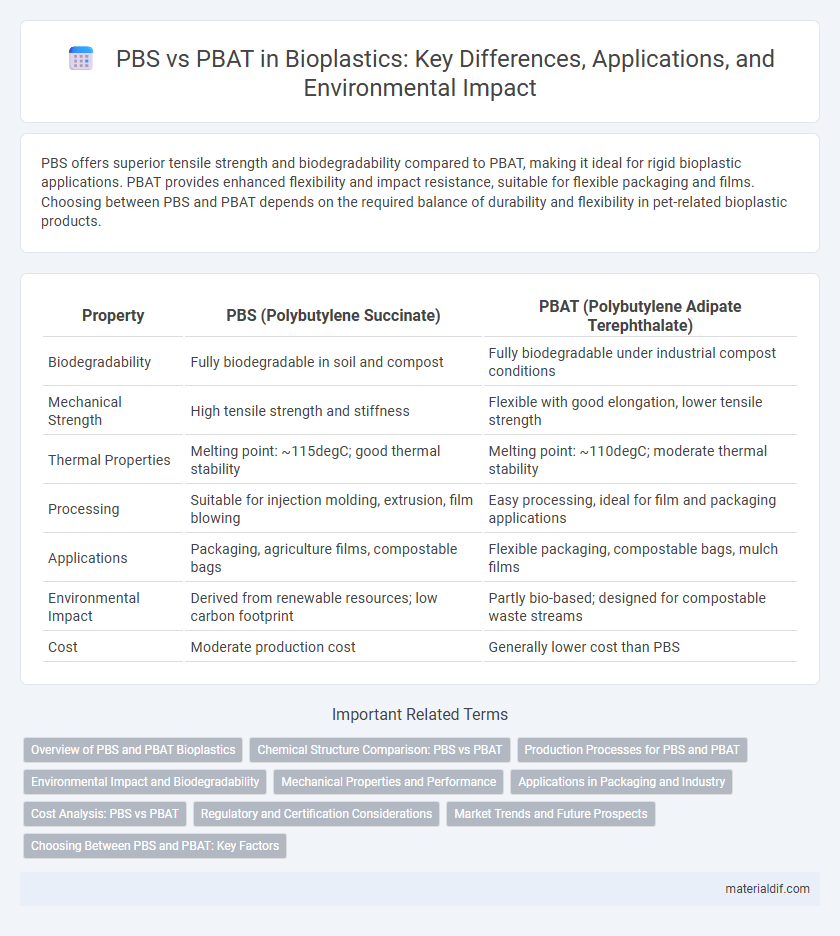

PBS offers superior tensile strength and biodegradability compared to PBAT, making it ideal for rigid bioplastic applications. PBAT provides enhanced flexibility and impact resistance, suitable for flexible packaging and films. Choosing between PBS and PBAT depends on the required balance of durability and flexibility in pet-related bioplastic products.

Table of Comparison

| Property | PBS (Polybutylene Succinate) | PBAT (Polybutylene Adipate Terephthalate) |

|---|---|---|

| Biodegradability | Fully biodegradable in soil and compost | Fully biodegradable under industrial compost conditions |

| Mechanical Strength | High tensile strength and stiffness | Flexible with good elongation, lower tensile strength |

| Thermal Properties | Melting point: ~115degC; good thermal stability | Melting point: ~110degC; moderate thermal stability |

| Processing | Suitable for injection molding, extrusion, film blowing | Easy processing, ideal for film and packaging applications |

| Applications | Packaging, agriculture films, compostable bags | Flexible packaging, compostable bags, mulch films |

| Environmental Impact | Derived from renewable resources; low carbon footprint | Partly bio-based; designed for compostable waste streams |

| Cost | Moderate production cost | Generally lower cost than PBS |

Overview of PBS and PBAT Bioplastics

PBS (Polybutylene Succinate) is a biodegradable aliphatic polyester derived from renewable resources, known for its high crystallinity, excellent mechanical strength, and thermal stability, making it suitable for packaging, agricultural films, and disposable products. PBAT (Polybutylene Adipate Terephthalate) is a biodegradable copolyester synthesized from adipic acid, terephthalic acid, and 1,4-butanediol, characterized by its flexibility, elasticity, and good processability, widely used in compostable bags and flexible packaging. Both PBS and PBAT are compostable bioplastics with different mechanical and thermal properties that target sustainability in various industrial applications.

Chemical Structure Comparison: PBS vs PBAT

PBS (Polybutylene Succinate) features a linear aliphatic polyester structure derived from succinic acid and 1,4-butanediol, resulting in high crystallinity and thermal stability. PBAT (Polybutylene Adipate Terephthalate) is a copolyester combining aliphatic adipic acid and aromatic terephthalic acid units, providing enhanced flexibility and biodegradability due to its semi-aromatic composition. The key chemical difference lies in PBAT's inclusion of aromatic terephthalate segments, which influence its mechanical properties and degradation profile compared to the fully aliphatic PBS.

Production Processes for PBS and PBAT

PBS (Polybutylene Succinate) is produced through the polycondensation of succinic acid with 1,4-butanediol, often sourced from renewable feedstocks, using catalysts that promote high molecular weight polymer formation. PBAT (Polybutylene Adipate Terephthalate) synthesis involves a two-step polycondensation process combining adipic acid, terephthalic acid or its dimethyl ester, and 1,4-butanediol, creating a copolyester with enhanced flexibility and biodegradability. Both production processes require precise temperature control and catalyst systems to optimize polymer chain length, crystallinity, and mechanical properties for diverse biodegradable applications.

Environmental Impact and Biodegradability

PBS (Polybutylene Succinate) and PBAT (Polybutylene Adipate Terephthalate) are both biodegradable bioplastics, but PBS is derived from renewable resources like sugarcane, offering a lower carbon footprint compared to PBAT, which is partially petroleum-based. Biodegradability rates of PBS are higher in industrial composting conditions, breaking down into water, carbon dioxide, and biomass more efficiently than PBAT. PBAT, while flexible and compatible with other bioplastics, tends to degrade slower in natural environments, potentially leading to longer persistence in soil and marine ecosystems.

Mechanical Properties and Performance

PBS (Polybutylene Succinate) exhibits higher tensile strength and stiffness compared to PBAT (Polybutylene Adipate Terephthalate), making it suitable for rigid biodegradable packaging. PBAT offers superior flexibility and elongation at break, enhancing its performance in applications requiring high impact resistance and ductility. The blend of PBS and PBAT often results in balanced mechanical properties, combining rigidity with flexibility for diverse biodegradable product uses.

Applications in Packaging and Industry

PBS (Polybutylene Succinate) offers excellent mechanical strength and thermal stability, making it ideal for rigid packaging and agricultural films where durability is critical. PBAT (Polybutylene Adipate Terephthalate) excels in flexibility and biodegradability, commonly used for soft packaging applications such as bags and compostable liners. Both bioplastics serve complementary roles in packaging and industry by combining sustainability with performance tailored to specific product requirements.

Cost Analysis: PBS vs PBAT

PBS (Polybutylene Succinate) generally offers a more cost-effective solution compared to PBAT (Polybutylene Adipate Terephthalate) due to its lower raw material prices and simpler production processes. PBAT typically incurs higher manufacturing costs as it blends aromatic and aliphatic components to enhance flexibility, which increases complexity and price. Cost analysis shows that PBS is preferred for bulk applications requiring biodegradability at a minimal cost, while PBAT is chosen when flexibility justifies the higher expenditure.

Regulatory and Certification Considerations

PBS (Polybutylene Succinate) and PBAT (Polybutylene Adipate Terephthalate) differ in regulatory approval and certification pathways with PBS often preferred for its biodegradability compliance under standards like ASTM D6400 and EN 13432. PBAT, while flexible and used in compostable blends, may face stricter scrutiny regarding additives and recycling codes in markets like the EU and US. Certifications such as OK Compost and Seedling are critical benchmarks influencing the selection of PBS or PBAT in eco-friendly packaging and product design.

Market Trends and Future Prospects

PBS and PBAT are gaining significant traction in the biodegradable plastics market due to increasing demand for sustainable packaging and agricultural films. PBS offers superior thermal stability and mechanical strength, positioning it well for applications requiring durability, while PBAT excels in flexibility and compostability, driving its adoption in single-use products. Market forecasts predict a compound annual growth rate (CAGR) exceeding 12% for both polymers through 2030, fueled by regulatory pressures and consumer preference for eco-friendly alternatives.

Choosing Between PBS and PBAT: Key Factors

Choosing between PBS (Polybutylene Succinate) and PBAT (Polybutylene Adipate Terephthalate) depends on factors like biodegradability rate, mechanical properties, and application requirements. PBS offers higher rigidity and thermal resistance, making it suitable for packaging and agricultural films, while PBAT provides greater flexibility and elongation, ideal for compostable bags and mulch films. Cost-effectiveness and compatibility with existing production processes also influence the decision in bioplastic applications.

PBS vs PBAT Infographic

materialdif.com

materialdif.com