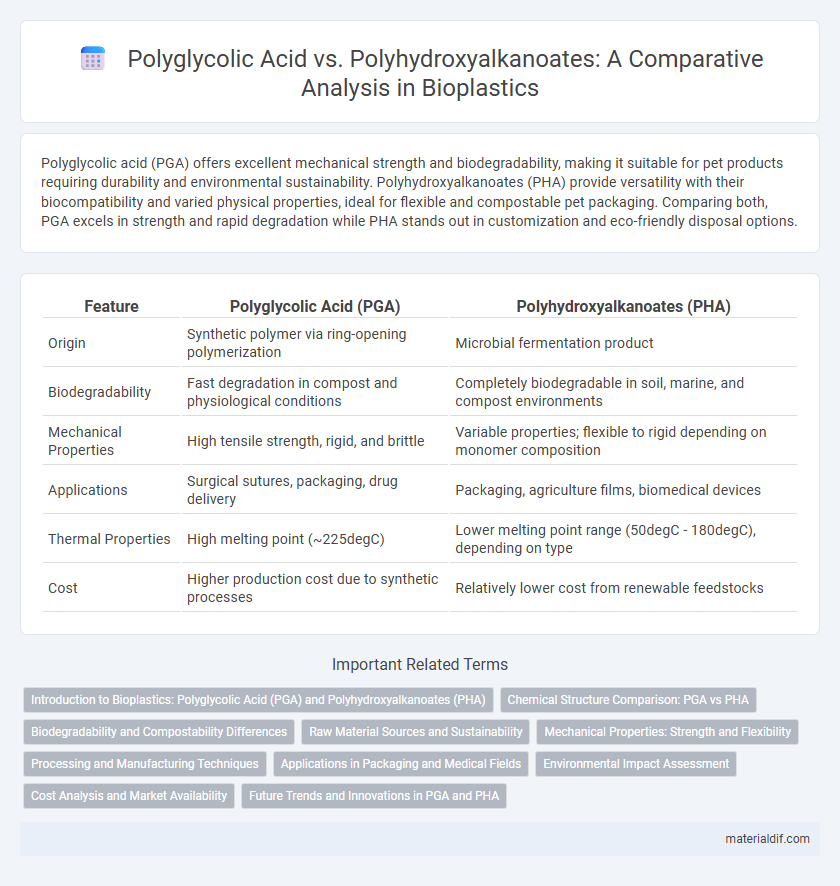

Polyglycolic acid (PGA) offers excellent mechanical strength and biodegradability, making it suitable for pet products requiring durability and environmental sustainability. Polyhydroxyalkanoates (PHA) provide versatility with their biocompatibility and varied physical properties, ideal for flexible and compostable pet packaging. Comparing both, PGA excels in strength and rapid degradation while PHA stands out in customization and eco-friendly disposal options.

Table of Comparison

| Feature | Polyglycolic Acid (PGA) | Polyhydroxyalkanoates (PHA) |

|---|---|---|

| Origin | Synthetic polymer via ring-opening polymerization | Microbial fermentation product |

| Biodegradability | Fast degradation in compost and physiological conditions | Completely biodegradable in soil, marine, and compost environments |

| Mechanical Properties | High tensile strength, rigid, and brittle | Variable properties; flexible to rigid depending on monomer composition |

| Applications | Surgical sutures, packaging, drug delivery | Packaging, agriculture films, biomedical devices |

| Thermal Properties | High melting point (~225degC) | Lower melting point range (50degC - 180degC), depending on type |

| Cost | Higher production cost due to synthetic processes | Relatively lower cost from renewable feedstocks |

Introduction to Bioplastics: Polyglycolic Acid (PGA) and Polyhydroxyalkanoates (PHA)

Polyglycolic Acid (PGA) and Polyhydroxyalkanoates (PHA) represent two prominent types of bioplastics derived from renewable resources with distinct biodegradation properties. PGA is known for its high strength, fast hydrolytic degradation, and extensive use in medical sutures, while PHA, produced by microbial fermentation, offers versatility with its varied monomer composition and eco-friendly compostability. Both bioplastics contribute to reducing plastic pollution through sustainable production and enhanced end-of-life biodegradability in soil or marine environments.

Chemical Structure Comparison: PGA vs PHA

Polyglycolic acid (PGA) is a linear aliphatic polyester with repeating glycolic acid units, giving it a simple, highly crystalline structure that contributes to its high tensile strength and rapid biodegradability. Polyhydroxyalkanoates (PHA) are a diverse family of biopolyesters produced by microbial fermentation, characterized by hydroxyalkanoate monomers with variable side chains, resulting in structures ranging from highly crystalline to amorphous. The chemical structure of PGA is uniform and consists of repeating ester linkages between glycolic acid units, while PHA's structure varies with its monomer composition, offering tunable mechanical and degradation properties ideal for diverse bioplastic applications.

Biodegradability and Compostability Differences

Polyglycolic acid (PGA) exhibits rapid biodegradability under industrial composting conditions due to its high hydrolysis rate, effectively breaking down into non-toxic byproducts within weeks. Polyhydroxyalkanoates (PHAs), produced by microbial fermentation, offer superior biodegradability across diverse environments including soil, marine, and home composting, decomposing naturally without harmful residues. Unlike PGA, PHAs' compostability extends to lower temperature ranges and less controlled settings, making them more versatile for sustainable waste management.

Raw Material Sources and Sustainability

Polyglycolic acid (PGA) is primarily synthesized from glycolic acid derived from petrochemical sources or renewable feedstocks such as sugarcane, offering a biodegradable option with a relatively narrow raw material base. Polyhydroxyalkanoates (PHAs) are bioplastics produced by bacterial fermentation of diverse organic substrates including agricultural waste, plant oils, and industrial by-products, enhancing their sustainability profile through resource circularity. The broader raw material versatility and complete biodegradability of PHAs contribute to lower environmental impact compared to PGA, which depends more on specific fermentation routes and feedstock availability.

Mechanical Properties: Strength and Flexibility

Polyglycolic acid (PGA) exhibits high tensile strength and rigidity, making it suitable for applications requiring structural integrity but with limited flexibility. Polyhydroxyalkanoates (PHAs) offer a broad range of mechanical properties, including notable flexibility and moderate strength, which vary depending on the specific monomer composition. The balance between strength and elasticity in PHAs allows for versatile use in packaging and biomedical devices, whereas PGA's superior strength favors load-bearing biomedical implants.

Processing and Manufacturing Techniques

Polyglycolic acid (PGA) is processed mainly through ring-opening polymerization of glycolide, which enables high molecular weight polymers with excellent mechanical properties suitable for injection molding and extrusion. Polyhydroxyalkanoates (PHAs) are biosynthesized by microbial fermentation of renewable substrates, followed by solvent extraction or mechanical separation; this bio-based production allows for versatile manufacturing techniques including film casting, fiber spinning, and 3D printing. Both materials require precise control of processing parameters such as temperature and moisture to maintain polymer integrity and optimize product performance in applications ranging from medical devices to packaging.

Applications in Packaging and Medical Fields

Polyglycolic acid (PGA) is widely used in medical sutures and drug delivery systems due to its high strength and biodegradability, making it ideal for temporary implants and absorbable medical devices. Polyhydroxyalkanoates (PHA) are favored in packaging applications for their excellent biodegradability and adaptability in producing flexible films, containers, and coatings that reduce environmental impact. Both bioplastics contribute to sustainable solutions, with PGA excelling in medical fields and PHA providing versatile options for eco-friendly packaging materials.

Environmental Impact Assessment

Polyglycolic acid (PGA) demonstrates rapid biodegradability in both industrial composting and aquatic environments, contributing to a low environmental footprint by minimizing persistent plastic waste. Polyhydroxyalkanoates (PHAs) are biopolyesters produced by microbial fermentation with the advantage of complete biodegradation in soil, freshwater, and marine conditions, reducing long-term pollution and microplastic accumulation. Life cycle assessments highlight that PHAs generally exhibit lower greenhouse gas emissions and energy consumption compared to PGA, making PHAs a more sustainable choice for reducing environmental impact.

Cost Analysis and Market Availability

Polyglycolic acid (PGA) generally incurs higher production costs due to its petrochemical-based synthesis and complex manufacturing processes, limiting its widespread market availability primarily to medical and packaging niches. In contrast, polyhydroxyalkanoates (PHA) benefit from fermentation of renewable resources, resulting in more scalable production and lower costs that enhance their presence in diverse markets such as agriculture, packaging, and biomedical applications. Market analysis indicates that PHA's biodegradable properties and cost-effectiveness drive increasing demand and expanded commercial adoption, whereas PGA remains specialized with constrained supply chains.

Future Trends and Innovations in PGA and PHA

Polyglycolic acid (PGA) is advancing through innovations in enhanced biodegradability and improved mechanical properties for medical and packaging applications. Polyhydroxyalkanoates (PHA) are experiencing growth driven by bio-based production methods using renewable feedstocks and genetic engineering to optimize polymer yield and properties. Future trends emphasize scalable manufacturing processes and hybrid materials combining PGA and PHA to meet sustainability and performance demands in various industries.

Polyglycolic acid vs Polyhydroxyalkanoates Infographic

materialdif.com

materialdif.com