Home compostable bioplastics break down efficiently in backyard compost systems at lower temperatures, making them suitable for home disposal but often take longer to decompose. Industrial compostable bioplastics require higher temperatures and controlled conditions found in commercial composting facilities to fully degrade within a short period. Understanding the differences ensures proper disposal, reducing contamination in compost streams and enhancing waste management sustainability.

Table of Comparison

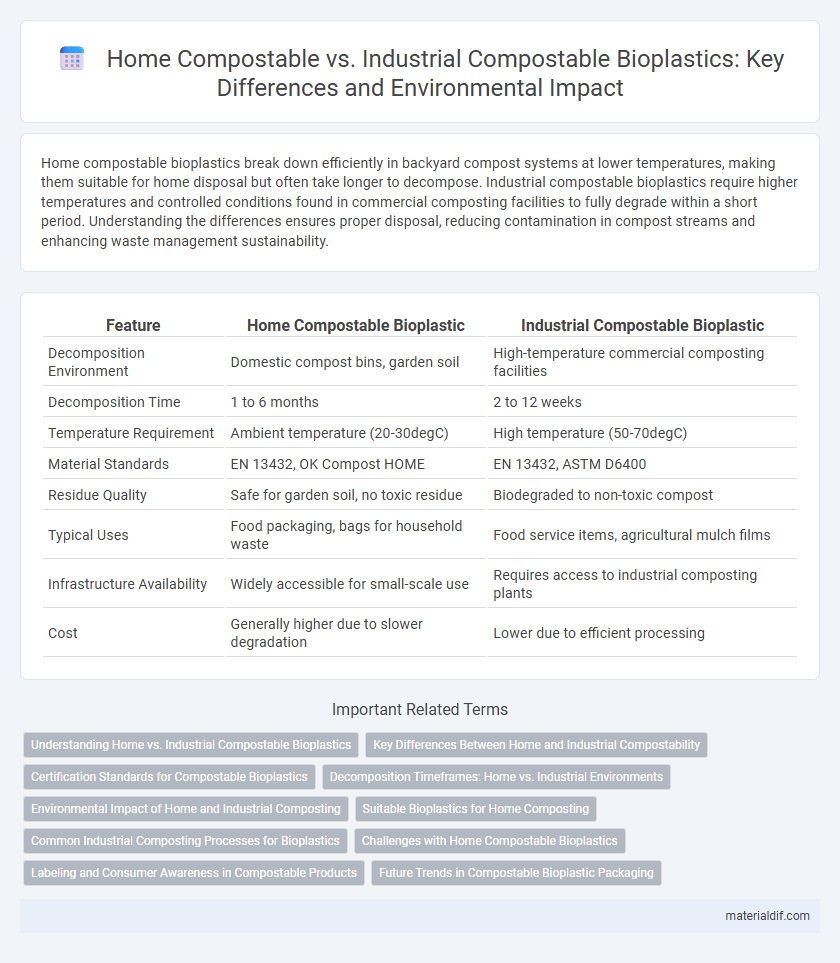

| Feature | Home Compostable Bioplastic | Industrial Compostable Bioplastic |

|---|---|---|

| Decomposition Environment | Domestic compost bins, garden soil | High-temperature commercial composting facilities |

| Decomposition Time | 1 to 6 months | 2 to 12 weeks |

| Temperature Requirement | Ambient temperature (20-30degC) | High temperature (50-70degC) |

| Material Standards | EN 13432, OK Compost HOME | EN 13432, ASTM D6400 |

| Residue Quality | Safe for garden soil, no toxic residue | Biodegraded to non-toxic compost |

| Typical Uses | Food packaging, bags for household waste | Food service items, agricultural mulch films |

| Infrastructure Availability | Widely accessible for small-scale use | Requires access to industrial composting plants |

| Cost | Generally higher due to slower degradation | Lower due to efficient processing |

Understanding Home vs. Industrial Compostable Bioplastics

Home compostable bioplastics break down effectively in typical household compost conditions within months, relying on lower temperatures and natural microbial activity. Industrial compostable bioplastics require higher temperatures, controlled humidity, and specialized microbial environments found in commercial facilities to fully decompose within a shorter timeframe. Understanding the differences ensures appropriate disposal, maximizing biodegradation and minimizing environmental impact.

Key Differences Between Home and Industrial Compostability

Home compostable bioplastics break down effectively at lower temperatures typically found in household compost bins, usually within 90 days, while industrial compostable bioplastics require higher temperatures above 55degC and controlled humidity present in commercial facilities for complete degradation. Home compostable materials often degrade into non-toxic substances that support soil health, whereas industrial composting ensures faster breakdown of more complex bioplastics, including those with additives or thicker structures. The certification standards differ, with home compostability certified by programs like ASTM D6400 for lower temperature degradation and industrial compostability adhering to ISO 17088 or EN 13432, focused on high-heat aerobic conditions.

Certification Standards for Compostable Bioplastics

Home compostable bioplastics must meet certification standards such as ASTM D6400 or EN 13432, ensuring they break down effectively in backyard composting conditions within a specific timeframe. Industrial compostable bioplastics require certifications like TUV Austria's OK Compost Industrial or ASTM D6868, which validate biodegradability under controlled, high-temperature composting facilities. Understanding these standards is crucial for choosing appropriate bioplastic products that align with available waste management systems and environmental impact goals.

Decomposition Timeframes: Home vs. Industrial Environments

Home compostable bioplastics typically break down within 90 to 180 days under ambient temperature conditions around 20-30degC, relying on natural microbial activity in gardens or backyard compost bins. Industrial compostable bioplastics decompose much faster, often within 30 to 90 days, due to higher temperatures of 50-70degC, optimized moisture, and specialized microbial populations in commercial composting facilities. Understanding these decomposition timeframes helps consumers choose the appropriate bioplastic for disposal environments, promoting effective waste management and reducing environmental impact.

Environmental Impact of Home and Industrial Composting

Home compostable bioplastics break down in typical backyard composting environments within months, reducing organic waste and lowering landfill methane emissions. Industrial compostable bioplastics require high-temperature facilities reaching 55-60degC, accelerating decomposition and ensuring complete breakdown without microplastic residues. Environmental impacts differ as home composting offers accessible, low-energy waste management, while industrial composting provides more controlled conditions for thorough biodegradation, minimizing soil and water contamination risks.

Suitable Bioplastics for Home Composting

Home compostable bioplastics, such as PLA (polylactic acid) and starch blends, are designed to break down effectively in lower temperature and less controlled environments typical of household compost bins. These materials degrade through microbial activity within 90 to 180 days under ambient conditions, making them suitable for organic waste management at home. Unlike industrial compostable bioplastics, which require high heat and humidity, home compostable bioplastics support sustainable waste reduction without specialized composting facilities.

Common Industrial Composting Processes for Bioplastics

Industrial composting of bioplastics occurs under controlled conditions involving higher temperatures (typically 50-70degC), optimized humidity, and aeration to accelerate microbial degradation. Common processes such as aerobic composting, including aerobic thermophilic composting and mechanical-biological treatment (MBT), facilitate the breakdown of bioplastics like PLA and PHA within 6 to 12 weeks. These processes ensure thorough decomposition that is not achievable in home composting due to the absence of such regulated environmental parameters.

Challenges with Home Compostable Bioplastics

Home compostable bioplastics face challenges such as inconsistent degradation rates due to varying household composting conditions, including temperature fluctuations and limited microbial activity. These materials often require longer timeframes to break down fully, which can lead to residue accumulation and contamination in compost. Furthermore, distinguishing between home and industrial compostable bioplastics poses difficulties for consumers, causing improper disposal and reducing overall composting efficiency.

Labeling and Consumer Awareness in Compostable Products

Home compostable bioplastics are designed to break down in backyard compost bins at lower temperatures, but their labeling often lacks clarity, causing consumer confusion. Industrial compostable products require specific conditions like higher heat and controlled humidity, clearly indicated by certifications such as EN 13432, which enhances consumer trust and proper disposal. Effective labeling with recognized certifications boosts consumer awareness, ensuring correct composting practices and reducing contamination in compost streams.

Future Trends in Compostable Bioplastic Packaging

Future trends in compostable bioplastic packaging emphasize the shift toward materials that are compatible with both home and industrial composting systems to enhance environmental benefits. Increasing innovation in polymer blends and additives aims to improve biodegradability under diverse composting conditions, enabling wider consumer adoption and waste reduction. Regulatory frameworks and certification standards are evolving to support transparent labeling and facilitate market growth for truly compostable packaging solutions.

Home compostable vs Industrial compostable Infographic

materialdif.com

materialdif.com