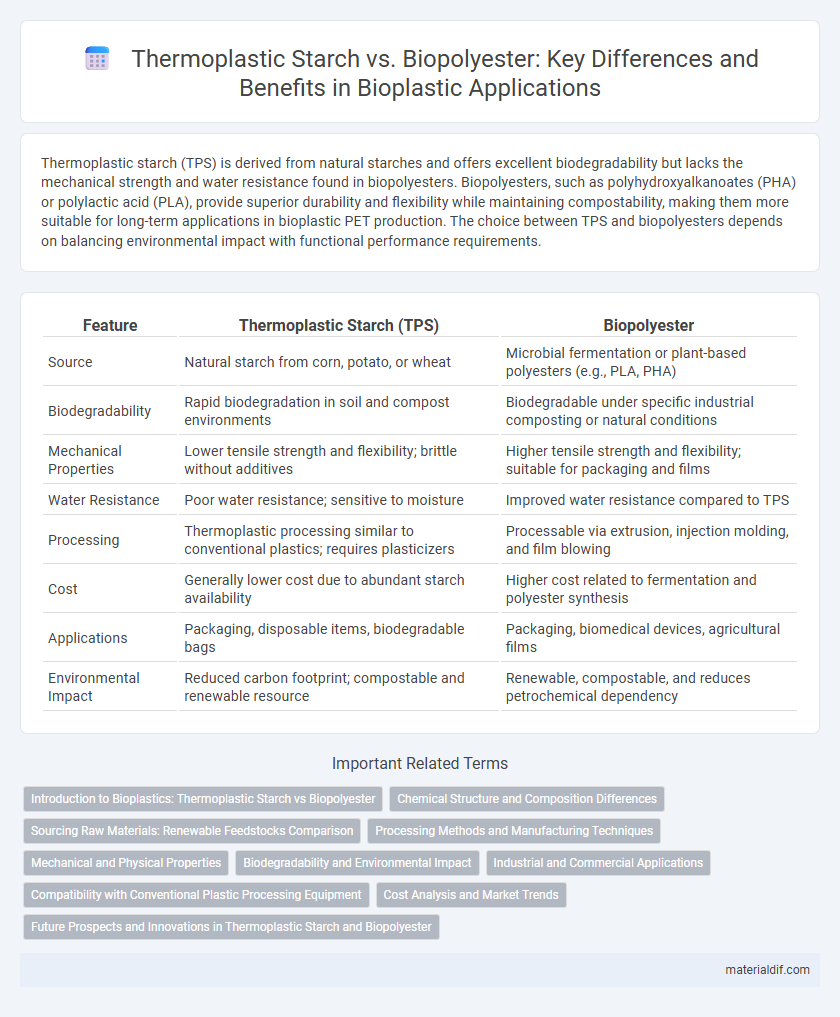

Thermoplastic starch (TPS) is derived from natural starches and offers excellent biodegradability but lacks the mechanical strength and water resistance found in biopolyesters. Biopolyesters, such as polyhydroxyalkanoates (PHA) or polylactic acid (PLA), provide superior durability and flexibility while maintaining compostability, making them more suitable for long-term applications in bioplastic PET production. The choice between TPS and biopolyesters depends on balancing environmental impact with functional performance requirements.

Table of Comparison

| Feature | Thermoplastic Starch (TPS) | Biopolyester |

|---|---|---|

| Source | Natural starch from corn, potato, or wheat | Microbial fermentation or plant-based polyesters (e.g., PLA, PHA) |

| Biodegradability | Rapid biodegradation in soil and compost environments | Biodegradable under specific industrial composting or natural conditions |

| Mechanical Properties | Lower tensile strength and flexibility; brittle without additives | Higher tensile strength and flexibility; suitable for packaging and films |

| Water Resistance | Poor water resistance; sensitive to moisture | Improved water resistance compared to TPS |

| Processing | Thermoplastic processing similar to conventional plastics; requires plasticizers | Processable via extrusion, injection molding, and film blowing |

| Cost | Generally lower cost due to abundant starch availability | Higher cost related to fermentation and polyester synthesis |

| Applications | Packaging, disposable items, biodegradable bags | Packaging, biomedical devices, agricultural films |

| Environmental Impact | Reduced carbon footprint; compostable and renewable resource | Renewable, compostable, and reduces petrochemical dependency |

Introduction to Bioplastics: Thermoplastic Starch vs Biopolyester

Thermoplastic starch (TPS) is derived from renewable resources such as corn, wheat, or potato starch and is biodegradable, making it a sustainable option for disposable packaging. Biopolyesters like polylactic acid (PLA) are synthesized through microbial fermentation of sugars, offering superior mechanical properties and compostability compared to TPS. The choice between TPS and biopolyester depends on application requirements, environmental impact, and end-of-life options for bioplastics.

Chemical Structure and Composition Differences

Thermoplastic starch is primarily composed of amylose and amylopectin polymers derived from natural starch, which undergo modification with plasticizers like glycerol to enhance flexibility, resulting in a polysaccharide-based structure. Biopolyesters, such as polylactic acid (PLA) and polyhydroxyalkanoates (PHA), consist of ester-linked repeating units derived from hydroxy acid monomers through microbial fermentation or chemical synthesis, featuring more hydrophobic chains and higher crystallinity. The fundamental chemical difference lies in thermoplastic starch's carbohydrate backbone versus biopolyesters' aliphatic polyester chains, influencing their biodegradability, mechanical properties, and processing behavior.

Sourcing Raw Materials: Renewable Feedstocks Comparison

Thermoplastic starch is primarily sourced from abundant renewable feedstocks such as corn, potato, and tapioca, offering a cost-effective and biodegradable option derived from natural crops. Biopolyesters, including polylactic acid (PLA) and polyhydroxyalkanoates (PHA), are produced from fermentation of sugars sourced from renewable biomass like sugarcane, corn starch, and other plant-based materials, providing diverse functional properties. The choice between thermoplastic starch and biopolyesters depends on feedstock availability, production costs, and desired material characteristics for sustainable bioplastic applications.

Processing Methods and Manufacturing Techniques

Thermoplastic starch is processed primarily through extrusion and injection molding, utilizing heat and shear to transform starch-based materials into flexible, moldable products, making it suitable for large-scale manufacturing with lower energy consumption. Biopolyesters, such as polyhydroxyalkanoates (PHA) or polylactic acid (PLA), require more complex polymerization processes followed by standard thermoplastic processing techniques including injection molding, blow molding, and film extrusion, offering higher thermal stability and strength. Both materials benefit from advancements in reactive extrusion and compounding methods to enhance material properties and processing efficiency in sustainable bioplastic production.

Mechanical and Physical Properties

Thermoplastic starch (TPS) exhibits lower tensile strength and elongation at break compared to biopolyesters, making it less durable for high-stress applications. Biopolyesters, such as polyhydroxyalkanoates (PHA) and polylactic acid (PLA), provide superior mechanical properties, including higher impact resistance and flexibility. TPS shows higher moisture absorption and lower thermal stability, whereas biopolyesters maintain structural integrity under a wider range of temperatures and environmental conditions.

Biodegradability and Environmental Impact

Thermoplastic starch (TPS) exhibits rapid biodegradability in soil and compost environments due to its natural polysaccharide structure, breaking down within weeks without leaving toxic residues. Biopolyesters, such as polylactic acid (PLA) and polyhydroxyalkanoates (PHA), offer slower but more controlled biodegradation, contributing to reduced greenhouse gas emissions during their lifecycle. TPS has a lower environmental impact in terms of resource use and carbon footprint but may have limitations in mechanical properties, whereas biopolyesters provide better durability with moderate biodegradability and improved end-of-life sustainability.

Industrial and Commercial Applications

Thermoplastic starch (TPS) offers cost-effective solutions in packaging and disposable items, benefiting from its biodegradability and renewability in industrial applications. Biopolyesters, such as polylactic acid (PLA) and polyhydroxyalkanoates (PHA), provide superior mechanical strength and thermal resistance, making them suitable for reusable containers, fibers, and medical devices in commercial sectors. Both materials contribute to sustainable product development, with TPS favored for short-term use and biopolyesters optimized for durability and performance.

Compatibility with Conventional Plastic Processing Equipment

Thermoplastic starch exhibits high compatibility with conventional plastic processing equipment such as injection molding and extrusion machines due to its similar melting behavior and processing temperatures. Biopolyesters, including polylactic acid (PLA) and polyhydroxyalkanoates (PHA), require precise temperature control and more specialized processing conditions, which may limit their seamless integration into existing plastic manufacturing lines. The compatibility of thermoplastic starch with standard equipment facilitates cost-effective production and easier adoption in industries aiming to reduce reliance on fossil-based plastics.

Cost Analysis and Market Trends

Thermoplastic starch (TPS) typically offers lower production costs due to abundant raw materials like corn and potatoes, making it attractive for price-sensitive markets. Biopolyesters, such as polylactic acid (PLA) and polyhydroxyalkanoates (PHA), tend to have higher costs attributed to complex fermentation processes and polymerization, yet benefit from stronger mechanical properties and biodegradability. Market trends show increasing demand for biopolyesters in packaging and medical applications, driven by consumer preference and regulatory support, while TPS remains prevalent in disposable items where cost efficiency is critical.

Future Prospects and Innovations in Thermoplastic Starch and Biopolyester

Thermoplastic starch (TPS) and biopolyesters both show promising future prospects in sustainable materials, with TPS benefiting from innovations in starch modification and blending techniques to enhance mechanical properties and water resistance. Biopolyesters, such as polylactic acid (PLA) and polyhydroxyalkanoates (PHA), are advancing through bio-based monomer synthesis and improved biodegradability under diverse environmental conditions. Emerging research emphasizes developing hybrid materials combining TPS and biopolyesters to optimize performance, reduce costs, and expand applications in packaging and biomedical fields.

Thermoplastic starch vs Biopolyester Infographic

materialdif.com

materialdif.com