Blended bioplastics combine natural polymers with synthetic materials to enhance durability and reduce costs, offering a versatile solution for various applications. Pure bioplastics, derived entirely from renewable resources, provide superior biodegradability and environmental benefits but may lack the mechanical strength required for some uses. Choosing between blended and pure bioplastics depends on balancing performance requirements with sustainability goals.

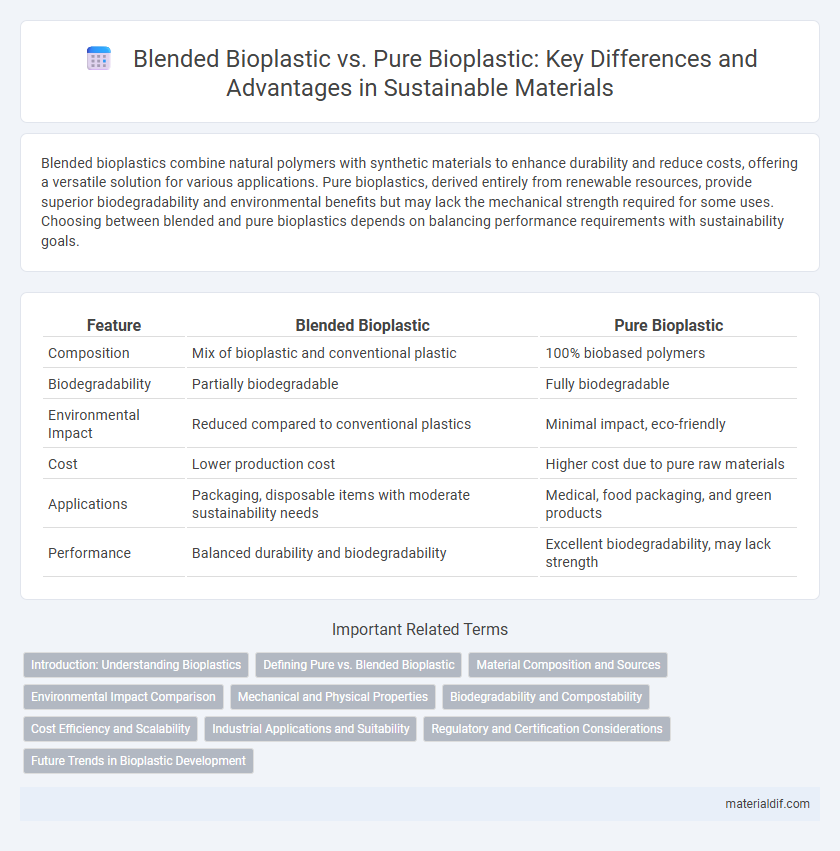

Table of Comparison

| Feature | Blended Bioplastic | Pure Bioplastic |

|---|---|---|

| Composition | Mix of bioplastic and conventional plastic | 100% biobased polymers |

| Biodegradability | Partially biodegradable | Fully biodegradable |

| Environmental Impact | Reduced compared to conventional plastics | Minimal impact, eco-friendly |

| Cost | Lower production cost | Higher cost due to pure raw materials |

| Applications | Packaging, disposable items with moderate sustainability needs | Medical, food packaging, and green products |

| Performance | Balanced durability and biodegradability | Excellent biodegradability, may lack strength |

Introduction: Understanding Bioplastics

Blended bioplastics combine natural polymers like starch or cellulose with synthetic plastics, enhancing mechanical properties and cost-efficiency while retaining partial biodegradability. Pure bioplastics are derived entirely from renewable biomass, such as polylactic acid (PLA) from cornstarch, offering complete biodegradability and lower carbon footprints. Understanding the differences in composition and environmental impact is essential for selecting appropriate bioplastic materials in sustainable packaging and product design.

Defining Pure vs. Blended Bioplastic

Pure bioplastic is derived entirely from renewable biomass such as corn starch or sugarcane, offering full biodegradability and compostability under industrial conditions. Blended bioplastic combines biopolymers with traditional petrochemical plastics or other additives to enhance mechanical properties, though this mixture may reduce biodegradability and complicate recycling processes. Understanding the distinct composition and environmental impact of pure versus blended bioplastics is crucial for selecting sustainable materials in packaging and product design.

Material Composition and Sources

Blended bioplastics combine renewable polymers such as polylactic acid (PLA) with traditional petrochemical-based plastics to enhance material properties like flexibility and durability, while pure bioplastics are derived entirely from biological sources like corn starch, sugarcane, or cellulose. The material composition of blended bioplastics allows partial biodegradability but often relies on non-renewable components, whereas pure bioplastics offer full biodegradability and are sourced 100% from sustainable biomass. Understanding the differences in biopolymer matrices and feedstock origins is critical for applications prioritizing environmental impact and end-of-life disposal.

Environmental Impact Comparison

Blended bioplastics combine biodegradable polymers with conventional plastics, resulting in partial degradability and reduced overall environmental benefits compared to pure bioplastics, which are fully biodegradable and compostable. Pure bioplastics minimize carbon footprint by utilizing renewable resources and breaking down completely without releasing toxic residues. Lifecycle assessments reveal that pure bioplastics significantly lower greenhouse gas emissions and reduce landfill waste more effectively than blended counterparts.

Mechanical and Physical Properties

Blended bioplastics combine biopolymer components to enhance mechanical strength, flexibility, and impact resistance compared to pure bioplastics, which often exhibit brittleness and lower tensile strength. The addition of fillers or other polymers in blended bioplastics improves thermal stability and moisture resistance, optimizing physical durability for diverse applications. Pure bioplastics maintain higher biodegradability but tend to have less favorable mechanical properties for structural uses.

Biodegradability and Compostability

Blended bioplastics combine bio-based polymers with synthetic additives, often reducing their biodegradability and compostability compared to pure bioplastics made entirely from natural materials like polylactic acid (PLA) or starch. Pure bioplastics generally exhibit higher rates of microbial degradation under industrial composting conditions, ensuring complete breakdown within weeks to months. The presence of conventional plastics in blended bioplastics can hinder composting processes by leaving residues harmful to soil quality and limiting their classification as certified compostable products.

Cost Efficiency and Scalability

Blended bioplastics combine biodegradable polymers with conventional plastics, reducing raw material costs and enabling easier integration into existing manufacturing processes, thus enhancing cost efficiency. Pure bioplastics, derived entirely from renewable sources like polylactic acid (PLA) or polyhydroxyalkanoates (PHA), often incur higher production costs due to specialized extraction and processing methods, limiting scalability. Blended bioplastics benefit from improved scalability through compatibility with current industrial equipment, making them a pragmatic choice for large-scale applications seeking cost-effective sustainability.

Industrial Applications and Suitability

Blended bioplastics, combining biopolymers with conventional plastics, offer enhanced mechanical strength and processability, making them suitable for diverse industrial applications such as packaging, automotive parts, and consumer goods. Pure bioplastics, derived solely from renewable biomass like polylactic acid (PLA) or polyhydroxyalkanoates (PHA), provide superior biodegradability and compostability, which is ideal for industries prioritizing sustainability and environmental compliance. Industrial suitability depends on balancing performance requirements with end-of-life metrics, where blended bioplastics excel in durability, and pure bioplastics lead in eco-friendly disposal.

Regulatory and Certification Considerations

Blended bioplastics often face complex regulatory landscapes due to the presence of multiple materials, requiring thorough testing and certification to ensure compliance with biodegradability and compostability standards such as EN 13432 and ASTM D6400. Pure bioplastics typically achieve certification more straightforwardly since their composition aligns closely with established criteria for renewable content and environmental safety. Regulatory authorities prioritize transparency and traceability in blended formulations to prevent claims of biodegradability that may not fully apply, making certification processes more stringent and costly.

Future Trends in Bioplastic Development

Blended bioplastics, combining natural polymers with synthetic materials, offer enhanced mechanical properties and cost-effectiveness, driving their adoption in packaging and automotive industries. Pure bioplastics, derived solely from renewable resources, emphasize biodegradability and environmental sustainability, aligning with stricter global regulations on plastic waste. Future trends indicate increased innovation in molecular design and fermentation processes to improve performance, scalability, and lifecycle impact of both blended and pure bioplastics.

Blended bioplastic vs Pure bioplastic Infographic

materialdif.com

materialdif.com