Industrial composting facilities provide the high temperatures and controlled conditions necessary to efficiently break down bioplastics, resulting in faster decomposition and minimal environmental impact. Home composting typically lacks the consistent heat and microbial activity required for many bioplastics, leading to slower breakdown and potential residue. Proper disposal in industrial composting systems ensures maximum biodegradability and nutrient recovery.

Table of Comparison

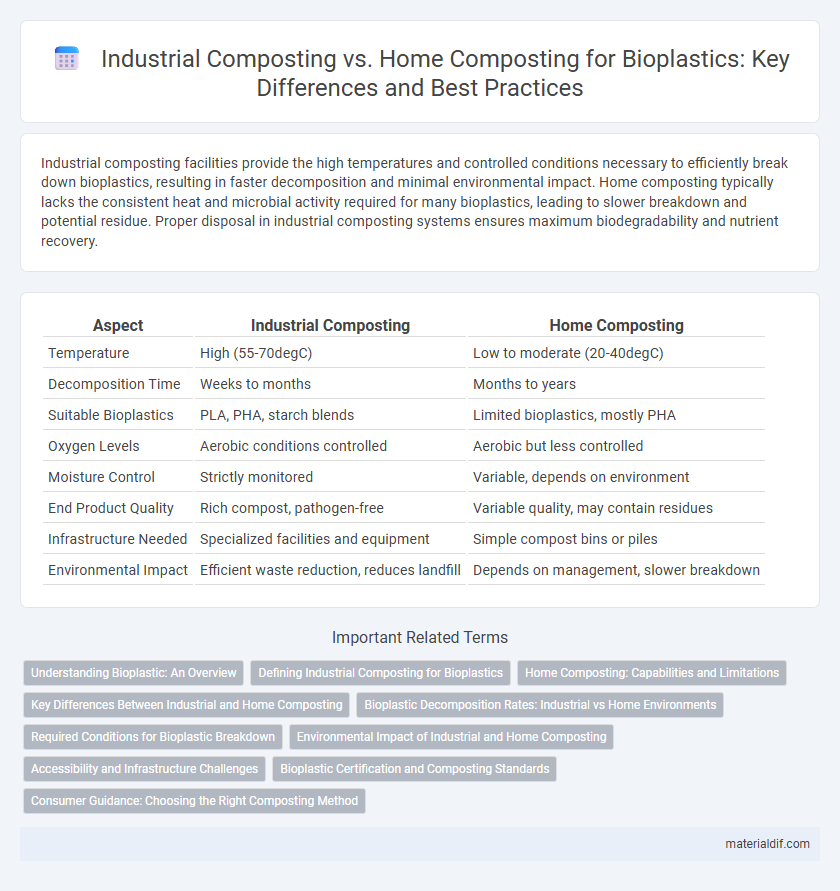

| Aspect | Industrial Composting | Home Composting |

|---|---|---|

| Temperature | High (55-70degC) | Low to moderate (20-40degC) |

| Decomposition Time | Weeks to months | Months to years |

| Suitable Bioplastics | PLA, PHA, starch blends | Limited bioplastics, mostly PHA |

| Oxygen Levels | Aerobic conditions controlled | Aerobic but less controlled |

| Moisture Control | Strictly monitored | Variable, depends on environment |

| End Product Quality | Rich compost, pathogen-free | Variable quality, may contain residues |

| Infrastructure Needed | Specialized facilities and equipment | Simple compost bins or piles |

| Environmental Impact | Efficient waste reduction, reduces landfill | Depends on management, slower breakdown |

Understanding Bioplastic: An Overview

Industrial composting facilities provide controlled conditions of temperature, humidity, and microbial activity that enable the efficient breakdown of bioplastics like PLA and PHA within weeks, a process unattainable in typical home composting environments. Home composting often lacks consistent heat and moisture levels, resulting in significantly slower bioplastic degradation and incomplete composting. Recognizing these distinctions is crucial for selecting appropriate disposal methods to ensure bioplastic materials fully biodegrade without environmental harm.

Defining Industrial Composting for Bioplastics

Industrial composting for bioplastics requires controlled conditions such as high temperatures (above 55degC), adequate humidity, and aeration to effectively break down materials like PLA and PHA within weeks. This method utilizes specialized facilities that can manage these parameters to ensure complete biodegradation, unlike home composting which operates at lower temperatures and longer timeframes. Understanding these distinctions is critical for properly disposing of bioplastics and achieving environmentally beneficial composting results.

Home Composting: Capabilities and Limitations

Home composting effectively breaks down certain bioplastics labeled as compostable, primarily those certified for home composting conditions, typically involving lower temperatures than industrial facilities. However, many bioplastics require the consistently high heat and controlled environment of industrial composting to fully decompose, making home composting inadequate for these materials. Users should verify product certifications like OK Compost HOME to ensure compatibility with home composting systems and avoid contamination in compost piles.

Key Differences Between Industrial and Home Composting

Industrial composting operates at higher temperatures, typically between 55-65degC, enabling faster and more complete breakdown of bioplastics compared to home composting, which occurs at lower temperatures around 20-30degC. The controlled environment of industrial composting facilities facilitates the biodegradation of bioplastics within weeks, while home composting may take several months and often cannot fully decompose certain bioplastic materials. Industrial composting also requires specific conditions such as aeration, moisture control, and microbial activity that are less consistent in home composting setups, influencing the efficiency and outcome of bioplastic degradation.

Bioplastic Decomposition Rates: Industrial vs Home Environments

Bioplastics decompose significantly faster in industrial composting facilities due to controlled conditions such as higher temperatures, consistent humidity, and optimized microbial activity, often breaking down within 90 to 180 days. In contrast, home composting environments exhibit lower temperatures and variable moisture, resulting in slower and incomplete decomposition of bioplastics that can extend beyond a year. The disparity in biodegradation rates emphasizes the critical role of industrial composting infrastructure for effective bioplastic waste management.

Required Conditions for Bioplastic Breakdown

Industrial composting requires controlled conditions such as high temperatures between 55-60degC, consistent humidity, and adequate oxygen levels to effectively break down bioplastics like PLA and PHA within weeks. Home composting lacks these stable conditions, often resulting in incomplete or significantly slower bioplastic decomposition due to lower temperature ranges and variable moisture. Understanding these differences is crucial for proper waste management and maximizing bioplastic biodegradability in respective composting environments.

Environmental Impact of Industrial and Home Composting

Industrial composting facilities achieve higher temperatures and controlled conditions that accelerate the biodegradation of bioplastics, significantly reducing greenhouse gas emissions compared to landfill disposal. Home composting processes occur at lower temperatures and variable conditions, often resulting in incomplete breakdown of bioplastics and potential microplastic residue, which can negatively affect soil health. Proper industrial composting not only ensures effective carbon recycling but also minimizes environmental contamination, whereas home composting may lead to inconsistent environmental benefits.

Accessibility and Infrastructure Challenges

Industrial composting facilities provide controlled conditions that accelerate bioplastic decomposition, but are limited in availability, often requiring centralized collection points that hinder widespread access. Home composting faces challenges due to lower temperatures and inconsistent moisture levels, which slow the breakdown of many bioplastics, reducing their effectiveness in typical backyard setups. Infrastructure constraints and lack of public awareness about proper sorting further complicate the integration of bioplastics into existing waste management systems.

Bioplastic Certification and Composting Standards

Industrial composting facilities meet rigorous Bioplastic certification standards such as ASTM D6400 and EN 13432, ensuring complete biodegradation within controlled temperature and humidity conditions. Home composting standards, including certifications like OK Compost HOME, require bioplastics to degrade effectively at lower temperatures typical of domestic compost systems. Choosing bioplastics certified for specific composting environments guarantees optimized breakdown and minimizes environmental impact.

Consumer Guidance: Choosing the Right Composting Method

Industrial composting facilities provide the high temperatures and controlled conditions necessary to break down many bioplastics effectively, making them the preferred option for items labeled as "industrially compostable." Home composting systems, which operate at lower temperatures and less controlled environments, often struggle to fully decompose bioplastics, especially those designed for industrial processes. Consumers should check product certifications such as ASTM D6400 or EN 13432 and local composting capabilities to select the most suitable composting method for proper bioplastic disposal.

Industrial composting vs Home composting Infographic

materialdif.com

materialdif.com