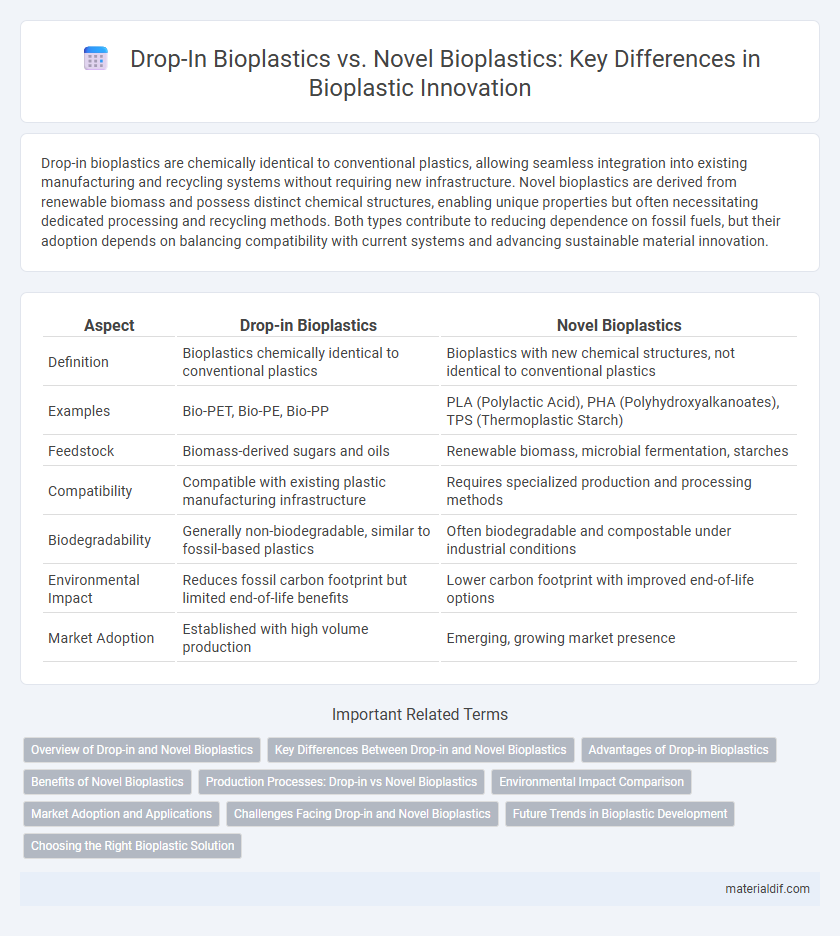

Drop-in bioplastics are chemically identical to conventional plastics, allowing seamless integration into existing manufacturing and recycling systems without requiring new infrastructure. Novel bioplastics are derived from renewable biomass and possess distinct chemical structures, enabling unique properties but often necessitating dedicated processing and recycling methods. Both types contribute to reducing dependence on fossil fuels, but their adoption depends on balancing compatibility with current systems and advancing sustainable material innovation.

Table of Comparison

| Aspect | Drop-in Bioplastics | Novel Bioplastics |

|---|---|---|

| Definition | Bioplastics chemically identical to conventional plastics | Bioplastics with new chemical structures, not identical to conventional plastics |

| Examples | Bio-PET, Bio-PE, Bio-PP | PLA (Polylactic Acid), PHA (Polyhydroxyalkanoates), TPS (Thermoplastic Starch) |

| Feedstock | Biomass-derived sugars and oils | Renewable biomass, microbial fermentation, starches |

| Compatibility | Compatible with existing plastic manufacturing infrastructure | Requires specialized production and processing methods |

| Biodegradability | Generally non-biodegradable, similar to fossil-based plastics | Often biodegradable and compostable under industrial conditions |

| Environmental Impact | Reduces fossil carbon footprint but limited end-of-life benefits | Lower carbon footprint with improved end-of-life options |

| Market Adoption | Established with high volume production | Emerging, growing market presence |

Overview of Drop-in and Novel Bioplastics

Drop-in bioplastics, chemically identical to their petroleum-derived counterparts, seamlessly integrate into existing manufacturing and recycling systems, offering a sustainable alternative without altering product performance. Novel bioplastics, derived from bio-based monomers, present unique molecular structures that enable tailored properties and biodegradability, expanding applications beyond traditional plastics. Understanding the distinctions in composition, processing, and end-of-life options is essential for optimizing material selection in eco-friendly packaging and product development.

Key Differences Between Drop-in and Novel Bioplastics

Drop-in bioplastics are chemically identical to conventional plastics, allowing seamless integration into existing manufacturing and recycling systems without modifications, whereas novel bioplastics are new polymers with distinct chemical structures requiring specialized processing and waste management. Drop-in bioplastics primarily use bio-based feedstocks to reduce carbon footprint while maintaining performance, while novel bioplastics offer enhanced biodegradability and tailor-made properties for specific applications. The choice between drop-in and novel bioplastics hinges on balancing compatibility with current infrastructure and achieving environmental benefits through innovation in polymer chemistry.

Advantages of Drop-in Bioplastics

Drop-in bioplastics offer significant advantages by seamlessly integrating with existing petrochemical processing infrastructure and supply chains, reducing the need for costly modifications. Their chemical compatibility with conventional plastics enables easy recycling and broad market acceptance without compromising product performance. This compatibility accelerates adoption and lowers environmental impact by substituting fossil-based materials with renewable biomass sources.

Benefits of Novel Bioplastics

Novel bioplastics offer enhanced biodegradability and lower environmental impact compared to drop-in bioplastics, which are chemically identical to conventional plastics. They are often derived from renewable resources with reduced carbon footprints and can degrade under natural conditions, minimizing plastic pollution. Innovations in novel bioplastics also enable tailored material properties for specific applications, improving performance and sustainability across industries.

Production Processes: Drop-in vs Novel Bioplastics

Drop-in bioplastics utilize existing petrochemical production infrastructure, enabling seamless integration by replacing fossil-based polymers with bio-based feedstocks without altering manufacturing processes. Novel bioplastics require new production pathways involving distinct biochemical or microbial synthesis methods, often demanding innovative reactors and catalysts tailored to unique polymer chemistries. These differences influence scalability, cost-effectiveness, and environmental impact across lifecycle assessments.

Environmental Impact Comparison

Drop-in bioplastics, derived from renewable resources but chemically identical to conventional plastics, offer compatibility with existing recycling systems, minimizing environmental disruption. Novel bioplastics, often bio-based and biodegradable, can reduce long-term pollution but may require new waste management infrastructure and pose challenges in compostability standards. Life cycle assessments reveal that while drop-in bioplastics lower fossil carbon use, novel bioplastics potentially achieve greater reductions in greenhouse gas emissions and plastic persistence in ecosystems.

Market Adoption and Applications

Drop-in bioplastics, chemically identical to conventional plastics, benefit from seamless integration into existing manufacturing and recycling systems, driving faster market adoption primarily in packaging, automotive, and consumer goods. Novel bioplastics, derived from new bio-based polymers, offer unique properties and biodegradability but face slower adoption due to challenges in scaling production, cost, and infrastructure compatibility. Market trends show increasing demand for drop-in bioplastics driven by regulatory pressures and consumer preference, while novel bioplastics gain traction in niche applications emphasizing sustainability and end-of-life environmental impact.

Challenges Facing Drop-in and Novel Bioplastics

Drop-in bioplastics face significant challenges in terms of compatibility with existing petrochemical infrastructure and limited improvements in environmental performance compared to traditional plastics. Novel bioplastics encounter obstacles related to high production costs, uncertain regulatory approval, and scalability issues in manufacturing processes. Both types require advancements in feedstock availability and recycling technologies to enhance their viability and market adoption.

Future Trends in Bioplastic Development

Drop-in bioplastics, chemically identical to conventional plastics, enable seamless integration into existing manufacturing and recycling systems, driving near-term adoption. Novel bioplastics, derived from new bio-based monomers, offer enhanced biodegradability and functional properties, aligning with sustainability goals and circular economy initiatives. Emerging trends emphasize advances in microbial fermentation, renewable feedstocks, and enzyme engineering to improve performance and cost-efficiency of both drop-in and novel bioplastics for future applications.

Choosing the Right Bioplastic Solution

Drop-in bioplastics, such as bio-based polyethylene and PET, offer seamless integration with existing petrochemical manufacturing processes, ensuring compatibility and ease of scale-up. Novel bioplastics like polylactic acid (PLA) and polyhydroxyalkanoates (PHA) provide unique biodegradability and compostability benefits but may require specialized processing and waste management systems. Selecting the right bioplastic solution depends on balancing performance requirements, environmental impact goals, and existing infrastructure compatibility.

Drop-in bioplastics vs Novel bioplastics Infographic

materialdif.com

materialdif.com