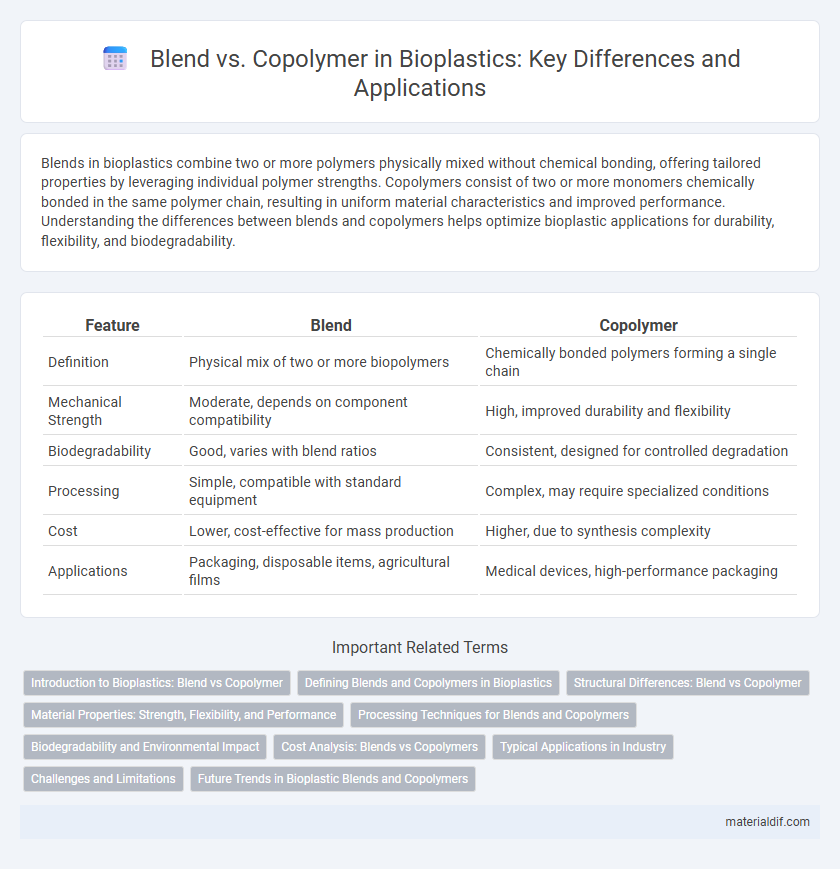

Blends in bioplastics combine two or more polymers physically mixed without chemical bonding, offering tailored properties by leveraging individual polymer strengths. Copolymers consist of two or more monomers chemically bonded in the same polymer chain, resulting in uniform material characteristics and improved performance. Understanding the differences between blends and copolymers helps optimize bioplastic applications for durability, flexibility, and biodegradability.

Table of Comparison

| Feature | Blend | Copolymer |

|---|---|---|

| Definition | Physical mix of two or more biopolymers | Chemically bonded polymers forming a single chain |

| Mechanical Strength | Moderate, depends on component compatibility | High, improved durability and flexibility |

| Biodegradability | Good, varies with blend ratios | Consistent, designed for controlled degradation |

| Processing | Simple, compatible with standard equipment | Complex, may require specialized conditions |

| Cost | Lower, cost-effective for mass production | Higher, due to synthesis complexity |

| Applications | Packaging, disposable items, agricultural films | Medical devices, high-performance packaging |

Introduction to Bioplastics: Blend vs Copolymer

Bioplastics often utilize blends and copolymers to enhance material properties such as flexibility, strength, and biodegradability. Blends combine two or more distinct biopolymers physically mixed to achieve tailored characteristics, while copolymers chemically bond different monomer units within a single polymer chain for more uniform performance. Understanding the differences between blend and copolymer bioplastics is crucial for optimizing their application in sustainable packaging, agriculture, and medical industries.

Defining Blends and Copolymers in Bioplastics

Blends in bioplastics refer to physical mixtures of two or more polymers combined to enhance performance, offering tailored mechanical and thermal properties without chemical bonding. Copolymers consist of two or more different monomers chemically bonded within the same polymer chain, providing unique structural features and improved material characteristics. Understanding the distinction between blends and copolymers is crucial for optimizing bioplastic applications in packaging, agriculture, and automotive industries.

Structural Differences: Blend vs Copolymer

Blends are physical mixtures of two or more distinct polymers combined to enhance material properties without altering their individual molecular structures. Copolymers consist of two or more different monomers chemically bonded in a single polymer chain, resulting in a uniform molecular architecture with tailored characteristics. The key structural difference lies in blends maintaining separate polymer phases, whereas copolymers form integrated chains with varied monomer sequences affecting crystallinity, mechanical strength, and biodegradability.

Material Properties: Strength, Flexibility, and Performance

Blend bioplastics combine two or more polymers, offering enhanced flexibility and toughness by leveraging the individual strengths of each component, which results in improved impact resistance and processability. Copolymer bioplastics consist of chemically bonded monomers within a single polymer chain, providing superior strength and uniform mechanical properties due to the consistent molecular structure. Performance differences manifest in blend bioplastics excelling in applications requiring elasticity, while copolymers are preferred for high-strength, dimensionally stable products.

Processing Techniques for Blends and Copolymers

Processing techniques for bioplastic blends often involve melt blending, extrusion, and injection molding, allowing compatibility between different polymer components to be enhanced through compatibilizers. Copolymers require precise control during polymerization methods such as reactive extrusion or solution polymerization to achieve uniform distribution of monomer units and desired mechanical properties. Optimized processing parameters for both blends and copolymers ensure improved thermal stability, flexibility, and biodegradability tailored for specific application requirements.

Biodegradability and Environmental Impact

Blends of bioplastics combine multiple polymer types, often enhancing mechanical properties but sometimes reducing biodegradability due to incompatible components that hinder microbial breakdown. Copolymers are designed at the molecular level to integrate monomers, resulting in more uniform structures that typically exhibit improved biodegradability and reduced environmental impact compared to blends. Choosing copolymers over blends can lead to faster decomposition rates and lower ecological footprints in composting and natural environments.

Cost Analysis: Blends vs Copolymers

Blends of bioplastics typically offer lower production costs due to the use of readily available raw materials and simpler processing techniques, making them a cost-effective option for large-scale applications. Copolymers, while more expensive to produce because of complex polymerization processes and precise monomer control, deliver enhanced performance attributes that justify their higher price in specialized uses. Cost analysis reveals blends are preferred for budget-sensitive projects, whereas copolymers are selected when durability and functionality outweigh initial investment concerns.

Typical Applications in Industry

Blends of bioplastics combine two or more polymers to optimize mechanical properties and cost-efficiency, commonly used in packaging, agriculture films, and disposable cutlery. Copolymers, featuring chemically bonded monomers, offer enhanced barrier properties and flexibility, making them ideal for food packaging, medical devices, and automotive components. The choice between blends and copolymers depends on specific industry requirements such as durability, biodegradability, and performance under stress.

Challenges and Limitations

Blends of bioplastics often face challenges in achieving uniform compatibility, leading to phase separation and diminished mechanical properties that limit their application range. Copolymers, while offering improved material consistency and performance by chemically linking different monomers, present difficulties in synthesis complexity and higher production costs. Both approaches struggle with balancing biodegradability and durability, which restricts their scalability in commercial markets.

Future Trends in Bioplastic Blends and Copolymers

Future trends in bioplastic blends and copolymers emphasize enhanced material performance through synergistic combinations of polymers such as PLA, PHA, and PBAT, optimizing mechanical strength and biodegradability. Innovations in compatibilizers and reactive blending techniques promote improved interfacial adhesion and processability, expanding applications in packaging, agriculture, and medical devices. Advancements in bio-based monomers and catalyst technologies drive sustainable copolymer synthesis with tailored properties, supporting circular economy goals and regulatory compliance.

Blend vs Copolymer Infographic

materialdif.com

materialdif.com