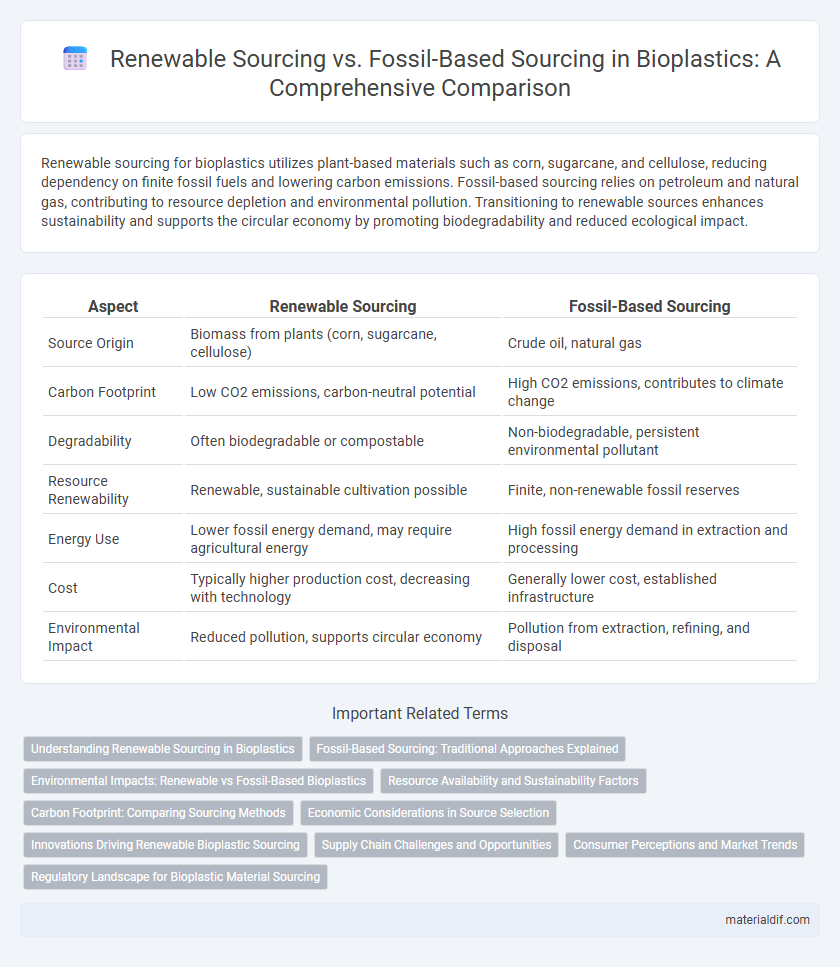

Renewable sourcing for bioplastics utilizes plant-based materials such as corn, sugarcane, and cellulose, reducing dependency on finite fossil fuels and lowering carbon emissions. Fossil-based sourcing relies on petroleum and natural gas, contributing to resource depletion and environmental pollution. Transitioning to renewable sources enhances sustainability and supports the circular economy by promoting biodegradability and reduced ecological impact.

Table of Comparison

| Aspect | Renewable Sourcing | Fossil-Based Sourcing |

|---|---|---|

| Source Origin | Biomass from plants (corn, sugarcane, cellulose) | Crude oil, natural gas |

| Carbon Footprint | Low CO2 emissions, carbon-neutral potential | High CO2 emissions, contributes to climate change |

| Degradability | Often biodegradable or compostable | Non-biodegradable, persistent environmental pollutant |

| Resource Renewability | Renewable, sustainable cultivation possible | Finite, non-renewable fossil reserves |

| Energy Use | Lower fossil energy demand, may require agricultural energy | High fossil energy demand in extraction and processing |

| Cost | Typically higher production cost, decreasing with technology | Generally lower cost, established infrastructure |

| Environmental Impact | Reduced pollution, supports circular economy | Pollution from extraction, refining, and disposal |

Understanding Renewable Sourcing in Bioplastics

Renewable sourcing in bioplastics involves obtaining raw materials from sustainably grown biomass such as corn, sugarcane, or cellulose, which reduces dependence on fossil fuels and lowers carbon footprints. This approach promotes circular economy principles by utilizing feedstocks that can be replenished annually, contrasting with finite fossil-based resources that contribute to greenhouse gas emissions. Understanding renewable sourcing highlights the lifecycle benefits of bioplastics, including reduced environmental impact and enhanced biodegradability compared to conventional plastics derived from petroleum.

Fossil-Based Sourcing: Traditional Approaches Explained

Fossil-based sourcing for bioplastics primarily relies on petrochemical feedstocks such as crude oil and natural gas, which undergo extensive refining and polymerization processes to produce conventional plastics like polyethylene and polypropylene. These methods are highly energy-intensive, contributing significantly to greenhouse gas emissions and environmental pollution. Despite their environmental drawbacks, fossil-based plastics offer consistent material properties and cost advantages that have maintained their dominance in global plastic manufacturing.

Environmental Impacts: Renewable vs Fossil-Based Bioplastics

Renewable sourcing of bioplastics significantly reduces greenhouse gas emissions compared to fossil-based counterparts, as it utilizes biomass from plants that absorb CO2 during growth. Fossil-based bioplastics rely on finite petroleum resources and contribute to higher carbon footprints and environmental pollution. The biodegradability and lower toxicity of renewable bioplastics further minimize ecological damage, making them a more sustainable choice for reducing plastic waste and environmental impact.

Resource Availability and Sustainability Factors

Bioplastics derived from renewable sources such as corn, sugarcane, and cellulose offer greater sustainability by utilizing abundant, replenishable biomass, reducing reliance on finite fossil fuels. Fossil-based plastics depend on oil and natural gas, whose extraction and processing contribute significantly to environmental degradation and greenhouse gas emissions. Renewable sourcing promotes circular economy principles by enabling biodegradability and lower carbon footprints, whereas fossil-based sourcing faces challenges of resource depletion and long-term ecological impact.

Carbon Footprint: Comparing Sourcing Methods

Bioplastics derived from renewable sources like corn, sugarcane, or cellulose typically exhibit a significantly lower carbon footprint compared to fossil-based plastics, as they sequester atmospheric CO2 during biomass growth. Fossil-based sourcing relies on extraction and refining of petroleum, which releases substantial greenhouse gases, contributing to climate change. Life cycle analyses demonstrate that renewable sourcing can reduce carbon emissions by up to 70% relative to conventional fossil-based counterparts, making bioplastics a crucial component in sustainable material development.

Economic Considerations in Source Selection

Renewable sourcing in bioplastics often incurs higher upfront costs due to agricultural inputs and land use but benefits from long-term price stability and reduced exposure to fossil fuel market volatility. Fossil-based sourcing typically offers lower immediate costs with established supply chains, yet it faces increasing price fluctuations linked to crude oil markets and potential carbon regulation penalties. Economic considerations in source selection must balance initial investment, market risk, and evolving policy incentives favoring sustainable materials.

Innovations Driving Renewable Bioplastic Sourcing

Innovations in renewable bioplastic sourcing are rapidly advancing through breakthroughs in feedstock development, such as utilizing agricultural residues, algae, and microbial fermentation, which significantly reduce reliance on fossil-based materials. Cutting-edge enzymatic and genetic engineering techniques enhance the efficiency and yield of biopolymers like polylactic acid (PLA) and polyhydroxyalkanoates (PHA) from renewable resources. These technological advancements not only improve sustainability by lowering carbon footprints but also enable scalable, cost-effective bioplastic production that competes with conventional fossil-derived plastics.

Supply Chain Challenges and Opportunities

Renewable sourcing of bioplastics presents supply chain challenges including variability in raw material availability and seasonal fluctuations impacting consistent feedstock supply. Opportunities arise from integrating agricultural byproducts and waste streams, reducing reliance on fossil fuels and enhancing sustainability credentials. Fossil-based sourcing offers stable supply chains but faces increasing regulatory pressures and environmental concerns driving a shift towards bio-based alternatives.

Consumer Perceptions and Market Trends

Consumer perceptions increasingly favor bioplastics derived from renewable sourcing due to growing environmental awareness and demand for sustainable products. Market trends indicate a shift as renewable-based bioplastics gain higher acceptance, driven by certification standards and eco-labeling that enhance transparency and trust. Fossil-based plastics face declining preference, influenced by regulatory pressures and consumer concerns about carbon footprints and resource depletion.

Regulatory Landscape for Bioplastic Material Sourcing

Regulatory frameworks increasingly favor renewable sourcing for bioplastics, with policies such as the European Union's Single-Use Plastics Directive mandating higher biobased content to reduce carbon footprints. Governments worldwide implement incentives and standards, including the U.S. Biobased Markets Program, to promote sustainable material sourcing and limit fossil-based plastic production. Compliance with evolving regulations drives industry shifts toward bio-renewable feedstocks, reinforcing sustainable supply chains in bioplastic manufacturing.

Renewable sourcing vs Fossil-based sourcing Infographic

materialdif.com

materialdif.com