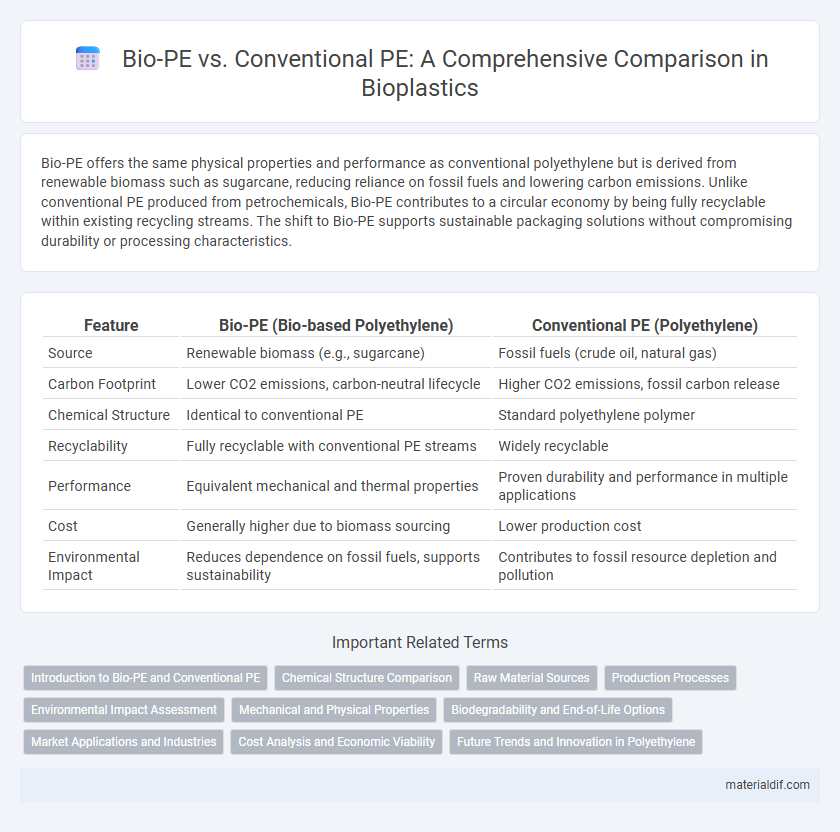

Bio-PE offers the same physical properties and performance as conventional polyethylene but is derived from renewable biomass such as sugarcane, reducing reliance on fossil fuels and lowering carbon emissions. Unlike conventional PE produced from petrochemicals, Bio-PE contributes to a circular economy by being fully recyclable within existing recycling streams. The shift to Bio-PE supports sustainable packaging solutions without compromising durability or processing characteristics.

Table of Comparison

| Feature | Bio-PE (Bio-based Polyethylene) | Conventional PE (Polyethylene) |

|---|---|---|

| Source | Renewable biomass (e.g., sugarcane) | Fossil fuels (crude oil, natural gas) |

| Carbon Footprint | Lower CO2 emissions, carbon-neutral lifecycle | Higher CO2 emissions, fossil carbon release |

| Chemical Structure | Identical to conventional PE | Standard polyethylene polymer |

| Recyclability | Fully recyclable with conventional PE streams | Widely recyclable |

| Performance | Equivalent mechanical and thermal properties | Proven durability and performance in multiple applications |

| Cost | Generally higher due to biomass sourcing | Lower production cost |

| Environmental Impact | Reduces dependence on fossil fuels, supports sustainability | Contributes to fossil resource depletion and pollution |

Introduction to Bio-PE and Conventional PE

Bio-PE, or bio-based polyethylene, is derived from renewable resources such as sugarcane, making it a sustainable alternative to conventional polyethylene (PE) produced from fossil fuels. Both Bio-PE and conventional PE share identical chemical structures and physical properties, enabling bio-PE to be processed using existing manufacturing technologies without modifications. The shift towards Bio-PE supports reduced carbon footprints and reliance on non-renewable resources, driving innovation in eco-friendly plastic production.

Chemical Structure Comparison

Bio-PE and conventional PE share an identical chemical structure, consisting primarily of long chains of ethylene monomers (-CH2-CH2-)n, which accounts for their similar physical and chemical properties. Both types are composed of linear polyethylene chains, but Bio-PE is derived from renewable biomass resources like sugarcane, while conventional PE is sourced from fossil fuels. This structural equivalence enables Bio-PE to be fully compatible with existing polyethylene recycling streams and applications.

Raw Material Sources

Bio-PE is derived from renewable raw materials such as sugarcane ethanol, reducing reliance on finite fossil fuels used in conventional polyethylene production. Conventional PE primarily sources its carbon from petroleum or natural gas, contributing to higher greenhouse gas emissions throughout its lifecycle. The shift to Bio-PE supports sustainable resource cycles by utilizing biomass, leading to a lower overall carbon footprint compared to fossil-based counterparts.

Production Processes

Bio-PE is produced from renewable biomass sources such as sugarcane ethanol through a fermentation process, followed by polymerization that mirrors conventional polyethylene production. Conventional PE is derived from fossil fuels, primarily ethylene obtained through the steam cracking of crude oil or natural gas. Both processes share similar polymerization techniques, but Bio-PE significantly reduces carbon footprint by replacing petrochemical feedstocks with bio-based alternatives.

Environmental Impact Assessment

Bio-PE (bio-based polyethylene) significantly reduces carbon footprint by utilizing renewable biomass feedstocks, leading to lower greenhouse gas emissions compared to conventional PE derived from fossil fuels. Life Cycle Assessment (LCA) studies highlight that Bio-PE decreases fossil resource depletion and mitigates climate change impacts, while maintaining comparable performance and recyclability. However, sustainable sourcing and land use management remain critical factors in maximizing the environmental benefits of Bio-PE production.

Mechanical and Physical Properties

Bio-PE (bio-based polyethylene) exhibits mechanical and physical properties nearly identical to conventional PE, including tensile strength, impact resistance, and flexibility, making it suitable for the same applications. Both materials demonstrate similar melting points around 130degC and comparable density ranges between 0.91 and 0.96 g/cm3, ensuring consistent performance in packaging, films, and containers. The key advantage of Bio-PE lies in its renewable feedstock origin, while maintaining the durability and processability standards expected from traditional polyethylene.

Biodegradability and End-of-Life Options

Bio-PE (bio-based polyethylene) shares the same chemical structure as conventional PE, resulting in similar non-biodegradable properties and limited biodegradability in natural environments. End-of-life options for Bio-PE primarily include mechanical recycling and energy recovery, analogous to conventional PE, but it offers the advantage of being sourced from renewable resources. Composting or biodegradation are not effective disposal methods for either type, emphasizing the need for established recycling infrastructure to manage their environmental impact.

Market Applications and Industries

Bio-PE, derived from renewable resources like sugarcane, is widely adopted in packaging, agriculture, and consumer goods industries, offering a sustainable alternative to conventional PE. Conventional PE, produced from petrochemicals, remains dominant in automotive, construction, and heavy-duty packaging sectors due to its established supply chain and cost efficiency. Growing environmental regulations and consumer demand are driving increased Bio-PE usage, especially in flexible packaging and single-use products, aiming to reduce carbon footprint and fossil fuel dependency.

Cost Analysis and Economic Viability

Bio-PE, derived from renewable resources like sugarcane, generally incurs higher production costs compared to conventional PE made from fossil fuels due to raw material expenses and limited large-scale manufacturing facilities. Despite the initial cost premium, Bio-PE offers long-term economic viability through regulatory incentives, carbon credits, and growing consumer demand for sustainable materials, which can offset higher prices. Cost reductions are anticipated as technological advancements and economies of scale improve, narrowing the price gap between Bio-PE and conventional PE.

Future Trends and Innovation in Polyethylene

Bio-PE, derived from renewable resources like sugarcane, offers a lower carbon footprint compared to conventional PE made from fossil fuels. Emerging innovations in polyethylene focus on enhancing biodegradability and incorporating bio-based additives to improve performance and sustainability. Future trends emphasize scaling bio-PE production through advanced biorefineries and integrating circular economy principles to reduce plastic waste.

Bio-PE vs Conventional PE Infographic

materialdif.com

materialdif.com