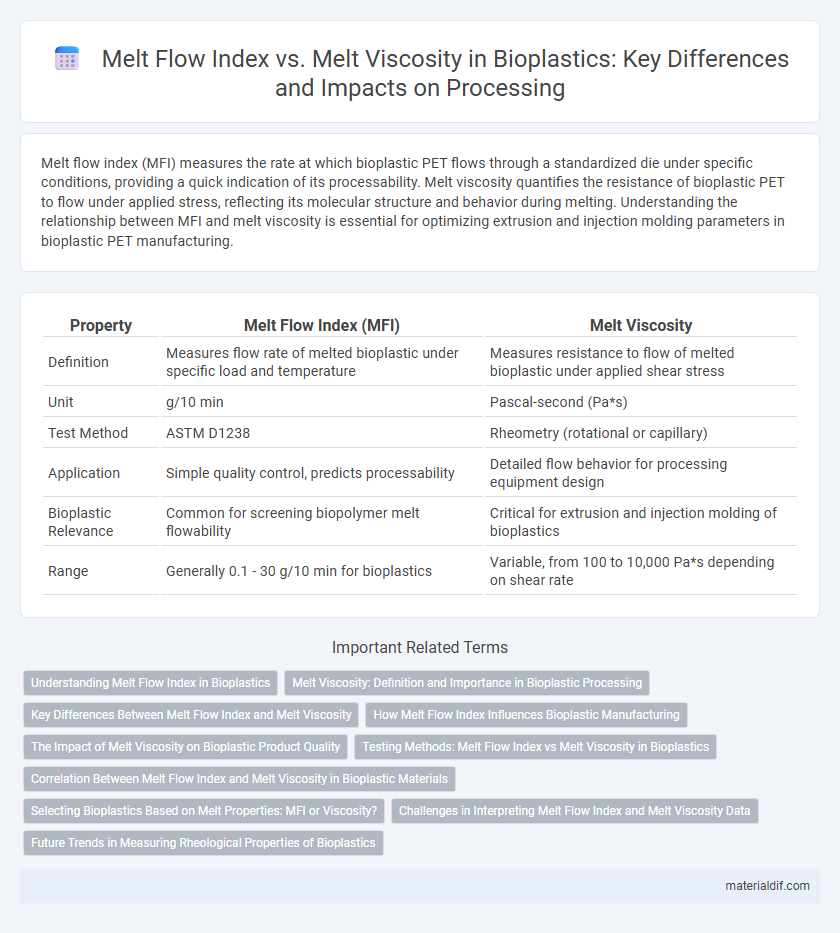

Melt flow index (MFI) measures the rate at which bioplastic PET flows through a standardized die under specific conditions, providing a quick indication of its processability. Melt viscosity quantifies the resistance of bioplastic PET to flow under applied stress, reflecting its molecular structure and behavior during melting. Understanding the relationship between MFI and melt viscosity is essential for optimizing extrusion and injection molding parameters in bioplastic PET manufacturing.

Table of Comparison

| Property | Melt Flow Index (MFI) | Melt Viscosity |

|---|---|---|

| Definition | Measures flow rate of melted bioplastic under specific load and temperature | Measures resistance to flow of melted bioplastic under applied shear stress |

| Unit | g/10 min | Pascal-second (Pa*s) |

| Test Method | ASTM D1238 | Rheometry (rotational or capillary) |

| Application | Simple quality control, predicts processability | Detailed flow behavior for processing equipment design |

| Bioplastic Relevance | Common for screening biopolymer melt flowability | Critical for extrusion and injection molding of bioplastics |

| Range | Generally 0.1 - 30 g/10 min for bioplastics | Variable, from 100 to 10,000 Pa*s depending on shear rate |

Understanding Melt Flow Index in Bioplastics

Melt Flow Index (MFI) measures the ease of flow of melted bioplastic under specific conditions, reflecting its processability and molecular weight distribution. Unlike melt viscosity, which varies with shear rate and temperature, MFI provides a standardized single-point value used to predict how bioplastics will behave during extrusion and injection molding. Understanding MFI helps manufacturers optimize processing parameters for bioplastic materials such as PLA and PBAT, ensuring consistent quality in biodegradable packaging and compostable products.

Melt Viscosity: Definition and Importance in Bioplastic Processing

Melt viscosity measures a bioplastic's resistance to flow under heat and pressure, directly impacting its processability in extrusion, injection molding, and blow molding. High melt viscosity indicates a thicker, slower-flowing melt, which affects the quality and uniformity of the final bioplastic product. Understanding melt viscosity ensures optimal processing conditions, mechanical properties, and consistency in bioplastic manufacturing.

Key Differences Between Melt Flow Index and Melt Viscosity

Melt Flow Index (MFI) measures the rate of polymer flow under a specified load, providing a quick assessment of polymer processability, while Melt Viscosity quantifies the material's resistance to flow under shear at a specific temperature and shear rate. MFI offers a single-point value useful for quality control, whereas melt viscosity yields more detailed rheological behavior, essential for processing simulations and mold design. Understanding these key differences aids in selecting the appropriate testing method for optimizing bioplastic manufacturing processes.

How Melt Flow Index Influences Bioplastic Manufacturing

Melt Flow Index (MFI) is a critical parameter in bioplastic manufacturing that measures the ease of flow of the polymer melt, directly affecting processing conditions like injection molding and extrusion. A higher MFI indicates lower melt viscosity, enabling faster mold filling and finer detailing but may compromise mechanical strength and thermal stability. Controlling MFI helps optimize the balance between manufacturability and product performance in biopolymer applications such as polylactic acid (PLA) and polyhydroxyalkanoates (PHA).

The Impact of Melt Viscosity on Bioplastic Product Quality

Melt viscosity directly influences the flow behavior of bioplastics during processing, affecting their dimensional stability and surface finish. High melt viscosity can lead to poor mold filling and increased internal stresses, resulting in defects such as warping or incomplete formation. Optimizing melt viscosity ensures consistent product quality by improving processability and mechanical properties of bioplastic materials.

Testing Methods: Melt Flow Index vs Melt Viscosity in Bioplastics

Melt Flow Index (MFI) and Melt Viscosity are critical testing methods for evaluating the flow properties of bioplastics under heat. MFI measures the rate of polymer extrusion through a capillary under specified conditions, providing a quick indication of molecular weight and processing behavior. Melt Viscosity testing, typically performed using rheometers, offers a detailed characterization of the material's resistance to flow across a range of shear rates, essential for optimizing processing parameters in bioplastic manufacturing.

Correlation Between Melt Flow Index and Melt Viscosity in Bioplastic Materials

Melt flow index (MFI) measures the ease of flow of bioplastic materials under specific temperature and pressure, providing a quick assessment of processability. Melt viscosity reflects the material's resistance to flow during melting, capturing more detailed rheological behavior critical for extrusion and molding processes. A strong inverse correlation exists between MFI and melt viscosity in bioplastics, where higher MFI values correspond to lower melt viscosity, indicating better flow characteristics essential for optimizing manufacturing parameters.

Selecting Bioplastics Based on Melt Properties: MFI or Viscosity?

Selecting bioplastics based on melt flow index (MFI) or melt viscosity depends on the specific processing requirements and end-use applications. MFI measures the ease of flow of the molten polymer under specific conditions, indicating processability in injection molding, while melt viscosity provides a detailed view of the polymer's resistance to flow under varying shear rates, crucial for extrusion and film blowing. Understanding both parameters helps optimize processing parameters, ensuring the chosen bioplastic performs effectively in the desired manufacturing method and final product performance.

Challenges in Interpreting Melt Flow Index and Melt Viscosity Data

Challenges in interpreting melt flow index (MFI) and melt viscosity data in bioplastics arise from their sensitivity to temperature, shear rate, and molecular weight distribution, which can cause significant variability in results. MFI provides a simplified measure of flow under specific conditions but lacks the ability to fully characterize the complex rheological behavior exhibited by biopolymers. Accurate assessment requires integrating both MFI and melt viscosity data with a thorough understanding of processing parameters to predict material performance effectively.

Future Trends in Measuring Rheological Properties of Bioplastics

Future trends in measuring rheological properties of bioplastics emphasize advanced techniques that provide real-time data on melt flow index (MFI) and melt viscosity under diverse processing conditions. Innovations such as microfluidic rheometry and in-line sensors enable more accurate monitoring of biopolymer behavior, enhancing process control and material consistency. These developments support the optimization of bioplastic formulations, driving improvements in sustainability and performance for next-generation applications.

Melt flow index vs Melt viscosity Infographic

materialdif.com

materialdif.com