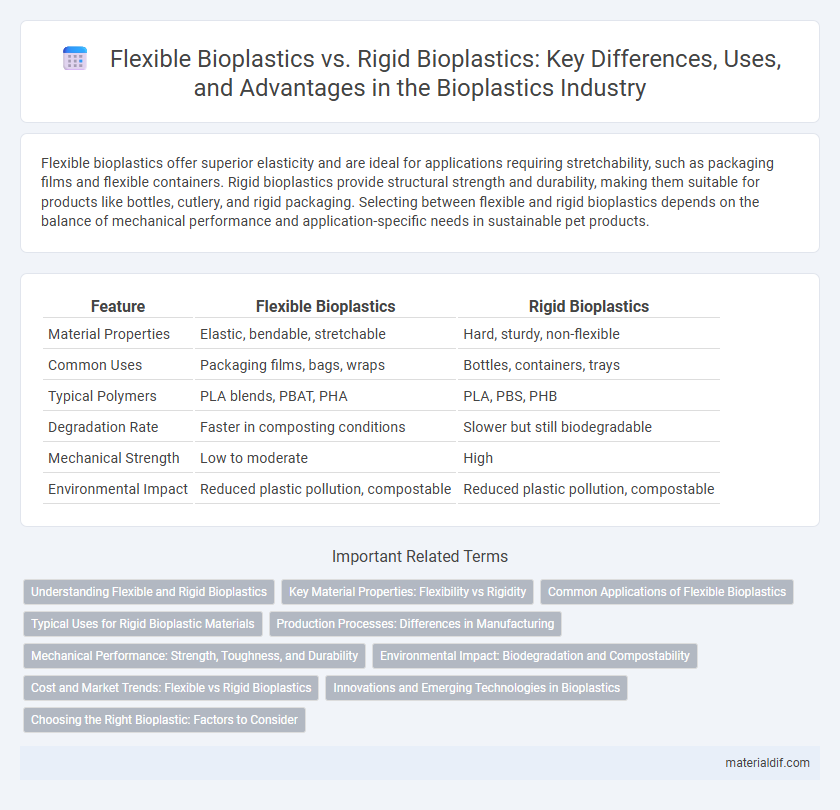

Flexible bioplastics offer superior elasticity and are ideal for applications requiring stretchability, such as packaging films and flexible containers. Rigid bioplastics provide structural strength and durability, making them suitable for products like bottles, cutlery, and rigid packaging. Selecting between flexible and rigid bioplastics depends on the balance of mechanical performance and application-specific needs in sustainable pet products.

Table of Comparison

| Feature | Flexible Bioplastics | Rigid Bioplastics |

|---|---|---|

| Material Properties | Elastic, bendable, stretchable | Hard, sturdy, non-flexible |

| Common Uses | Packaging films, bags, wraps | Bottles, containers, trays |

| Typical Polymers | PLA blends, PBAT, PHA | PLA, PBS, PHB |

| Degradation Rate | Faster in composting conditions | Slower but still biodegradable |

| Mechanical Strength | Low to moderate | High |

| Environmental Impact | Reduced plastic pollution, compostable | Reduced plastic pollution, compostable |

Understanding Flexible and Rigid Bioplastics

Flexible bioplastics, such as polylactic acid (PLA) and thermoplastic starch, exhibit elasticity and durability ideal for packaging films and disposable gloves. Rigid bioplastics, like polyhydroxyalkanoates (PHA) and bio-based polyethylene, provide structural strength suited for containers, cutlery, and automotive parts. Understanding the mechanical properties and biodegradability of these categories enables targeted applications that balance environmental impact with performance demands.

Key Material Properties: Flexibility vs Rigidity

Flexible bioplastics, such as thermoplastic starch and polyhydroxyalkanoates, exhibit high elongation at break and excellent impact resistance, making them ideal for applications requiring bendability and stretchability. Rigid bioplastics like polylactic acid (PLA) and bio-based polyethylene terephthalate (PET) demonstrate superior tensile strength and dimensional stability, suitable for structural components and packaging that demand firmness. Understanding the mechanical properties, including modulus of elasticity and tensile strength, is critical for selecting the appropriate bioplastic type based on flexibility versus rigidity requirements.

Common Applications of Flexible Bioplastics

Flexible bioplastics are widely used in food packaging, agricultural films, and medical devices due to their elasticity and durability. Their ability to biodegrade while maintaining flexibility makes them ideal for applications requiring stretchability and impact resistance. Common materials include polyhydroxyalkanoates (PHA) and starch-based bioplastics, which provide sustainable alternatives to traditional plastics in flexible formats.

Typical Uses for Rigid Bioplastic Materials

Rigid bioplastics are commonly utilized in applications requiring structural integrity and durability, such as packaging containers, agricultural trays, and automotive interior components. These materials offer excellent impact resistance and dimensional stability, making them ideal for products like rigid bottles, cutlery, and electronic housings. Their ability to maintain shape under stress distinguishes them from flexible bioplastics used primarily in films and wraps.

Production Processes: Differences in Manufacturing

Flexible bioplastics are produced using extrusion and blown film processes, allowing polymers to be stretched and shaped into thin, pliable films suitable for packaging and bags. Rigid bioplastics involve injection molding or thermoforming, where polymers are heated and molded into firm, durable shapes like containers and utensils. The manufacturing differences impact material properties, with flexible bioplastics prioritizing elasticity and rigidity focusing on structural integrity.

Mechanical Performance: Strength, Toughness, and Durability

Flexible bioplastics exhibit superior toughness and elongation, making them ideal for applications requiring impact resistance and flexibility, such as packaging films and soft containers. Rigid bioplastics demonstrate higher tensile strength and stiffness, ensuring durability and structural integrity in products like cutlery and casings. Mechanical performance in bioplastics is critically influenced by polymer composition and processing methods, which tailor the balance between strength, toughness, and durability based on specific application needs.

Environmental Impact: Biodegradation and Compostability

Flexible bioplastics, such as those made from PLA or PHA, typically exhibit faster biodegradation rates in industrial composting facilities due to their thinner structure and higher surface area. Rigid bioplastics often require extended timeframes for complete compostability, influenced by their denser polymer matrix and additives. Both types contribute to reducing plastic pollution but demand proper waste management to optimize environmental benefits and enhance soil health through effective biodegradation.

Cost and Market Trends: Flexible vs Rigid Bioplastics

Flexible bioplastics generally cost less to produce due to lower raw material density and simpler processing techniques, driving higher demand in packaging and disposable goods markets. Rigid bioplastics, while more expensive, are favored in automotive and electronics applications where durability and structural integrity are critical. Market trends indicate a surge in flexible bioplastics driven by consumer preference for sustainable, lightweight alternatives, whereas rigid bioplastics growth is steady, supported by industry regulations promoting eco-friendly materials.

Innovations and Emerging Technologies in Bioplastics

Flexible bioplastics incorporate innovations such as enhanced polymer blends and bio-based plasticizers, improving elasticity and durability for packaging and wearable applications. Rigid bioplastics benefit from emerging technologies like microbial fermentation and advanced additives, which increase strength and thermal resistance in automotive and construction materials. Both types leverage bioengineering and nanotechnology to optimize biodegradability and mechanical performance, driving sustainable solutions in diverse industries.

Choosing the Right Bioplastic: Factors to Consider

Choosing the right bioplastic involves assessing factors like application requirements, mechanical properties, and environmental impact. Flexible bioplastics offer elasticity and are ideal for packaging and films, while rigid bioplastics provide strength and durability for items like containers and automotive parts. Biodegradability, production cost, and compatibility with existing manufacturing processes also influence the selection between flexible and rigid bioplastics.

Flexible Bioplastics vs Rigid Bioplastics Infographic

materialdif.com

materialdif.com