Oxo-biodegradable plastics degrade through a process initiated by oxidation, breaking down into micro-fragments before microbial activity completes biodegradation, whereas hydro-biodegradable plastics rely primarily on hydrolysis and enzymatic action to decompose directly into water, carbon dioxide, and biomass. Oxo-biodegradable materials may leave microplastic residues if not fully degraded, posing environmental concerns, while hydro-biodegradable plastics tend to mineralize more completely under suitable conditions. Understanding the distinction helps in selecting bioplastics with desired end-of-life scenarios for reducing pollution and enhancing sustainability.

Table of Comparison

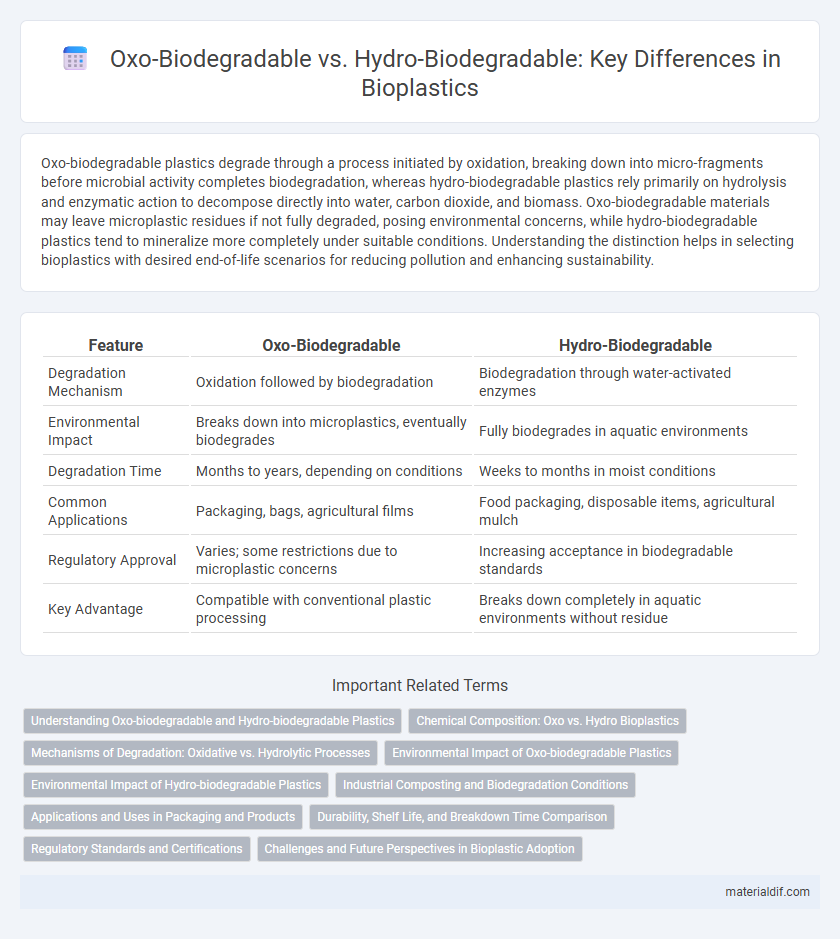

| Feature | Oxo-Biodegradable | Hydro-Biodegradable |

|---|---|---|

| Degradation Mechanism | Oxidation followed by biodegradation | Biodegradation through water-activated enzymes |

| Environmental Impact | Breaks down into microplastics, eventually biodegrades | Fully biodegrades in aquatic environments |

| Degradation Time | Months to years, depending on conditions | Weeks to months in moist conditions |

| Common Applications | Packaging, bags, agricultural films | Food packaging, disposable items, agricultural mulch |

| Regulatory Approval | Varies; some restrictions due to microplastic concerns | Increasing acceptance in biodegradable standards |

| Key Advantage | Compatible with conventional plastic processing | Breaks down completely in aquatic environments without residue |

Understanding Oxo-biodegradable and Hydro-biodegradable Plastics

Oxo-biodegradable plastics contain additives that trigger oxidation under heat or UV light, breaking down the plastic into smaller fragments before microbial degradation begins. Hydro-biodegradable plastics break down primarily through water absorption, enabling microbes to decompose the material more efficiently in aquatic environments. Understanding the distinct degradation pathways and environmental impacts of oxo-biodegradable versus hydro-biodegradable plastics is crucial for selecting suitable bioplastics based on disposal conditions and sustainability goals.

Chemical Composition: Oxo vs. Hydro Bioplastics

Oxo-biodegradable plastics contain conventional polymers blended with metal catalysts such as cobalt or manganese that promote oxidation, breaking down the polymer chains upon exposure to UV light and heat. Hydro-biodegradable plastics are primarily composed of natural polymers like starch or cellulose, which undergo enzymatic hydrolysis in moist environments, leading to microbial assimilation. The chemical composition differences dictate their degradation mechanisms, with oxo-based plastics relying on abiotic oxidation and hydro-based plastics depending on biotic enzymatic activity for biodegradation.

Mechanisms of Degradation: Oxidative vs. Hydrolytic Processes

Oxo-biodegradable plastics degrade primarily through oxidative processes where exposure to oxygen and UV light causes polymer chain scission, leading to fragmentation before microbial assimilation. Hydro-biodegradable plastics rely on hydrolytic degradation, where water molecules break ester bonds in the polymer backbone, resulting in soluble oligomers that microorganisms can metabolize. These distinct mechanisms influence environmental conditions, with oxo-biodegradation favoring aerobic settings and hydro-biodegradation effective in both aerobic and anaerobic environments.

Environmental Impact of Oxo-biodegradable Plastics

Oxo-biodegradable plastics break down through oxidation triggered by UV light and oxygen, resulting in microplastics that persist in the environment and contribute to pollution. These plastics release potentially harmful additives and fragments that can enter ecosystems, affecting soil and marine life negatively. In contrast, hydro-biodegradable plastics decompose primarily through microbial activity, leading to more complete mineralization and reduced ecological toxicity.

Environmental Impact of Hydro-biodegradable Plastics

Hydro-biodegradable plastics break down through the action of water and microbial enzymes, resulting in less microplastic pollution compared to oxo-biodegradable plastics, which fragment into smaller plastic particles before degrading. The environmental impact of hydro-biodegradable plastics is significantly lower, as they convert into carbon dioxide, water, and biomass without leaving persistent residues in soil or marine environments. This improved biodegradation process supports ecosystem health by reducing plastic accumulation and enhancing soil quality.

Industrial Composting and Biodegradation Conditions

Oxo-biodegradable plastics degrade through oxidative processes accelerated by additives, but often require specific industrial composting conditions with controlled temperature and oxygen levels to fully biodegrade, which may be inconsistent in standard facilities. Hydro-biodegradable plastics rely on hydrolysis, breaking down faster under industrial composting environments characterized by high humidity and microbial activity, promoting efficient biodegradation. Industrial composting facilities provide optimal conditions such as temperatures above 55degC and moisture control, critical for complete biodegradation of hydro-biodegradable plastics compared to the slower and more variable breakdown rate of oxo-biodegradable materials.

Applications and Uses in Packaging and Products

Oxo-biodegradable plastics are commonly used in single-use packaging such as shopping bags and agricultural mulch films due to their ability to degrade under exposure to oxygen and sunlight, breaking down into micro-fragments before biodegradation. Hydro-biodegradable plastics, often derived from natural polymers like starch or cellulose, are widely applied in food packaging, compostable bags, and disposable cutlery, where rapid breakdown in aqueous environments or industrial composting conditions is critical. The choice between oxo- and hydro-biodegradable materials depends on specific requirements for biodegradation environment, regulatory standards, and the intended product lifecycle in packaging applications.

Durability, Shelf Life, and Breakdown Time Comparison

Oxo-biodegradable plastics incorporate metal additives that promote fragmentation upon exposure to oxygen, resulting in quicker breakdown but reduced long-term durability and shelf life compared to hydro-biodegradable plastics, which rely on microbial activity and water to decompose. Hydro-biodegradable plastics typically maintain structural integrity longer during storage and use, offering extended shelf life and higher durability under normal conditions. Breakdown time for oxo-biodegradable materials ranges from several months to two years, whereas hydro-biodegradable plastics can take from a few months up to several years depending on environmental moisture and microbial presence.

Regulatory Standards and Certifications

Oxo-biodegradable plastics often face stricter regulatory scrutiny due to concerns about microplastic residue and lack of standardized certification, with entities like the European Union restricting their use in favor of more consistent biodegradability benchmarks. Hydro-biodegradable plastics comply with certifications such as ASTM D6400 and EN 13432, which mandate complete biodegradation under industrial composting conditions within specified timeframes, ensuring meeting international regulatory standards. Regulatory bodies prioritize hydro-biodegradable plastics for their verified environmental performance, influencing global adoption and market access.

Challenges and Future Perspectives in Bioplastic Adoption

Oxo-biodegradable plastics face challenges due to their reliance on additives that can lead to microplastic pollution, raising environmental concerns and regulatory restrictions. Hydro-biodegradable plastics, while more environmentally friendly, require specific composting conditions often unavailable in natural settings, limiting their biodegradation efficiency. Advancements in enzyme engineering and biopolymer formulation are crucial for overcoming these limitations and enhancing the sustainable adoption of bioplastics in various industries.

Oxo-biodegradable vs Hydro-biodegradable Infographic

materialdif.com

materialdif.com