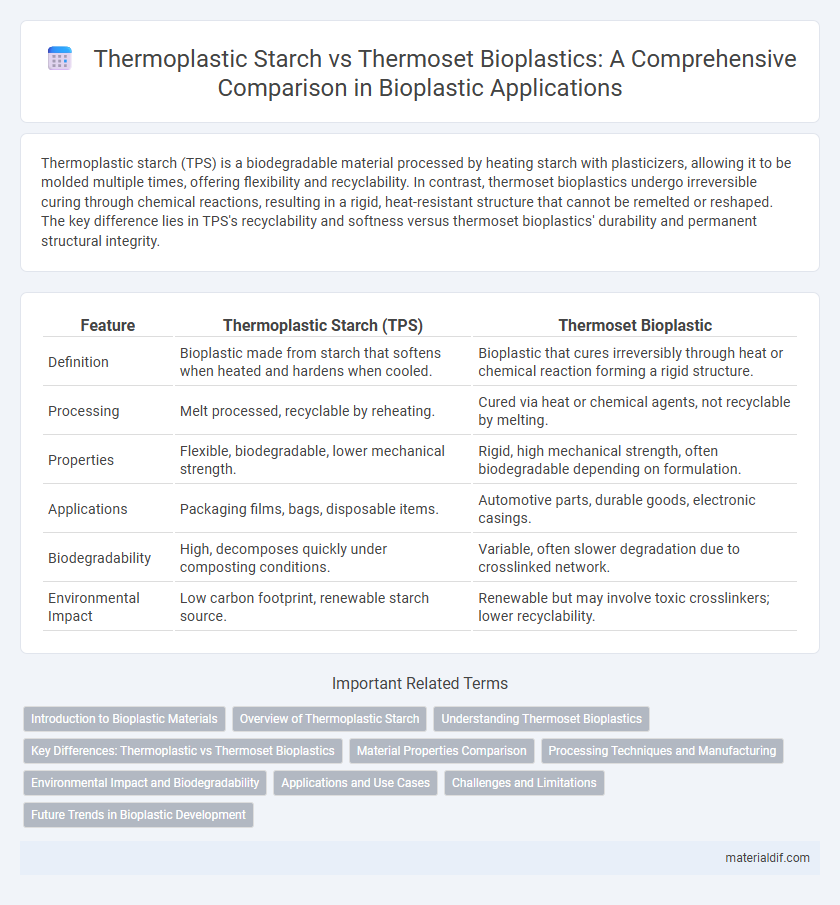

Thermoplastic starch (TPS) is a biodegradable material processed by heating starch with plasticizers, allowing it to be molded multiple times, offering flexibility and recyclability. In contrast, thermoset bioplastics undergo irreversible curing through chemical reactions, resulting in a rigid, heat-resistant structure that cannot be remelted or reshaped. The key difference lies in TPS's recyclability and softness versus thermoset bioplastics' durability and permanent structural integrity.

Table of Comparison

| Feature | Thermoplastic Starch (TPS) | Thermoset Bioplastic |

|---|---|---|

| Definition | Bioplastic made from starch that softens when heated and hardens when cooled. | Bioplastic that cures irreversibly through heat or chemical reaction forming a rigid structure. |

| Processing | Melt processed, recyclable by reheating. | Cured via heat or chemical agents, not recyclable by melting. |

| Properties | Flexible, biodegradable, lower mechanical strength. | Rigid, high mechanical strength, often biodegradable depending on formulation. |

| Applications | Packaging films, bags, disposable items. | Automotive parts, durable goods, electronic casings. |

| Biodegradability | High, decomposes quickly under composting conditions. | Variable, often slower degradation due to crosslinked network. |

| Environmental Impact | Low carbon footprint, renewable starch source. | Renewable but may involve toxic crosslinkers; lower recyclability. |

Introduction to Bioplastic Materials

Thermoplastic starch (TPS) is a biodegradable bioplastic derived from natural starch that softens when heated and hardens upon cooling, allowing it to be reshaped multiple times. Thermoset bioplastics, in contrast, form irreversible cross-linked structures during curing, providing enhanced mechanical strength and thermal stability but losing their ability to be remolded. These fundamental differences influence their applications, with TPS favored for flexible packaging and thermoset bioplastics used in durable goods and composites.

Overview of Thermoplastic Starch

Thermoplastic starch (TPS) is a biodegradable material derived from natural starches such as corn, potato, and tapioca, widely used for its renewable and eco-friendly attributes. Unlike thermoset bioplastics, TPS softens upon heating and can be repeatedly molded, making it versatile for packaging, agricultural films, and disposable items. Its starch-based composition offers sustainable alternatives with lower carbon footprints and improved compostability compared to conventional plastics.

Understanding Thermoset Bioplastics

Thermoset bioplastics undergo irreversible curing processes that create strong, cross-linked polymer networks, resulting in high durability and heat resistance compared to thermoplastic starch, which softens upon heating and can be reshaped. These materials are commonly derived from renewable resources such as plant-based resins and natural fibers, making them sustainable alternatives to conventional plastics. Their chemical stability and structural integrity make thermoset bioplastics ideal for applications requiring long-term performance and environmental resistance.

Key Differences: Thermoplastic vs Thermoset Bioplastics

Thermoplastic starch bioplastics melt when heated, allowing them to be reshaped and recycled multiple times, whereas thermoset bioplastics undergo irreversible curing, resulting in a rigid, heat-resistant structure that cannot be remolded. Thermoplastic starch offers flexibility and ease of processing, making it ideal for packaging applications, while thermoset bioplastics provide superior mechanical strength and chemical resistance suited for durable goods. The distinct molecular arrangement in thermoplastics consists of linear or branched polymers, unlike the cross-linked network in thermosets, which defines their thermal and mechanical behaviors.

Material Properties Comparison

Thermoplastic starch exhibits high flexibility and easy processability due to its ability to soften upon heating and solidify when cooled, making it suitable for applications requiring moldability and recyclability. In contrast, thermoset bioplastics form irreversible cross-linked networks after curing, leading to superior mechanical strength, heat resistance, and dimensional stability but limited recyclability. The choice between thermoplastic starch and thermoset bioplastics depends on specific requirements for biodegradability, thermal performance, and mechanical durability in sustainable packaging and product design.

Processing Techniques and Manufacturing

Thermoplastic starch (TPS) is processed through melt extrusion or injection molding, where the material softens upon heating and solidifies upon cooling, allowing easy reshaping and recycling, making it suitable for packaging applications. Thermoset bioplastics undergo irreversible chemical crosslinking during curing processes such as compression molding or resin infusion, resulting in a rigid, heat-resistant structure ideal for automotive and construction uses. Manufacturing TPS typically involves blending starch with plasticizers like glycerol to improve flexibility, while thermoset bioplastics require precise control of curing time and temperature to achieve desired mechanical properties.

Environmental Impact and Biodegradability

Thermoplastic starch (TPS) exhibits a lower environmental impact due to its biodegradability and renewability, breaking down efficiently in soil and compost environments within months. Thermoset bioplastics, while offering superior mechanical strength and heat resistance, often face challenges in biodegradability, resulting in longer degradation times and potential accumulation in ecosystems. The choice between TPS and thermoset bioplastics significantly influences waste management strategies and carbon footprint reduction in sustainable materials development.

Applications and Use Cases

Thermoplastic starch is widely used in packaging materials, disposable cutlery, and agricultural films due to its biodegradability and ease of processing through injection molding and extrusion. Thermoset bioplastics find applications in durable goods, automotive parts, and electronic casings where high mechanical strength, heat resistance, and dimensional stability are essential. The choice between thermoplastic starch and thermoset bioplastic depends on the intended use case, balancing biodegradability with performance requirements.

Challenges and Limitations

Thermoplastic starch faces challenges such as high water sensitivity and limited mechanical strength, which restrict its use in moisture-rich environments and applications requiring durability. Thermoset bioplastics often exhibit brittleness and difficulty in recycling due to their cross-linked polymer structure, limiting their sustainability and lifecycle management. Both types require advancements in formulation and processing to overcome these limitations for broader industrial adoption.

Future Trends in Bioplastic Development

Thermoplastic starch shows promising potential in future bioplastic development due to its biodegradability and compatibility with existing plastic processing technologies, allowing for scalable production and diverse applications. Thermoset bioplastics, while offering superior mechanical strength and thermal resistance, face challenges in recyclability, spurring research into recyclable thermoset formulations and bio-based curing agents. Innovations in reinforcing thermoplastic starch with nanomaterials and enhancing the recyclability of thermoset bioplastics are key trends driving sustainable material solutions in the bioplastics industry.

Thermoplastic starch vs Thermoset bioplastic Infographic

materialdif.com

materialdif.com