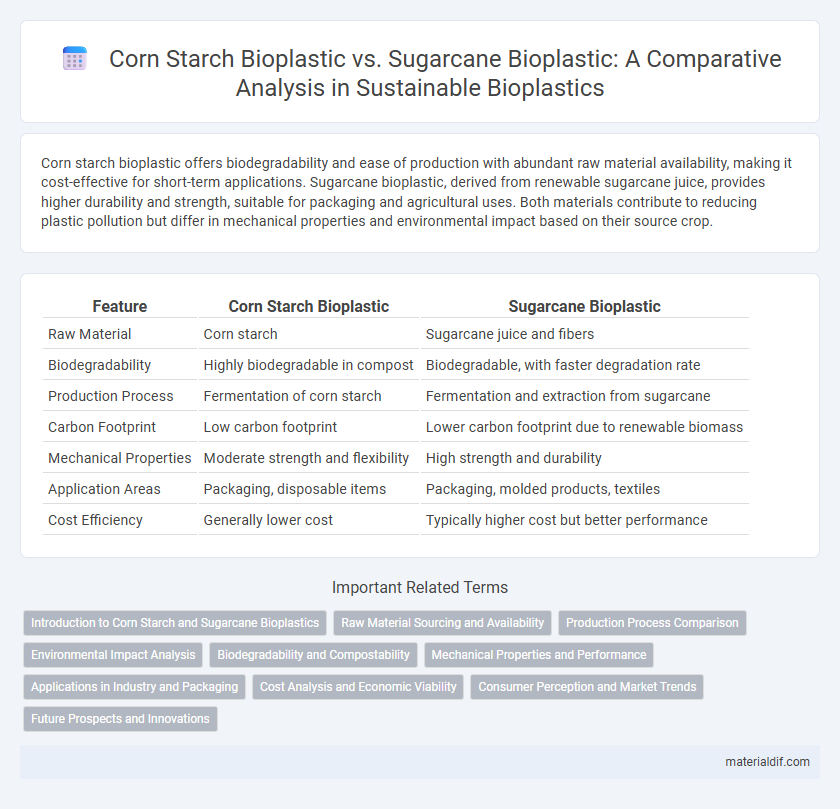

Corn starch bioplastic offers biodegradability and ease of production with abundant raw material availability, making it cost-effective for short-term applications. Sugarcane bioplastic, derived from renewable sugarcane juice, provides higher durability and strength, suitable for packaging and agricultural uses. Both materials contribute to reducing plastic pollution but differ in mechanical properties and environmental impact based on their source crop.

Table of Comparison

| Feature | Corn Starch Bioplastic | Sugarcane Bioplastic |

|---|---|---|

| Raw Material | Corn starch | Sugarcane juice and fibers |

| Biodegradability | Highly biodegradable in compost | Biodegradable, with faster degradation rate |

| Production Process | Fermentation of corn starch | Fermentation and extraction from sugarcane |

| Carbon Footprint | Low carbon footprint | Lower carbon footprint due to renewable biomass |

| Mechanical Properties | Moderate strength and flexibility | High strength and durability |

| Application Areas | Packaging, disposable items | Packaging, molded products, textiles |

| Cost Efficiency | Generally lower cost | Typically higher cost but better performance |

Introduction to Corn Starch and Sugarcane Bioplastics

Corn starch bioplastic is derived from abundant, renewable corn resources, offering biodegradability and compostability as key environmental benefits. Sugarcane bioplastic, primarily produced through fermentation of sugarcane ethanol, provides a sustainable alternative with lower carbon footprint and high mechanical strength. Both bioplastics serve as eco-friendly substitutes to conventional plastics, leveraging plant-based raw materials to reduce reliance on fossil fuels.

Raw Material Sourcing and Availability

Corn starch bioplastic relies on corn, predominantly sourced from major agricultural regions like the United States and China, benefiting from well-established farming infrastructure and high global production volumes. Sugarcane bioplastic is derived from sugarcane, primarily grown in Brazil, India, and Southeast Asia, offering renewable and rapidly renewable raw materials with high photosynthetic efficiency. Availability of sugarcane biomass is often seasonal but abundant in tropical climates, while corn starch presents a more consistent supply year-round from temperate zones.

Production Process Comparison

Corn starch bioplastic production involves extracting starch from corn kernels, followed by gelatinization, plasticization with additives like glycerol, and molding under heat and pressure. Sugarcane bioplastic, primarily polylactic acid (PLA), is produced by fermenting sugarcane-derived glucose into lactic acid, which is then polymerized through condensation or ring-opening polymerization. The corn starch method relies on mechanical and thermal processing of polysaccharides, whereas sugarcane bioplastic involves biochemical fermentation and polymerization, resulting in distinct energy and resource inputs.

Environmental Impact Analysis

Corn starch bioplastic and sugarcane bioplastic differ in their environmental impacts primarily due to the agricultural practices and resource inputs associated with each crop. Corn starch bioplastic production often requires higher fertilizer and pesticide use, leading to increased soil degradation and greenhouse gas emissions compared to sugarcane bioplastic, which benefits from more efficient photosynthesis and higher biomass yield per hectare. Life cycle assessment studies indicate that sugarcane bioplastic generally results in lower carbon footprints and better water use efficiency, making it a more sustainable option in terms of environmental impact.

Biodegradability and Compostability

Corn starch bioplastic exhibits high biodegradability due to its polysaccharide structure, breaking down efficiently in industrial composting conditions within 90 to 120 days. Sugarcane bioplastic, often derived from bagasse, offers similar compostability but tends to decompose faster in both industrial and home composting environments, typically within 60 to 90 days. Both bioplastics contribute significantly to reducing plastic pollution, yet sugarcane bioplastic's accelerated compostability makes it a preferable choice for eco-friendly waste management.

Mechanical Properties and Performance

Corn starch bioplastic exhibits lower tensile strength and elongation at break compared to sugarcane bioplastic, which offers enhanced flexibility and durability. Sugarcane bioplastic typically demonstrates superior impact resistance and water barrier properties, making it more suitable for packaging applications requiring mechanical robustness. The crystallinity and molecular structure of sugarcane bioplastics contribute to their improved mechanical performance over corn starch-based alternatives.

Applications in Industry and Packaging

Corn starch bioplastic is widely used in food packaging, disposable tableware, and agricultural films due to its biodegradability and ease of processing. Sugarcane bioplastic, often derived from bagasse, excels in durable packaging solutions, including bottles and containers, benefiting from higher mechanical strength and moisture resistance. Both materials support sustainable industrial applications, with sugarcane bioplastic favored for rigid packaging and corn starch bioplastic preferred in compostable, single-use items.

Cost Analysis and Economic Viability

Corn starch bioplastic generally incurs higher production costs due to its intensive processing requirements and reliance on genetically modified crops, impacting overall economic viability. Sugarcane bioplastic benefits from lower raw material expenses and a more efficient fermentation process, resulting in cost-effective scalability and stronger market competitiveness. Evaluating lifecycle costs and supply chain logistics reveals sugarcane-based bioplastics as more economically sustainable for large-scale manufacturing.

Consumer Perception and Market Trends

Corn starch bioplastic is often perceived by consumers as more biodegradable and environmentally friendly due to its association with staple food crops, driving strong demand in sustainable packaging markets. Sugarcane bioplastic benefits from its renewable source status and carbon-neutral production process, attracting eco-conscious consumers seeking alternatives to petroleum-based plastics. Market trends reveal a growing preference for sugarcane bioplastics in regions with robust sugarcane agriculture, while corn starch bioplastics dominate in North America due to established supply chains and government incentives.

Future Prospects and Innovations

Corn starch bioplastic and sugarcane bioplastic both present promising future prospects driven by sustainability and innovative feedstock utilization. Advances in enzymatic conversion and microbial fermentation are enhancing corn starch bioplastics' biodegradability and performance, while sugarcane bioplastics benefit from integrated biorefinery approaches that maximize carbon efficiency and reduce greenhouse gas emissions. Emerging innovations such as nanocomposite reinforcement and genetic modification of crops aim to improve mechanical properties and production scalability for both bioplastic types.

Corn starch bioplastic vs Sugarcane bioplastic Infographic

materialdif.com

materialdif.com