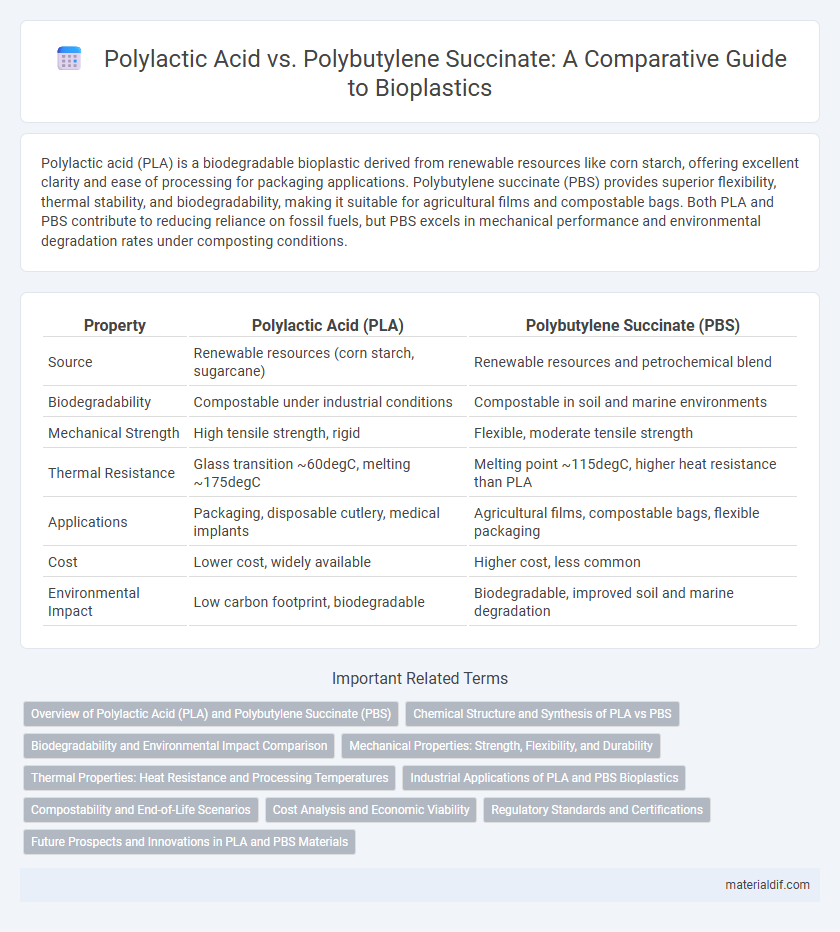

Polylactic acid (PLA) is a biodegradable bioplastic derived from renewable resources like corn starch, offering excellent clarity and ease of processing for packaging applications. Polybutylene succinate (PBS) provides superior flexibility, thermal stability, and biodegradability, making it suitable for agricultural films and compostable bags. Both PLA and PBS contribute to reducing reliance on fossil fuels, but PBS excels in mechanical performance and environmental degradation rates under composting conditions.

Table of Comparison

| Property | Polylactic Acid (PLA) | Polybutylene Succinate (PBS) |

|---|---|---|

| Source | Renewable resources (corn starch, sugarcane) | Renewable resources and petrochemical blend |

| Biodegradability | Compostable under industrial conditions | Compostable in soil and marine environments |

| Mechanical Strength | High tensile strength, rigid | Flexible, moderate tensile strength |

| Thermal Resistance | Glass transition ~60degC, melting ~175degC | Melting point ~115degC, higher heat resistance than PLA |

| Applications | Packaging, disposable cutlery, medical implants | Agricultural films, compostable bags, flexible packaging |

| Cost | Lower cost, widely available | Higher cost, less common |

| Environmental Impact | Low carbon footprint, biodegradable | Biodegradable, improved soil and marine degradation |

Overview of Polylactic Acid (PLA) and Polybutylene Succinate (PBS)

Polylactic Acid (PLA) is a biodegradable thermoplastic derived from renewable resources such as corn starch or sugarcane, known for its high tensile strength and rigidity, making it suitable for packaging and disposable products. Polybutylene Succinate (PBS) is a biodegradable aliphatic polyester synthesized from succinic acid and 1,4-butanediol, offering excellent thermal stability, flexibility, and compostability, often used in agricultural films and disposable items. Both PLA and PBS contribute to reducing plastic pollution by providing sustainable alternatives to conventional petroleum-based plastics.

Chemical Structure and Synthesis of PLA vs PBS

Polylactic acid (PLA) is a biodegradable polyester synthesized through the ring-opening polymerization of lactide, a cyclic dimer of lactic acid, featuring a linear aliphatic backbone with ester linkages contributing to its rigidity. Polybutylene succinate (PBS) is produced via polycondensation of succinic acid and 1,4-butanediol, exhibiting a flexible aliphatic polyester chain with repeating butylene and succinate units that enhance its toughness. The chemical structure differences between PLA and PBS result from their synthesis routes, where PLA's lactide-derived stereochemistry affects crystallinity, while PBS's combination of diacid and diol imparts superior thermal and mechanical properties.

Biodegradability and Environmental Impact Comparison

Polylactic acid (PLA) biodegrades under industrial composting conditions within 1 to 6 months, reducing landfill accumulation and producing minimal greenhouse gas emissions compared to conventional plastics. Polybutylene succinate (PBS) exhibits faster biodegradability in various environments, including soil and marine settings, breaking down within weeks to a few months while generating less toxic residues. PBS's enhanced environmental impact profile makes it a preferred choice for applications requiring rapid decomposition and minimal ecological footprint.

Mechanical Properties: Strength, Flexibility, and Durability

Polylactic acid (PLA) exhibits high tensile strength and rigidity but has limited flexibility and lower impact resistance, making it suitable for rigid packaging applications. Polybutylene succinate (PBS) offers superior flexibility and elongation at break, with enhanced toughness and durability, ideal for applications requiring repeated bending or stretching. Both bioplastics degrade under composting conditions, but PBS maintains mechanical integrity better under humid environments due to its higher thermal and impact resistance.

Thermal Properties: Heat Resistance and Processing Temperatures

Polylactic acid (PLA) exhibits a lower heat resistance with a glass transition temperature around 60degC and melting point near 170degC, limiting its use in high-temperature applications. Polybutylene succinate (PBS) offers superior thermal stability, with a higher melting point around 115degC and a heat deflection temperature close to 85degC, enabling better performance in heat-resistant products. Processing temperatures for PLA range between 180-220degC, whereas PBS typically requires 120-150degC, making PBS more suitable for applications needing moderate thermal resistance and flexible processing.

Industrial Applications of PLA and PBS Bioplastics

Polylactic acid (PLA) is widely used in packaging, disposable tableware, and biomedical devices due to its biodegradability and high clarity, making it ideal for food contact and medical applications. Polybutylene succinate (PBS) exhibits superior thermal stability and flexibility, which suits it for agricultural films, compostable bags, and durable molded products. Both bioplastics serve critical roles in sustainable industrial applications, with PLA favored for rigid items and PBS preferred for flexible and high-performance uses.

Compostability and End-of-Life Scenarios

Polylactic acid (PLA) exhibits high compostability under industrial composting conditions, typically breaking down within 1-3 months, while polybutylene succinate (PBS) demonstrates broader biodegradability in both industrial and home compost environments. PLA requires precise temperature and humidity control for effective degradation, limiting its end-of-life scenarios mainly to industrial composting facilities. In contrast, PBS can biodegrade in soil, marine environments, and home composts, offering more versatile and environmentally sustainable disposal options.

Cost Analysis and Economic Viability

Polylactic acid (PLA) generally exhibits lower production costs due to established fermentation processes and readily available corn starch feedstock, making it more economically viable for large-scale applications. Polybutylene succinate (PBS) production involves more complex synthesis routes using succinic acid and 1,4-butanediol, which elevates its manufacturing costs and limits competitive pricing in comparison to PLA. Market trends indicate PLA's dominant position in packaging and disposable products driven by cost efficiency, while PBS remains niche due to higher costs despite favorable mechanical properties.

Regulatory Standards and Certifications

Polylactic acid (PLA) complies with FDA approval for food contact applications and meets EN 13432 standards for compostability, making it suitable for packaging and disposable items. Polybutylene succinate (PBS) is recognized under ASTM D6400 for industrial compostability and adheres to EU Biodegradability criteria, offering robust performance in biodegradable agricultural films. Both bioplastics are certified by organizations like TUV Austria and DIN CERTCO, ensuring compliance with global regulatory standards for sustainability and safety.

Future Prospects and Innovations in PLA and PBS Materials

Polylactic acid (PLA) and polybutylene succinate (PBS) are rapidly evolving with advancements in biopolymer synthesis and biodegradable composites, driving their future prospects in sustainable packaging and agriculture. Innovations in PLA focus on enhancing thermal resistance and mechanical properties through copolymerization and blending, expanding its application range beyond single-use plastics. Meanwhile, PBS development targets improved biodegradability and compatibility with microbe-driven composting systems, positioning it as a promising candidate for eco-friendly mulch films and disposable items.

Polylactic acid vs Polybutylene succinate Infographic

materialdif.com

materialdif.com