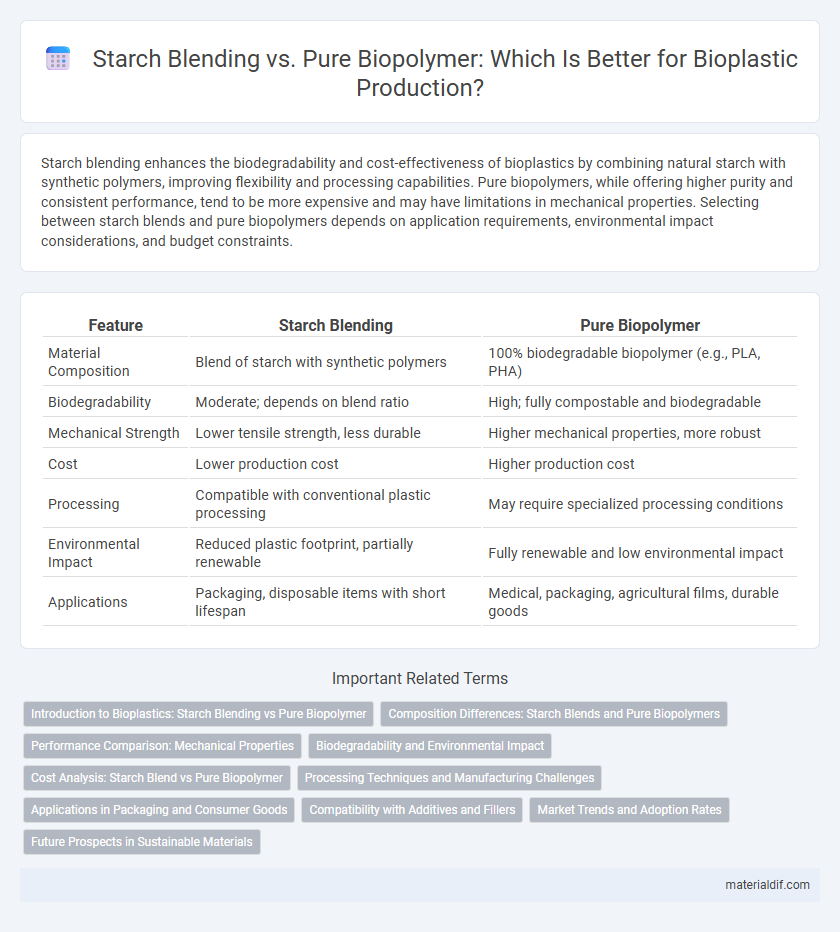

Starch blending enhances the biodegradability and cost-effectiveness of bioplastics by combining natural starch with synthetic polymers, improving flexibility and processing capabilities. Pure biopolymers, while offering higher purity and consistent performance, tend to be more expensive and may have limitations in mechanical properties. Selecting between starch blends and pure biopolymers depends on application requirements, environmental impact considerations, and budget constraints.

Table of Comparison

| Feature | Starch Blending | Pure Biopolymer |

|---|---|---|

| Material Composition | Blend of starch with synthetic polymers | 100% biodegradable biopolymer (e.g., PLA, PHA) |

| Biodegradability | Moderate; depends on blend ratio | High; fully compostable and biodegradable |

| Mechanical Strength | Lower tensile strength, less durable | Higher mechanical properties, more robust |

| Cost | Lower production cost | Higher production cost |

| Processing | Compatible with conventional plastic processing | May require specialized processing conditions |

| Environmental Impact | Reduced plastic footprint, partially renewable | Fully renewable and low environmental impact |

| Applications | Packaging, disposable items with short lifespan | Medical, packaging, agricultural films, durable goods |

Introduction to Bioplastics: Starch Blending vs Pure Biopolymer

Starch blending in bioplastics enhances biodegradability and reduces production costs by combining natural starch with synthetic polymers, balancing performance and sustainability. Pure biopolymers, derived entirely from renewable biomass such as polylactic acid (PLA) or polyhydroxyalkanoates (PHA), offer higher purity and consistent biodegradation rates but often come with higher manufacturing expenses. Selecting between starch blends and pure biopolymers depends on the desired material properties, environmental impact goals, and economic considerations in bioplastic applications.

Composition Differences: Starch Blends and Pure Biopolymers

Starch blends typically combine natural starch with synthetic or biodegradable polymers, enhancing mechanical strength and moisture resistance compared to pure biopolymers. Pure biopolymers, such as polylactic acid (PLA) or polyhydroxyalkanoates (PHA), consist solely of polymer chains derived from renewable sources, providing inherent biodegradability and compostability. The compositional variation directly influences processing characteristics, performance metrics, and environmental impact of bioplastic materials.

Performance Comparison: Mechanical Properties

Starch blending with other biopolymers enhances the mechanical properties of bioplastics, offering improved tensile strength and flexibility compared to pure biopolymer formulations. Pure biopolymers often exhibit brittleness and lower impact resistance, while starch blends can be engineered to balance durability and biodegradability effectively. The resulting composite materials demonstrate better elongation at break and modulus, making them suitable for more demanding packaging and agricultural applications.

Biodegradability and Environmental Impact

Starch blending in bioplastics enhances biodegradability by introducing natural polymers that decompose more rapidly than pure biopolymers such as polylactic acid (PLA) or polyhydroxyalkanoates (PHA). Pure biopolymers often require industrial composting conditions for complete degradation, whereas starch blends can break down efficiently in both industrial and home composting environments, reducing environmental persistence and microplastic formation. The environmental impact of starch-blended bioplastics is generally lower due to reduced reliance on synthetic additives and improved end-of-life disposal options, promoting a more sustainable lifecycle compared to pure biopolymer alternatives.

Cost Analysis: Starch Blend vs Pure Biopolymer

Starch blends offer a significant cost advantage over pure biopolymers due to lower raw material expenses and easier processing techniques. Pure biopolymers, while providing superior biodegradability and mechanical properties, incur higher production costs linked to fermentation or extraction processes. The economic feasibility of starch blends makes them a preferred choice for large-scale applications despite some compromise in material performance.

Processing Techniques and Manufacturing Challenges

Starch blending involves combining starch with other biopolymers or synthetic polymers to enhance material properties and processability, often requiring extrusion, injection molding, or compression molding techniques adapted for moisture sensitivity and thermal stability. Pure biopolymers such as polylactic acid (PLA) demand precise temperature control during processing to prevent degradation and maintain mechanical strength, with challenges including brittleness and slow crystallization rates. Both approaches face manufacturing challenges like inconsistent raw material quality, moisture sensitivity, and the need for specialized equipment to optimize drying and thermal processing parameters.

Applications in Packaging and Consumer Goods

Starch blending in bioplastics enhances flexibility and cost-effectiveness, making it ideal for packaging films, bags, and disposable consumer goods where moderate durability is sufficient. Pure biopolymers like PLA and PHA offer superior mechanical strength and clarity, preferred for rigid packaging, food containers, and reusable consumer products requiring higher performance. Balancing starch blends with pure biopolymers optimizes biodegradability and product functionality in diverse packaging and consumer applications.

Compatibility with Additives and Fillers

Starch blending with biopolymers improves compatibility with additives and fillers by enhancing dispersion and interfacial adhesion, leading to better mechanical properties and processability. Pure biopolymers often exhibit limited compatibility due to their distinct molecular structures, which can cause phase separation and reduced effectiveness of additives. Incorporating starch acts as a natural compatibilizer, optimizing composite performance and expanding application potential in bioplastic formulations.

Market Trends and Adoption Rates

Starch blending remains a dominant practice in the bioplastic industry due to its cost-effectiveness and improved biodegradability, driving faster adoption in packaging and disposable products. Pure biopolymers like PLA and PHA exhibit superior material properties but face slower market penetration because of higher production costs and supply chain limitations. Market trends indicate escalating demand for sustainable alternatives, with starch blends capturing significant share in emerging economies, while developed markets gradually shift toward pure biopolymers for performance-critical applications.

Future Prospects in Sustainable Materials

Starch blending enhances bioplastic versatility by improving biodegradability and cost-efficiency compared to pure biopolymers such as polylactic acid (PLA) or polyhydroxyalkanoates (PHA). Emerging advancements in nanocomposites and enzymatic modification further optimize starch-based blends for industrial scalability and environmental impact reduction. Future prospects highlight starch blends as pivotal in sustainable materials, balancing performance with ecological benefits in packaging, agriculture, and biomedical applications.

Starch Blending vs Pure Biopolymer Infographic

materialdif.com

materialdif.com