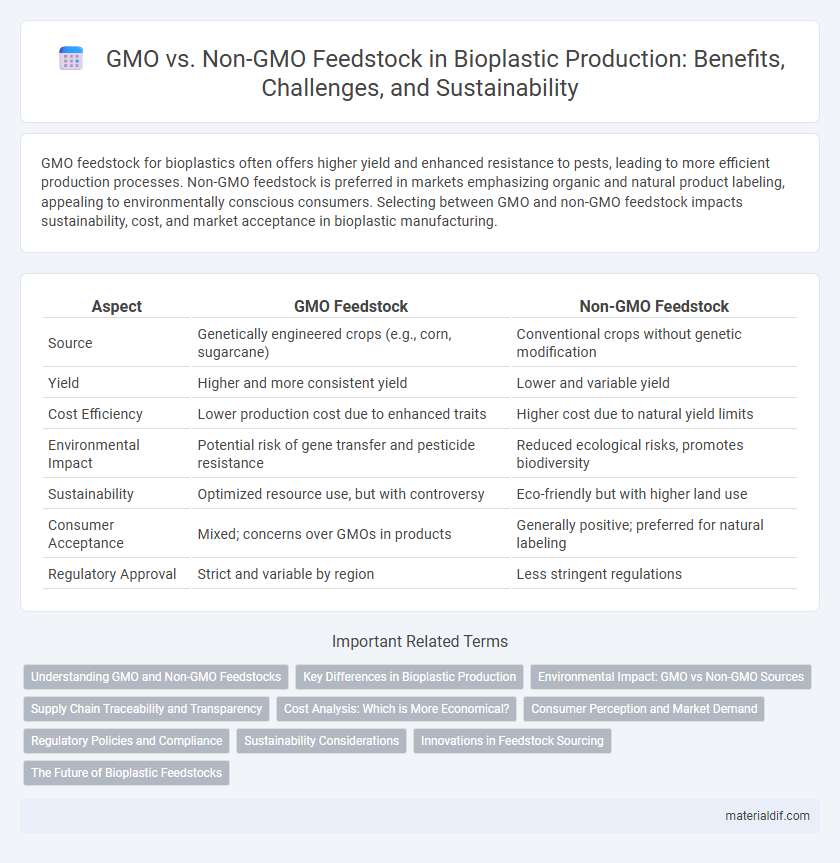

GMO feedstock for bioplastics often offers higher yield and enhanced resistance to pests, leading to more efficient production processes. Non-GMO feedstock is preferred in markets emphasizing organic and natural product labeling, appealing to environmentally conscious consumers. Selecting between GMO and non-GMO feedstock impacts sustainability, cost, and market acceptance in bioplastic manufacturing.

Table of Comparison

| Aspect | GMO Feedstock | Non-GMO Feedstock |

|---|---|---|

| Source | Genetically engineered crops (e.g., corn, sugarcane) | Conventional crops without genetic modification |

| Yield | Higher and more consistent yield | Lower and variable yield |

| Cost Efficiency | Lower production cost due to enhanced traits | Higher cost due to natural yield limits |

| Environmental Impact | Potential risk of gene transfer and pesticide resistance | Reduced ecological risks, promotes biodiversity |

| Sustainability | Optimized resource use, but with controversy | Eco-friendly but with higher land use |

| Consumer Acceptance | Mixed; concerns over GMOs in products | Generally positive; preferred for natural labeling |

| Regulatory Approval | Strict and variable by region | Less stringent regulations |

Understanding GMO and Non-GMO Feedstocks

GMO feedstocks in bioplastic production involve genetically modified organisms engineered for enhanced yield, resistance to pests, and optimized starch or cellulose content, improving efficiency and biomass quality. Non-GMO feedstocks derive from traditional crops cultivated without genetic modification, appealing to consumers seeking natural and eco-friendly alternatives, though they may have lower consistency in output. Understanding these differences influences feedstock selection based on sustainability goals, regulatory compliance, and market preferences within the bioplastics industry.

Key Differences in Bioplastic Production

GMO feedstock in bioplastic production offers enhanced crop yield and tailored polymer properties through genetic modifications, improving processing efficiency and material consistency. Non-GMO feedstock relies on conventional plant varieties, which may result in greater variability in bioplastic quality and slower biodegradation rates. The choice between GMO and non-GMO feedstocks directly impacts sustainability metrics, production cost, and consumer preference within the bioplastic industry.

Environmental Impact: GMO vs Non-GMO Sources

GMO feedstocks for bioplastics often enable higher crop yields and reduced pesticide use, potentially lowering the overall environmental footprint by minimizing land and chemical inputs. Non-GMO feedstocks may demand more extensive agricultural inputs and land area, leading to increased greenhouse gas emissions and biodiversity impacts. Lifecycle assessments reveal that selecting GMO sources can enhance resource efficiency, but concerns about ecosystem disruption and gene flow remain critical for sustainable bioplastic production.

Supply Chain Traceability and Transparency

GMO feedstock in bioplastic production offers enhanced supply chain traceability through genetic markers, enabling precise tracking from farm to final product, which reduces contamination risks and strengthens quality control. Non-GMO feedstock requires rigorous documentation and third-party certifications to ensure transparency, often involving more complex verification processes that may increase costs and time. Supply chain traceability and transparency are critical factors for both GMO and non-GMO feedstocks, impacting regulatory compliance, consumer trust, and sustainability claims in the bioplastic industry.

Cost Analysis: Which is More Economical?

GMO feedstock for bioplastic production generally offers higher yield and faster growth rates, reducing raw material costs compared to non-GMO feedstock. However, initial expenses related to genetically modified crop development and regulatory compliance can increase upfront investment. Non-GMO feedstock benefits from lower regulatory barriers and consumer preference, but often incurs higher production costs due to lower productivity and more land requirements.

Consumer Perception and Market Demand

Consumers increasingly prefer non-GMO feedstock for bioplastics due to concerns about environmental impact and health safety. Market demand shifts toward non-GMO options as brands aim to align with transparency and sustainability values. This trend drives innovation in sourcing and certification, influencing the bioplastic industry's growth trajectory.

Regulatory Policies and Compliance

Regulatory policies for bioplastics derived from GMO feedstock often require stringent compliance with biosafety assessments and labeling standards to ensure environmental and consumer safety. Non-GMO feedstock bioplastics typically face fewer regulatory barriers, though they must still comply with general sustainability and biodegradability criteria established by authorities like the EPA and EU regulations. Compliance frameworks prioritize transparency and traceability to support market acceptance and meet international trade requirements.

Sustainability Considerations

GMO feedstock for bioplastic production offers higher crop yields and reduced pesticide use, enhancing resource efficiency and lowering environmental impact. Non-GMO feedstock supports biodiversity and reduces gene flow risks, addressing ecological balance and consumer preference for natural products. Sustainability considerations weigh genetic modification benefits against ecosystem health, requiring integrated assessment of agricultural practices and long-term environmental outcomes.

Innovations in Feedstock Sourcing

Innovations in bioplastic feedstock sourcing emphasize the development of both GMO and non-GMO options to enhance sustainability and performance. GMO feedstocks are engineered for higher yield, pest resistance, and faster growth cycles, reducing land use and resource consumption, while non-GMO feedstocks focus on traditional crops and agricultural residues that avoid genetic modification concerns. Advances in biotechnology and agroecology facilitate optimized feedstock efficiency, enabling tailored bioplastic properties and expanded applications in eco-friendly materials.

The Future of Bioplastic Feedstocks

GMO feedstocks in bioplastic production offer enhanced yield, pest resistance, and tailored polymer properties, driving cost efficiency and scalability. Non-GMO feedstocks cater to eco-conscious markets by ensuring biodiversity preservation and reducing regulatory hurdles. Future bioplastic feedstocks will likely balance technological advancements in GMO traits with sustainable practices favored by non-GMO sources to meet global demand and environmental goals.

GMO feedstock vs Non-GMO feedstock Infographic

materialdif.com

materialdif.com