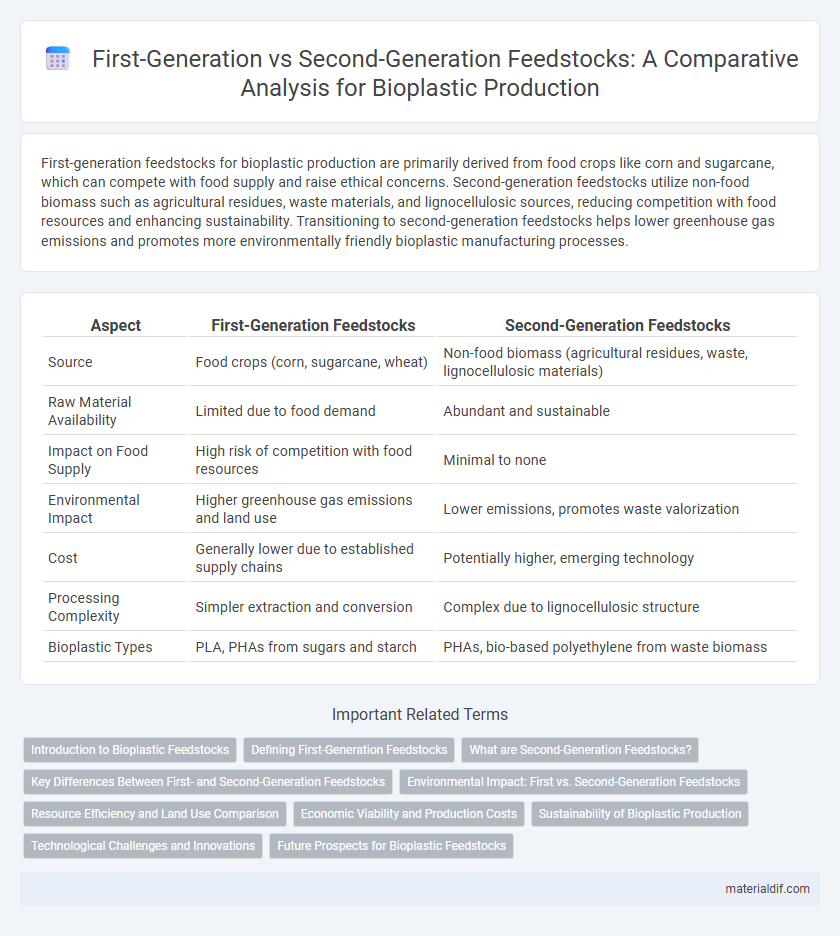

First-generation feedstocks for bioplastic production are primarily derived from food crops like corn and sugarcane, which can compete with food supply and raise ethical concerns. Second-generation feedstocks utilize non-food biomass such as agricultural residues, waste materials, and lignocellulosic sources, reducing competition with food resources and enhancing sustainability. Transitioning to second-generation feedstocks helps lower greenhouse gas emissions and promotes more environmentally friendly bioplastic manufacturing processes.

Table of Comparison

| Aspect | First-Generation Feedstocks | Second-Generation Feedstocks |

|---|---|---|

| Source | Food crops (corn, sugarcane, wheat) | Non-food biomass (agricultural residues, waste, lignocellulosic materials) |

| Raw Material Availability | Limited due to food demand | Abundant and sustainable |

| Impact on Food Supply | High risk of competition with food resources | Minimal to none |

| Environmental Impact | Higher greenhouse gas emissions and land use | Lower emissions, promotes waste valorization |

| Cost | Generally lower due to established supply chains | Potentially higher, emerging technology |

| Processing Complexity | Simpler extraction and conversion | Complex due to lignocellulosic structure |

| Bioplastic Types | PLA, PHAs from sugars and starch | PHAs, bio-based polyethylene from waste biomass |

Introduction to Bioplastic Feedstocks

First-generation bioplastic feedstocks primarily consist of food crops such as corn, sugarcane, and wheat, which are rich in starch and sugars ideal for fermentation processes. Second-generation feedstocks utilize non-food biomass like agricultural residues, lignocellulosic materials, and industrial waste, offering a more sustainable alternative by minimizing competition with food resources. The shift from first- to second-generation feedstocks enhances bioplastic production efficiency while reducing environmental impacts and promoting circular bioeconomy principles.

Defining First-Generation Feedstocks

First-generation feedstocks for bioplastic production primarily consist of edible crops such as corn, sugarcane, and wheat, which are rich in starches and sugars that can be easily fermented into biopolymers like polylactic acid (PLA). These feedstocks are characterized by high carbohydrate content, enabling efficient conversion into bio-based materials but raising concerns about food security and land use competition. Understanding the reliance on first-generation feedstocks is crucial for assessing the sustainability and scalability of current bioplastic manufacturing processes.

What are Second-Generation Feedstocks?

Second-generation feedstocks for bioplastic production are derived from non-food biomass, such as agricultural residues, forestry waste, and non-edible plants, minimizing competition with food supplies. These feedstocks offer enhanced sustainability by utilizing lignocellulosic materials, which require advanced enzymatic or chemical processes to break down complex carbohydrates into fermentable sugars for biopolymer synthesis. Second-generation feedstocks present a promising solution for reducing environmental impact and improving resource efficiency in the bioplastics industry.

Key Differences Between First- and Second-Generation Feedstocks

First-generation feedstocks for bioplastics are primarily derived from food crops such as corn, sugarcane, and wheat, which directly compete with food supply and agricultural land use. Second-generation feedstocks utilize non-food biomass including agricultural residues, lignocellulosic materials, and waste biomass, significantly reducing competition with food resources and promoting sustainability. Key differences include resource competition, environmental impact, and feedstock availability, with second-generation feedstocks offering greater potential for circular economy integration and carbon footprint reduction.

Environmental Impact: First vs. Second-Generation Feedstocks

First-generation feedstocks, derived from food crops like corn and sugarcane, often lead to competition with food supply and contribute to deforestation and high water usage. Second-generation feedstocks utilize non-food biomass such as agricultural residues and lignocellulosic materials, significantly reducing land use and greenhouse gas emissions. This shift enhances sustainability by lowering the environmental footprint associated with bioplastic production.

Resource Efficiency and Land Use Comparison

First-generation feedstocks for bioplastic production, derived from food crops like corn and sugarcane, often require significant arable land and water resources, leading to competition with food supply and increased environmental impact. In contrast, second-generation feedstocks utilize non-food biomass such as agricultural residues and woody plants, promoting higher resource efficiency by leveraging waste materials and marginal lands unsuitable for food production. This shift reduces land use pressure and enhances the sustainability of bioplastic production by minimizing the reliance on prime agricultural resources.

Economic Viability and Production Costs

First-generation feedstocks, derived from food crops like corn and sugarcane, typically offer lower production costs due to established agricultural practices and supply chains, but compete directly with food markets, impacting economic viability. Second-generation feedstocks utilize non-food biomass such as agricultural residues and lignocellulosic materials, presenting higher initial processing costs but enhanced sustainability and reduced competition with food resources. Economic viability of second-generation bioplastics improves as technological advancements lower conversion costs and increase feedstock availability, potentially offering a more cost-effective solution in the long term.

Sustainability of Bioplastic Production

First-generation feedstocks, derived from food crops such as corn and sugarcane, pose sustainability challenges due to competition with food supply and extensive land use. Second-generation feedstocks, including agricultural residues, non-food plants, and waste biomass, offer improved sustainability by utilizing renewable resources without impacting food security. Incorporating second-generation materials enhances bioplastic production's environmental benefits through reduced greenhouse gas emissions and lower land and water use.

Technological Challenges and Innovations

First-generation bioplastics rely on food crops such as corn and sugarcane, presenting challenges like competition with food supply and high land use, which limit sustainability. Second-generation feedstocks utilize non-food biomass, including agricultural residues and lignocellulosic materials, requiring advanced pretreatment technologies and enzymes to efficiently convert complex polymers into fermentable sugars. Innovations in genetic engineering and process optimization enhance yield and reduce costs, enabling scalable production while addressing environmental impact and feedstock accessibility.

Future Prospects for Bioplastic Feedstocks

First-generation bioplastic feedstocks, derived from food crops like corn and sugarcane, face sustainability challenges due to competition with food supply and land use concerns. Second-generation feedstocks, sourced from non-food biomass such as agricultural residues and dedicated energy crops, offer promising future prospects by enhancing resource efficiency and reducing environmental impact. Advances in biotechnology and feedstock processing are driving increased commercialization and diversification of bioplastic materials from sustainable second-generation sources.

First-generation feedstocks vs Second-generation feedstocks Infographic

materialdif.com

materialdif.com