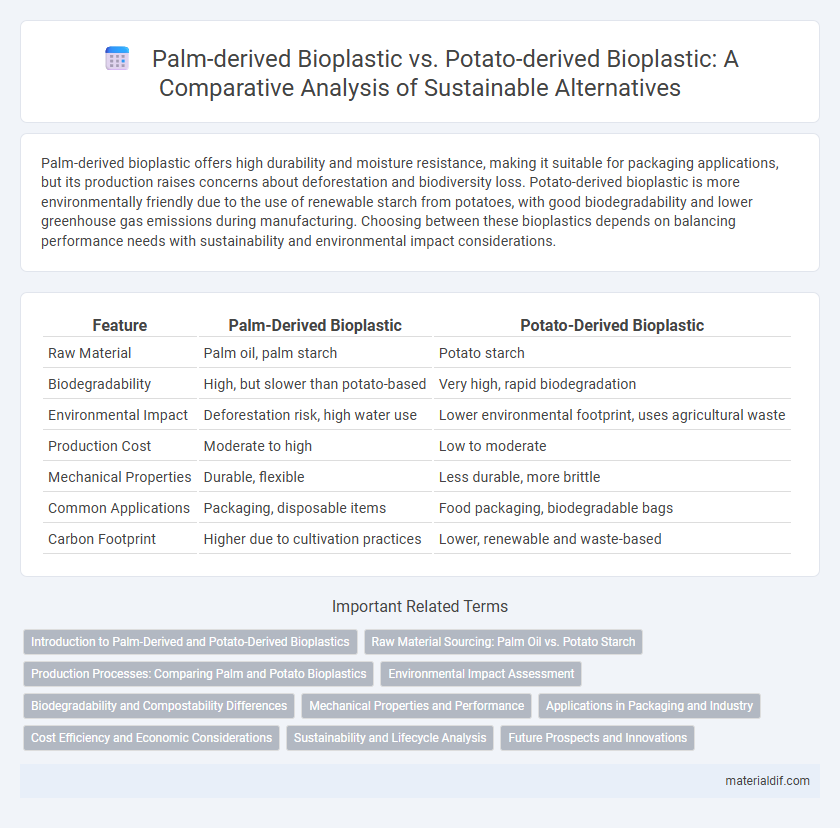

Palm-derived bioplastic offers high durability and moisture resistance, making it suitable for packaging applications, but its production raises concerns about deforestation and biodiversity loss. Potato-derived bioplastic is more environmentally friendly due to the use of renewable starch from potatoes, with good biodegradability and lower greenhouse gas emissions during manufacturing. Choosing between these bioplastics depends on balancing performance needs with sustainability and environmental impact considerations.

Table of Comparison

| Feature | Palm-Derived Bioplastic | Potato-Derived Bioplastic |

|---|---|---|

| Raw Material | Palm oil, palm starch | Potato starch |

| Biodegradability | High, but slower than potato-based | Very high, rapid biodegradation |

| Environmental Impact | Deforestation risk, high water use | Lower environmental footprint, uses agricultural waste |

| Production Cost | Moderate to high | Low to moderate |

| Mechanical Properties | Durable, flexible | Less durable, more brittle |

| Common Applications | Packaging, disposable items | Food packaging, biodegradable bags |

| Carbon Footprint | Higher due to cultivation practices | Lower, renewable and waste-based |

Introduction to Palm-Derived and Potato-Derived Bioplastics

Palm-derived bioplastics are produced from oils extracted from oil palm fruits, offering high biodegradability and significant potential for reducing fossil fuel dependence in packaging and agriculture. Potato-derived bioplastics utilize starch from potatoes, providing a renewable resource that is easily biodegradable and commonly used in food packaging and disposable items. Both types of bioplastics present sustainable alternatives to conventional plastics, with distinct source materials influencing their mechanical properties and environmental impacts.

Raw Material Sourcing: Palm Oil vs. Potato Starch

Palm-derived bioplastic relies on palm oil, a renewable resource obtained from the fruit of oil palm trees, known for high yield per hectare but associated with deforestation and habitat loss concerns. Potato-derived bioplastic utilizes potato starch, a biodegradable polysaccharide extracted from tubers, offering a more localized and sustainable raw material source with lower environmental impact. Sourcing palm oil involves large-scale plantations primarily in tropical regions, whereas potato starch can be sourced from temperate climates with existing agricultural infrastructure, influencing regional production feasibility and carbon footprint.

Production Processes: Comparing Palm and Potato Bioplastics

Palm-derived bioplastic production primarily involves extracting cellulose or starch from palm biomass, followed by fermentation and polymerization to create biopolymers such as polylactic acid (PLA) or polyhydroxyalkanoates (PHA). Potato-derived bioplastic production focuses on isolating potato starch, which undergoes gelatinization and enzymatic conversion before being processed into biodegradable plastics like thermoplastic starch (TPS) or blended bioplastics. The palm-based process often benefits from higher biomass yield and oil content, enhancing polymer quality, whereas potato-based production leverages abundant starch availability and lower lipid interference for cost-effective bioplastic synthesis.

Environmental Impact Assessment

Palm-derived bioplastics often involve deforestation and habitat loss due to palm oil cultivation, resulting in significant carbon emissions and biodiversity reduction. Potato-derived bioplastics generally have a lower environmental footprint, as potatoes can be grown on marginal lands with less impact on forests and wildlife. Life cycle assessments reveal that potato-based bioplastics generate fewer greenhouse gases and require less water compared to palm-based alternatives, enhancing overall sustainability.

Biodegradability and Compostability Differences

Palm-derived bioplastics generally exhibit slower biodegradability and reduced compostability compared to potato-derived bioplastics due to their higher lignin content and denser molecular structure. Potato-derived bioplastics break down more rapidly in industrial composting environments, benefiting from starch-based polymers that microbial activity more easily metabolizes. These differences significantly impact environmental waste management strategies by influencing degradation rates and suitability for various composting facilities.

Mechanical Properties and Performance

Palm-derived bioplastics exhibit higher tensile strength and better moisture resistance compared to potato-derived bioplastics, making them suitable for durable packaging applications. Potato-derived bioplastics offer greater flexibility and biodegradability but tend to have lower mechanical stability under stress. The choice between palm and potato-based bioplastics depends on the specific performance requirements such as strength versus compostability.

Applications in Packaging and Industry

Palm-derived bioplastics offer high moisture resistance and durability, making them ideal for rigid packaging applications such as containers and trays in the food industry. Potato-derived bioplastics provide excellent flexibility and biodegradability, suited for film packaging like bags and wraps used in agricultural and retail sectors. Both materials contribute to sustainable solutions, with palm-based bioplastics favored for strength and potato-based variants preferred for compostable packaging needs.

Cost Efficiency and Economic Considerations

Palm-derived bioplastic offers higher cost efficiency due to the abundant availability of palm oil, leading to lower raw material expenses and scalable production advantages. Potato-derived bioplastic incurs higher costs primarily from limited crop yield and intensive processing requirements, resulting in less competitive pricing. Economic considerations favor palm-based bioplastics for large-scale industrial applications where cost reduction and supply reliability are critical factors.

Sustainability and Lifecycle Analysis

Palm-derived bioplastic shows higher yield per hectare but raises significant sustainability concerns due to deforestation, biodiversity loss, and carbon emissions associated with palm oil plantations. Potato-derived bioplastic offers a lower environmental impact, benefiting from crop rotation and lower land-use intensity, although its overall yield is less efficient compared to palm-based sources. Lifecycle analysis reveals potato-based bioplastics generally have a smaller carbon footprint and reduced water consumption, making them a more sustainable alternative in regions where agricultural practices prioritize ecological balance.

Future Prospects and Innovations

Palm-derived bioplastics exhibit promising scalability due to abundant raw material availability and ongoing advancements in enzyme-catalyzed polymerization enhancing biodegradability. Potato-derived bioplastics innovate through enhanced film-forming properties and integration with nanocellulose to improve mechanical strength and water resistance, positioning them well for packaging applications. Future prospects for both focus on genetic engineering to optimize starch yield and polymer quality, driving sustainable alternatives to petroleum-based plastics.

Palm-derived bioplastic vs Potato-derived bioplastic Infographic

materialdif.com

materialdif.com