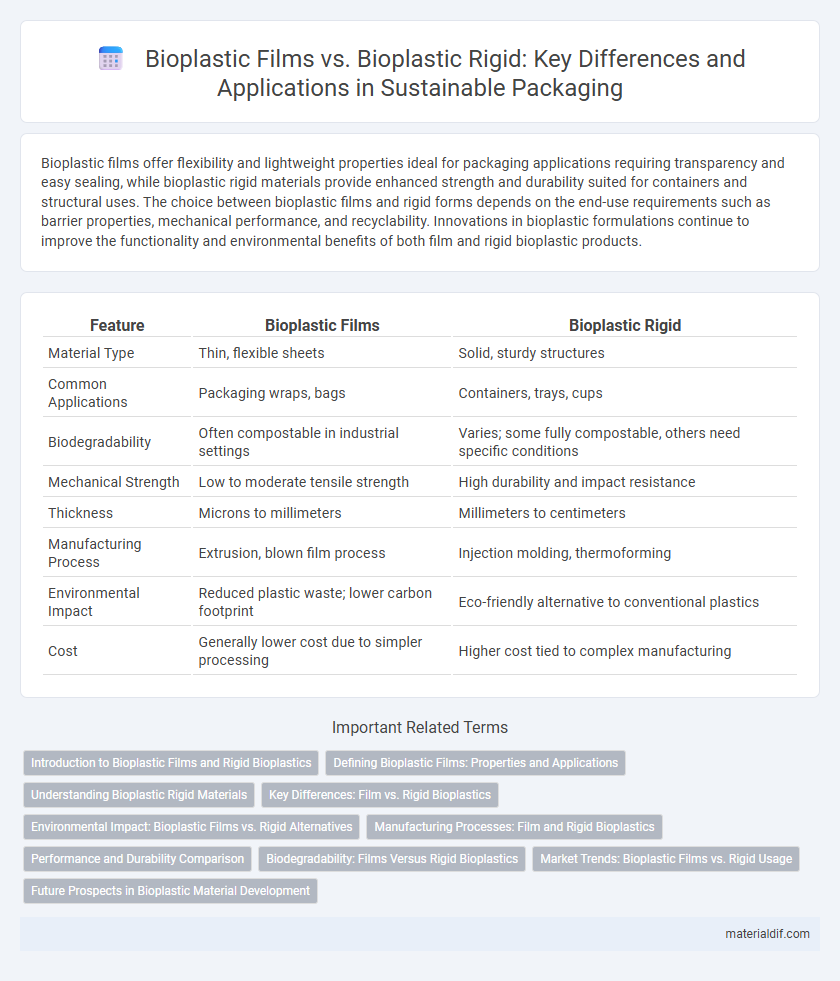

Bioplastic films offer flexibility and lightweight properties ideal for packaging applications requiring transparency and easy sealing, while bioplastic rigid materials provide enhanced strength and durability suited for containers and structural uses. The choice between bioplastic films and rigid forms depends on the end-use requirements such as barrier properties, mechanical performance, and recyclability. Innovations in bioplastic formulations continue to improve the functionality and environmental benefits of both film and rigid bioplastic products.

Table of Comparison

| Feature | Bioplastic Films | Bioplastic Rigid |

|---|---|---|

| Material Type | Thin, flexible sheets | Solid, sturdy structures |

| Common Applications | Packaging wraps, bags | Containers, trays, cups |

| Biodegradability | Often compostable in industrial settings | Varies; some fully compostable, others need specific conditions |

| Mechanical Strength | Low to moderate tensile strength | High durability and impact resistance |

| Thickness | Microns to millimeters | Millimeters to centimeters |

| Manufacturing Process | Extrusion, blown film process | Injection molding, thermoforming |

| Environmental Impact | Reduced plastic waste; lower carbon footprint | Eco-friendly alternative to conventional plastics |

| Cost | Generally lower cost due to simpler processing | Higher cost tied to complex manufacturing |

Introduction to Bioplastic Films and Rigid Bioplastics

Bioplastic films are thin, flexible sheets made from biodegradable polymers such as PLA or PHA, commonly used in packaging applications for their lightweight and compostable properties. Rigid bioplastics, produced from materials like starch-based blends or bio-PET, offer durable and sturdy structures ideal for containers, bottles, and trays. Both forms leverage renewable resources and contribute to reducing plastic pollution by providing sustainable alternatives to conventional petroleum-based plastics.

Defining Bioplastic Films: Properties and Applications

Bioplastic films are thin, flexible sheets made from renewable polymers such as polylactic acid (PLA) or polyhydroxyalkanoates (PHA), known for their biodegradability and strong barrier properties against moisture and gases. These films are widely used in packaging applications, including food wraps, agricultural mulch films, and single-use bags, where flexibility and transparency are crucial. Their ability to decompose quickly in industrial composting conditions positions bioplastic films as sustainable alternatives to conventional polyethylene films in reducing plastic pollution.

Understanding Bioplastic Rigid Materials

Bioplastic rigid materials offer enhanced durability and structural integrity compared to bioplastic films, making them ideal for packaging applications requiring strength and protection. These rigid bioplastics, often derived from polylactic acid (PLA) or starch-based polymers, provide excellent barrier properties and resistance to moisture and oils. Understanding the mechanical properties and biodegradability of rigid bioplastics is crucial for optimizing their use in eco-friendly product packaging and reducing plastic waste.

Key Differences: Film vs. Rigid Bioplastics

Bioplastic films are thin, flexible materials primarily used for packaging applications such as food wraps and bags, offering moisture resistance and breathability. In contrast, bioplastic rigid products, like containers and bottles, provide structural strength, durability, and shape retention for use in storage and transport. The key differences lie in their mechanical properties, thickness, and typical end-use applications, with films emphasizing flexibility and rigidity favoring sturdiness.

Environmental Impact: Bioplastic Films vs. Rigid Alternatives

Bioplastic films typically have a lower carbon footprint compared to bioplastic rigid alternatives due to reduced material usage and energy consumption during production. However, bioplastic rigid products generally offer better durability and recyclability, contributing to longer product lifespans and reduced waste generation. Life cycle assessments reveal that both forms can significantly lower environmental impacts relative to conventional plastics, depending on factors such as feedstock source, end-of-life treatment, and manufacturing processes.

Manufacturing Processes: Film and Rigid Bioplastics

Bioplastic films are typically manufactured using extrusion processes such as blown film extrusion or cast film extrusion, allowing thin, flexible sheets ideal for packaging applications. In contrast, bioplastic rigid products are produced through injection molding, thermoforming, or compression molding, enabling the creation of durable, solid shapes like containers and trays. The choice of manufacturing method significantly influences the mechanical properties and application scope of bioplastic materials in sustainable packaging solutions.

Performance and Durability Comparison

Bioplastic films exhibit flexible properties suitable for packaging applications requiring lightweight and transparency, but they generally offer lower tensile strength and durability compared to bioplastic rigid materials. Bioplastic rigid products provide superior impact resistance, structural integrity, and long-term stability, making them ideal for containers and durable goods. Performance differences arise from varying polymer compositions and processing methods, directly influencing mechanical strength and environmental resistance.

Biodegradability: Films Versus Rigid Bioplastics

Bioplastic films generally exhibit faster biodegradability due to their thin structure and higher surface area, facilitating microbial breakdown under composting conditions. In contrast, bioplastic rigid materials decompose more slowly because of their thicker, denser form, which limits microbial access and oxygen diffusion. The biodegradation rate of both depends significantly on polymer composition, environmental factors, and processing methods.

Market Trends: Bioplastic Films vs. Rigid Usage

Bioplastic films dominate the packaging sector due to their flexibility, lightweight properties, and cost-effectiveness, with market growth driven by demand for sustainable food wrapping and agricultural applications. In contrast, bioplastic rigid products are gaining traction in durable goods, automotive, and electronics industries, fueled by advancements in material strength and consumer preference for eco-friendly alternatives. Market analysis reveals that while films hold a larger share, rigid bioplastics exhibit higher CAGR, reflecting a significant shift towards diversified bioplastic solutions across different industries.

Future Prospects in Bioplastic Material Development

Bioplastic films are expected to advance significantly through enhanced barrier properties and biodegradability, making them ideal for flexible packaging applications. Bioplastic rigid materials will see innovations in mechanical strength and thermal resistance, broadening their use in durable goods and automotive components. Future development emphasizes sustainable sourcing and cost-efficiency to promote widespread adoption across industries.

Bioplastic films vs Bioplastic rigid Infographic

materialdif.com

materialdif.com