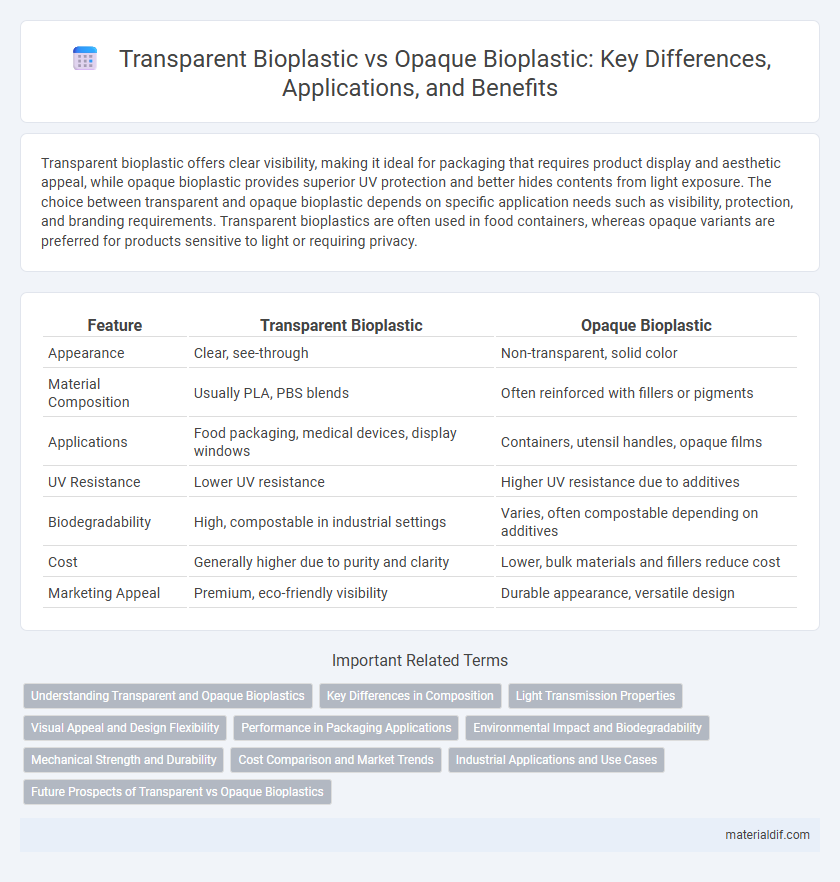

Transparent bioplastic offers clear visibility, making it ideal for packaging that requires product display and aesthetic appeal, while opaque bioplastic provides superior UV protection and better hides contents from light exposure. The choice between transparent and opaque bioplastic depends on specific application needs such as visibility, protection, and branding requirements. Transparent bioplastics are often used in food containers, whereas opaque variants are preferred for products sensitive to light or requiring privacy.

Table of Comparison

| Feature | Transparent Bioplastic | Opaque Bioplastic |

|---|---|---|

| Appearance | Clear, see-through | Non-transparent, solid color |

| Material Composition | Usually PLA, PBS blends | Often reinforced with fillers or pigments |

| Applications | Food packaging, medical devices, display windows | Containers, utensil handles, opaque films |

| UV Resistance | Lower UV resistance | Higher UV resistance due to additives |

| Biodegradability | High, compostable in industrial settings | Varies, often compostable depending on additives |

| Cost | Generally higher due to purity and clarity | Lower, bulk materials and fillers reduce cost |

| Marketing Appeal | Premium, eco-friendly visibility | Durable appearance, versatile design |

Understanding Transparent and Opaque Bioplastics

Transparent bioplastics offer clear visibility and are commonly used in packaging that requires product display, composed primarily of polylactic acid (PLA) and cellulose-based materials. Opaque bioplastics, often made from polyhydroxyalkanoates (PHA) or starch blends, provide more durability and UV resistance, making them suitable for applications like food containers and agricultural films. Understanding the material composition and functional benefits of each type is crucial for selecting the appropriate bioplastic in sustainable design and manufacturing.

Key Differences in Composition

Transparent bioplastics are primarily composed of polylactic acid (PLA) or polyhydroxyalkanoates (PHA), which allow for light transmission due to their molecular arrangement and crystallinity. Opaque bioplastics often contain higher levels of fillers, pigments, or natural fibers such as cellulose or starch, creating a denser structure that blocks light passage. The variation in polymer types and additive concentrations fundamentally influences the optical properties and biodegradability profiles of these materials.

Light Transmission Properties

Transparent bioplastic exhibits high light transmission properties, allowing more than 90% of visible light to pass through, ideal for applications requiring clarity such as packaging and optical devices. Opaque bioplastic, by contrast, blocks light transmission effectively, providing better UV protection and privacy, suitable for containers and insulation materials. The choice between transparent and opaque bioplastic depends on the specific need for light permeability and environmental factors in the intended use.

Visual Appeal and Design Flexibility

Transparent bioplastics offer superior visual appeal by allowing clear visibility of the product inside, enhancing consumer trust and product attractiveness. Opaque bioplastics provide greater design flexibility with the ability to incorporate diverse colors and patterns, offering brands more creative freedom for packaging aesthetics. Both types support eco-friendly initiatives but cater to different marketing and functional needs based on visual and design preferences.

Performance in Packaging Applications

Transparent bioplastics offer superior clarity and aesthetic appeal, making them ideal for packaging that requires product visibility and consumer attraction. Opaque bioplastics provide enhanced UV protection and better barrier properties against moisture and gases, extending shelf life for sensitive products. Performance in packaging is determined by the specific application needs, with transparent bioplastics favored for display purposes and opaque bioplastics chosen for durability and protection.

Environmental Impact and Biodegradability

Transparent bioplastics often utilize materials like PLA (polylactic acid) that offer high biodegradability under industrial composting conditions, reducing long-term environmental pollution. Opaque bioplastics may incorporate fillers or additives that enhance mechanical properties but can impede biodegradation rates, potentially increasing environmental persistence. Selecting transparent bioplastics generally supports more efficient recycling and composting processes, leading to lower carbon footprints and minimized ecological impact.

Mechanical Strength and Durability

Transparent bioplastics, often made from materials like cellulose or polylactic acid (PLA), exhibit moderate mechanical strength with enhanced clarity but can be more susceptible to UV degradation and mechanical wear. Opaque bioplastics typically incorporate fillers or pigments that improve their mechanical strength and durability, making them better suited for structural applications requiring impact resistance. The choice between transparent and opaque bioplastics depends largely on balancing optical properties with the need for enhanced mechanical performance and longevity.

Cost Comparison and Market Trends

Transparent bioplastic typically incurs higher production costs due to the use of refined polymer blends and additives required for clarity, whereas opaque bioplastics benefit from lower raw material expenses and simpler manufacturing processes. Market trends indicate a growing demand for transparent bioplastics in packaging and consumer goods driven by sustainability and aesthetic preferences, while opaque bioplastics maintain steady demand in agriculture and automotive industries due to their cost-effectiveness and durability. Cost comparison studies reveal transparent bioplastics cost approximately 20-30% more than opaque variants, influencing purchasing decisions based on application requirements and budget constraints.

Industrial Applications and Use Cases

Transparent bioplastics are widely used in packaging applications such as food containers, medical devices, and consumer electronics due to their clarity and ability to showcase product contents. Opaque bioplastics find industrial use in automotive parts, agricultural films, and construction materials where durability and UV resistance are critical. Both types support sustainability goals in manufacturing by reducing reliance on fossil fuels and minimizing environmental impact in various sectors.

Future Prospects of Transparent vs Opaque Bioplastics

Transparent bioplastics offer significant potential for packaging and display applications due to their clarity and aesthetic appeal, driving innovation in consumer-facing products. Opaque bioplastics excel in UV protection and mechanical strength, making them ideal for agricultural and industrial uses where durability is critical. Future developments will likely focus on enhancing the biodegradability and cost-efficiency of both types, with transparent bioplastics benefiting from advancements in clarity and barrier properties, and opaque variants improving in environmental resistance and functional additives.

Transparent bioplastic vs Opaque bioplastic Infographic

materialdif.com

materialdif.com