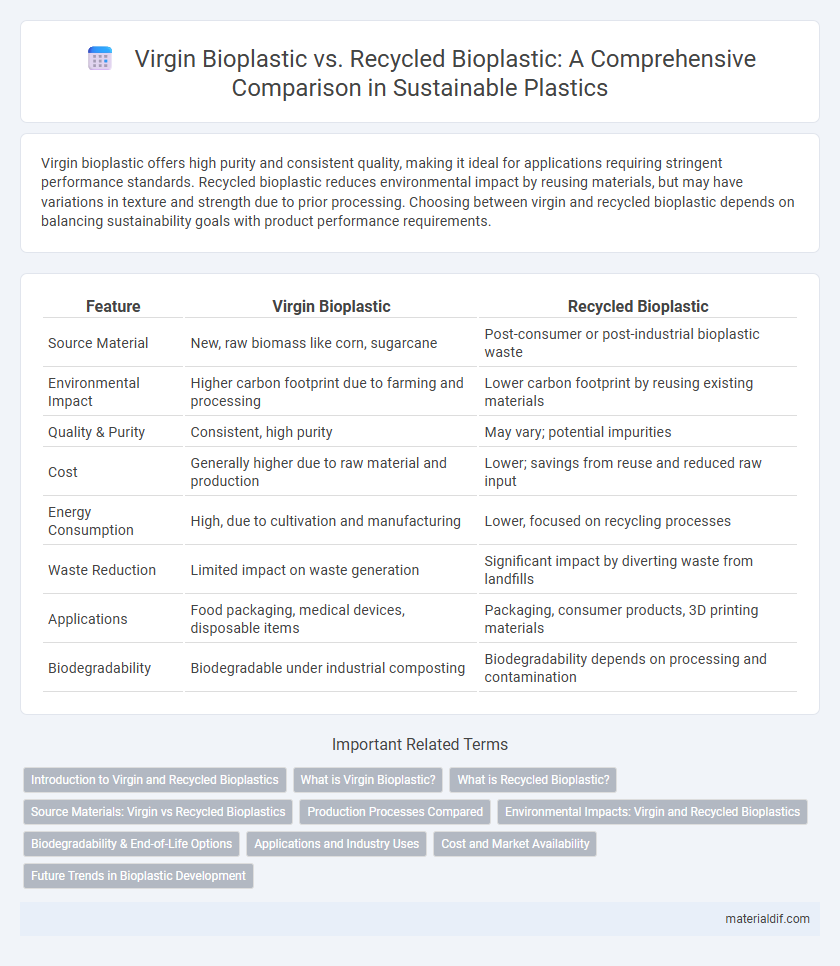

Virgin bioplastic offers high purity and consistent quality, making it ideal for applications requiring stringent performance standards. Recycled bioplastic reduces environmental impact by reusing materials, but may have variations in texture and strength due to prior processing. Choosing between virgin and recycled bioplastic depends on balancing sustainability goals with product performance requirements.

Table of Comparison

| Feature | Virgin Bioplastic | Recycled Bioplastic |

|---|---|---|

| Source Material | New, raw biomass like corn, sugarcane | Post-consumer or post-industrial bioplastic waste |

| Environmental Impact | Higher carbon footprint due to farming and processing | Lower carbon footprint by reusing existing materials |

| Quality & Purity | Consistent, high purity | May vary; potential impurities |

| Cost | Generally higher due to raw material and production | Lower; savings from reuse and reduced raw input |

| Energy Consumption | High, due to cultivation and manufacturing | Lower, focused on recycling processes |

| Waste Reduction | Limited impact on waste generation | Significant impact by diverting waste from landfills |

| Applications | Food packaging, medical devices, disposable items | Packaging, consumer products, 3D printing materials |

| Biodegradability | Biodegradable under industrial composting | Biodegradability depends on processing and contamination |

Introduction to Virgin and Recycled Bioplastics

Virgin bioplastics are produced directly from renewable biomass sources such as corn starch, sugarcane, or cellulose, offering high purity and consistent quality for manufacturing. Recycled bioplastics derive from post-consumer or post-industrial bioplastic waste, reducing environmental impact by minimizing resource consumption and waste generation. Both types play significant roles in the bioplastic industry, balancing sustainability goals with material performance requirements.

What is Virgin Bioplastic?

Virgin bioplastic is a type of bioplastic produced directly from natural, renewable raw materials such as corn starch, sugarcane, or cellulose without prior processing or recycling. It offers high purity and consistent material properties, making it suitable for applications requiring stringent quality standards. Compared to recycled bioplastics, virgin bioplastics typically have better mechanical strength and fewer contaminants, enhancing their performance in packaging and medical products.

What is Recycled Bioplastic?

Recycled bioplastic is produced by reprocessing bioplastic materials that have already been used, reducing the demand for virgin bioplastic derived from new biomass. This method involves collecting, sorting, and breaking down used bioplastics into raw materials that can be remanufactured into new products, supporting a circular economy. Recycled bioplastics help minimize environmental impact by conserving resources and lowering greenhouse gas emissions compared to producing virgin bioplastic from fresh feedstock.

Source Materials: Virgin vs Recycled Bioplastics

Virgin bioplastics are derived from freshly sourced, renewable raw materials such as corn starch, sugarcane, or cellulose, ensuring high purity and consistent polymer quality. Recycled bioplastics utilize post-consumer or post-industrial bio-based plastic waste, reducing reliance on new biomass and lowering environmental impact by diverting materials from landfills. The choice between virgin and recycled bioplastics hinges on balancing raw material availability, production costs, and sustainability goals.

Production Processes Compared

Virgin bioplastic production involves synthesizing polymers directly from renewable biomass such as corn starch or sugarcane, requiring significant energy input to convert raw materials into biodegradable plastics. Recycled bioplastic production incorporates post-consumer or post-industrial bioplastic waste, undergoing processes such as collection, sorting, cleaning, and reprocessing through extrusion or pelletizing, which reduces raw material consumption and lowers carbon emissions. The comparative energy efficiency and environmental impact of recycled bioplastics depend on the efficiency of waste collection systems and contamination levels in the input material.

Environmental Impacts: Virgin and Recycled Bioplastics

Virgin bioplastic production consumes more natural resources and generates higher greenhouse gas emissions compared to recycled bioplastic, which utilizes existing materials and reduces waste. Recycled bioplastics lower environmental impact by minimizing landfill contribution and decreasing energy consumption during manufacturing. Life cycle assessments consistently show that recycled bioplastics have a smaller carbon footprint and conserve more raw materials than virgin counterparts.

Biodegradability & End-of-Life Options

Virgin bioplastics, derived from fresh biomass, often exhibit higher purity and better controlled biodegradability, making them suitable for specific composting facilities. Recycled bioplastics may contain mixed polymer blends that can slow degradation rates and complicate end-of-life processing, sometimes requiring advanced recycling or energy recovery methods. Biodegradability and end-of-life options for both types depend heavily on material composition, local waste management infrastructure, and certification standards like EN 13432 or ASTM D6400.

Applications and Industry Uses

Virgin bioplastic, derived from fresh biomass such as corn starch or sugarcane, is widely used in food packaging, medical devices, and single-use items due to its consistent quality and purity. Recycled bioplastic, made from collected and processed bioplastic waste, finds increasing applications in automotive parts, construction materials, and durable consumer goods where material variability and cost efficiency are prioritized. Industries including packaging, automotive, and consumer electronics are progressively adopting recycled bioplastic to enhance sustainability while maintaining functional performance.

Cost and Market Availability

Virgin bioplastic typically incurs higher production costs due to reliance on new raw materials derived from renewable resources, limiting its market availability primarily to premium segments. Recycled bioplastic offers a cost-effective alternative by utilizing post-consumer or industrial bioplastic waste, increasing its presence in mainstream markets while supporting circular economy practices. Market trends indicate a growing demand for recycled bioplastics as manufacturers seek sustainable and economically viable materials to meet regulatory and consumer expectations.

Future Trends in Bioplastic Development

Virgin bioplastic offers high purity and consistent properties essential for advanced applications, while recycled bioplastic supports circular economy principles by reducing waste and lowering carbon footprints. Emerging trends highlight enhanced enzymatic recycling techniques and bio-based feedstocks to improve recycled bioplastic quality, fostering scalability and cost-effectiveness. Industry projections indicate increasing integration of hybrid virgin-recycled formulations to optimize performance and sustainability in packaging, automotive, and consumer goods sectors.

Virgin bioplastic vs Recycled bioplastic Infographic

materialdif.com

materialdif.com