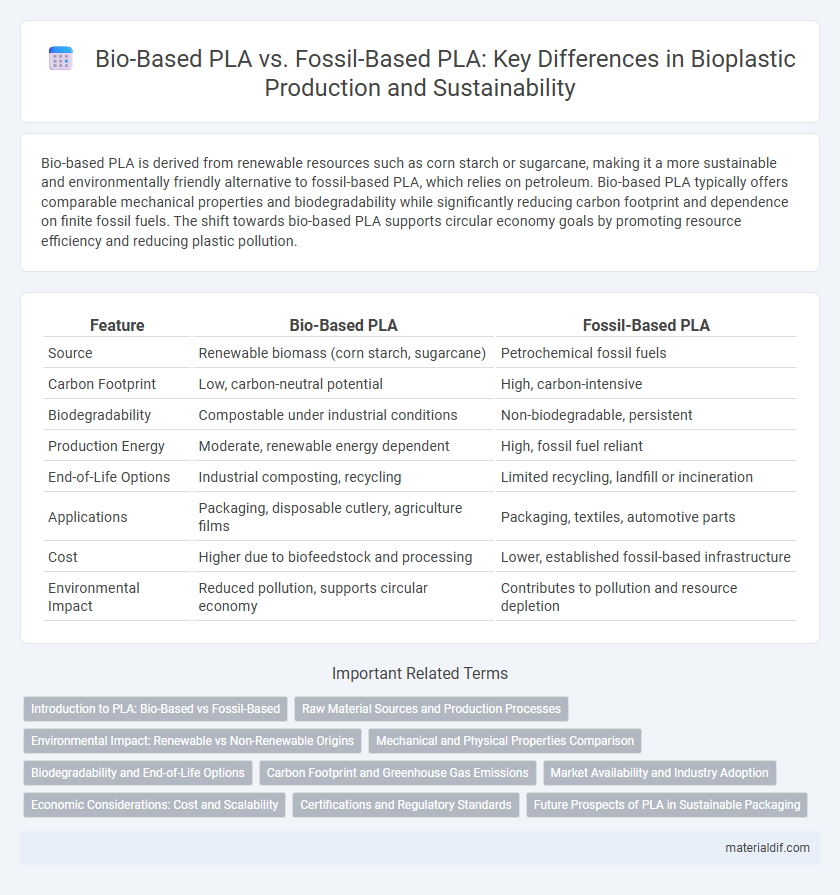

Bio-based PLA is derived from renewable resources such as corn starch or sugarcane, making it a more sustainable and environmentally friendly alternative to fossil-based PLA, which relies on petroleum. Bio-based PLA typically offers comparable mechanical properties and biodegradability while significantly reducing carbon footprint and dependence on finite fossil fuels. The shift towards bio-based PLA supports circular economy goals by promoting resource efficiency and reducing plastic pollution.

Table of Comparison

| Feature | Bio-Based PLA | Fossil-Based PLA |

|---|---|---|

| Source | Renewable biomass (corn starch, sugarcane) | Petrochemical fossil fuels |

| Carbon Footprint | Low, carbon-neutral potential | High, carbon-intensive |

| Biodegradability | Compostable under industrial conditions | Non-biodegradable, persistent |

| Production Energy | Moderate, renewable energy dependent | High, fossil fuel reliant |

| End-of-Life Options | Industrial composting, recycling | Limited recycling, landfill or incineration |

| Applications | Packaging, disposable cutlery, agriculture films | Packaging, textiles, automotive parts |

| Cost | Higher due to biofeedstock and processing | Lower, established fossil-based infrastructure |

| Environmental Impact | Reduced pollution, supports circular economy | Contributes to pollution and resource depletion |

Introduction to PLA: Bio-Based vs Fossil-Based

PLA, or polylactic acid, is a versatile polymer derived either from renewable biomass sources like corn starch in bio-based PLA or from petroleum feedstocks in fossil-based PLA. Bio-based PLA offers enhanced sustainability through reduced carbon footprint and biodegradability potential, while fossil-based PLA relies on finite fossil resources with a higher environmental impact. Understanding the differences in raw material origin and environmental implications is essential for optimizing applications in packaging, agriculture, and biomedical fields.

Raw Material Sources and Production Processes

Bio-Based PLA is derived primarily from renewable resources such as corn starch, sugarcane, or cassava, utilizing fermentation processes to produce lactic acid as its monomer. Fossil-Based PLA, while chemically similar, is synthesized from petrochemical feedstocks, relying on non-renewable fossil fuels and energy-intensive catalytic polymerization methods. The bio-based production route reduces carbon footprint significantly by incorporating sustainable agricultural inputs and biotechnological advancements in fermentation, contrasting with the higher environmental impact associated with fossil-derived chemical processes.

Environmental Impact: Renewable vs Non-Renewable Origins

Bio-Based PLA derives from renewable resources like corn starch or sugarcane, significantly reducing greenhouse gas emissions compared to fossil-based PLA, which relies on non-renewable petroleum. The production of bio-based PLA supports lower carbon footprints and enhanced biodegradability, contributing to sustainable waste management. In contrast, fossil-based PLA's environmental impact includes higher energy consumption and increased dependency on finite fossil fuels, exacerbating climate change concerns.

Mechanical and Physical Properties Comparison

Bio-based PLA exhibits comparable mechanical strength, tensile properties, and thermal stability to fossil-based PLA, making it a viable sustainable alternative for packaging and medical applications. The crystalline structure of bio-based PLA enhances its rigidity and dimensional stability, while fossil-based PLA may demonstrate slightly higher heat resistance due to additive modifications. Both materials share similar biodegradability profiles but differ in carbon footprint, favoring bio-based PLA for eco-friendly product development.

Biodegradability and End-of-Life Options

Bio-based PLA offers enhanced biodegradability compared to fossil-based PLA, breaking down more efficiently under industrial composting conditions due to its renewable origin. Fossil-based PLA often exhibits slower degradation rates and limited end-of-life options, primarily relying on mechanical recycling or landfill disposal, which contributes to environmental persistence. Opting for bio-based PLA supports circular economy goals by enabling composting and reducing reliance on fossil resources, thereby minimizing plastic pollution and carbon footprint.

Carbon Footprint and Greenhouse Gas Emissions

Bio-based PLA significantly reduces the carbon footprint compared to fossil-based PLA by utilizing renewable resources like corn or sugarcane, leading to lower lifecycle greenhouse gas emissions. Fossil-based PLA relies on petrochemical feedstocks, resulting in higher CO2 emissions during production and end-of-life stages. Studies show bio-based PLA can cut greenhouse gas emissions by up to 60% relative to fossil-based alternatives, making it a more sustainable choice for reducing environmental impact.

Market Availability and Industry Adoption

Bio-based PLA, derived from renewable resources like corn starch, is widely available in markets aiming for sustainable alternatives, supported by increasing demand from packaging and textile industries. Fossil-based PLA, although chemically similar, relies on petrochemical feedstocks, limiting its adoption due to environmental concerns and regulatory pressures. Industry adoption heavily favors bio-based PLA due to its lower carbon footprint and biodegradability, driving innovation and expanding applications across bioplastics sectors.

Economic Considerations: Cost and Scalability

Bio-based PLA generally incurs higher production costs compared to fossil-based PLA due to raw material expenses and less mature manufacturing processes. Fossil-based PLA benefits from established supply chains and economies of scale, enabling lower prices and greater scalability. Market demand growth and technological advancements in bio-based PLA could reduce costs and improve scalability over time.

Certifications and Regulatory Standards

Bio-based PLA typically complies with international certifications such as ASTM D6400 and EN 13432, verifying its compostability and biodegradability under industrial composting conditions. Fossil-based PLA, while chemically similar, often lacks such certification due to reliance on petrochemical feedstocks and different production standards. Regulatory frameworks like the European Union's Packaging and Packaging Waste Directive emphasize the importance of certified bioplastics to support environmental sustainability and waste management goals.

Future Prospects of PLA in Sustainable Packaging

Bio-Based PLA offers a significant reduction in carbon footprint compared to fossil-based PLA, enhancing its appeal for sustainable packaging solutions. Advancements in fermentation technology and feedstock diversity are driving down production costs, increasing the scalability of PLA. As regulations tighten on single-use plastics, the demand for fully biodegradable and bio-based PLA materials is projected to rise sharply, positioning PLA as a leading sustainable packaging alternative.

Bio-Based PLA vs Fossil-Based PLA Infographic

materialdif.com

materialdif.com