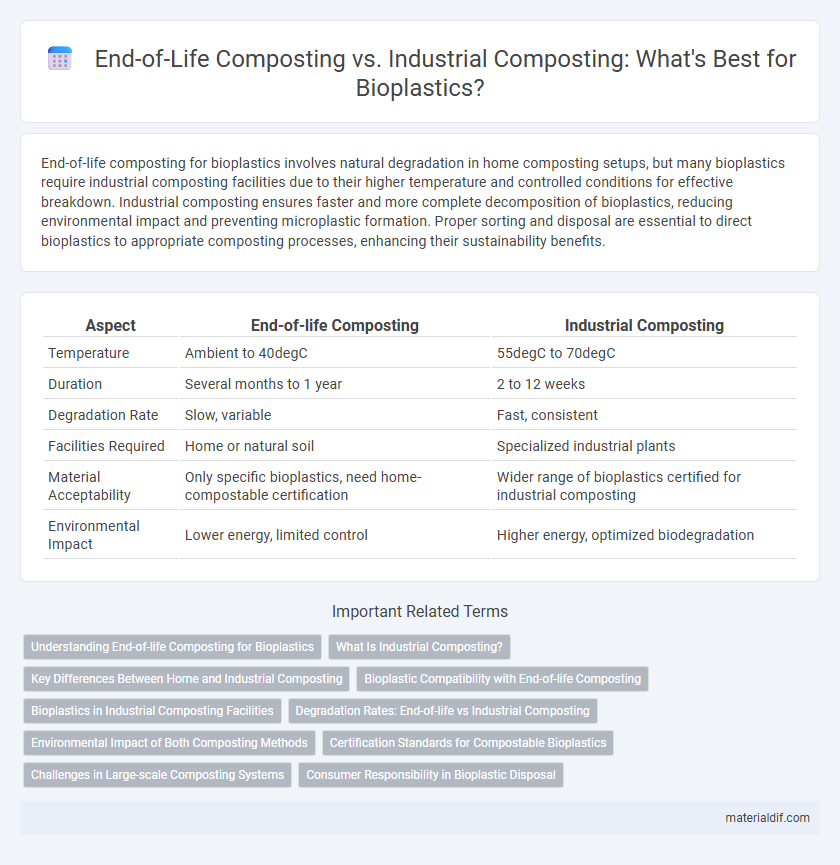

End-of-life composting for bioplastics involves natural degradation in home composting setups, but many bioplastics require industrial composting facilities due to their higher temperature and controlled conditions for effective breakdown. Industrial composting ensures faster and more complete decomposition of bioplastics, reducing environmental impact and preventing microplastic formation. Proper sorting and disposal are essential to direct bioplastics to appropriate composting processes, enhancing their sustainability benefits.

Table of Comparison

| Aspect | End-of-life Composting | Industrial Composting |

|---|---|---|

| Temperature | Ambient to 40degC | 55degC to 70degC |

| Duration | Several months to 1 year | 2 to 12 weeks |

| Degradation Rate | Slow, variable | Fast, consistent |

| Facilities Required | Home or natural soil | Specialized industrial plants |

| Material Acceptability | Only specific bioplastics, need home-compostable certification | Wider range of bioplastics certified for industrial composting |

| Environmental Impact | Lower energy, limited control | Higher energy, optimized biodegradation |

Understanding End-of-life Composting for Bioplastics

End-of-life composting for bioplastics involves the biological decomposition of materials into nutrient-rich compost under specific conditions. Industrial composting facilities maintain controlled temperature, humidity, and aeration to ensure efficient breakdown of bioplastics, typically requiring temperatures above 58degC for several weeks. Home composting differs by relying on natural microbial activity at ambient temperatures, often leading to slower or incomplete bioplastic degradation without industrial composting infrastructure.

What Is Industrial Composting?

Industrial composting is a high-temperature process designed to break down bioplastics and organic waste in controlled environments, typically reaching temperatures of 55-60degC to accelerate decomposition. Unlike end-of-life home composting, industrial composting facilities use specialized aeration, moisture control, and microbial activity to ensure complete biodegradation of bioplastics within weeks to months. This method is essential for managing bioplastics that do not readily decompose in home compost conditions, supporting sustainable waste management and reducing landfill accumulation.

Key Differences Between Home and Industrial Composting

End-of-life composting of bioplastics varies significantly between home and industrial settings, primarily due to temperature, microbial activity, and time requirements. Industrial composting facilities maintain controlled high temperatures (55-60degC) that accelerate bioplastic degradation within weeks, while home composting environments often lack sufficient heat, resulting in slower or incomplete breakdown. Key distinctions include the scalability of processes, presence of specialized microbes, and regulation compliance, which ensure industrial composting meets stringent biodegradability standards not guaranteed in typical home compost setups.

Bioplastic Compatibility with End-of-life Composting

Bioplastic compatibility with end-of-life composting varies significantly between home and industrial settings due to differences in temperature, microbial activity, and processing time. Industrial composting facilities maintain elevated temperatures of 55-70degC and optimized conditions that accelerate the biodegradation of bioplastics like PLA and PHA within weeks, whereas home composting environments often lack sufficient heat and microbial diversity, leading to incomplete breakdown over months. Selecting bioplastics specifically certified for home composting, such as certain starch-based polymers, ensures effective biodegradability in backyard compost systems, enhancing their environmental benefits.

Bioplastics in Industrial Composting Facilities

Bioplastics designed for industrial composting require specific conditions such as controlled temperature (typically 58degC or higher), humidity, and microbial activity that are maintained in industrial composting facilities but rarely achievable in home composting environments. Industrial composting facilities can efficiently break down certified compostable bioplastics within 90 to 180 days, converting them into nutrient-rich compost without leaving harmful residues. The lack of these conditions in end-of-life composting settings often results in incomplete degradation, highlighting the importance of proper waste stream separation and infrastructure to optimize the environmental benefits of bioplastics.

Degradation Rates: End-of-life vs Industrial Composting

End-of-life composting results in slower degradation rates for bioplastics compared to industrial composting, where controlled temperature, humidity, and microbial activity accelerate breakdown processes. Industrial composting facilities can degrade many bioplastics within 90 to 180 days, whereas end-of-life composting environments may require significantly longer periods, sometimes exceeding a year. The efficiency of industrial composting in reducing bioplastic waste highlights the importance of proper waste management infrastructure for optimized environmental impact.

Environmental Impact of Both Composting Methods

End-of-life composting of bioplastics in home compost systems often results in slower degradation and incomplete breakdown, leading to potential microplastic accumulation and limited environmental benefits. Industrial composting facilities maintain higher temperatures and controlled conditions that enable rapid, complete biodegradation, significantly reducing greenhouse gas emissions and soil contamination risks. Efficient industrial composting minimizes residual waste and supports circular economy principles by returning bioplastic materials to the ecosystem as nutrient-rich compost.

Certification Standards for Compostable Bioplastics

Certification standards for compostable bioplastics differentiate end-of-life composting from industrial composting by defining specific temperature, humidity, and time requirements to ensure complete biodegradation. Industrial composting certifications, such as ASTM D6400 and EN 13432, mandate controlled environments reaching 58degC to 60degC over 90 days, whereas home composting standards like OK Compost Home require biodegradability under lower temperatures typical of garden composts. These certifications ensure that bioplastics break down without leaving toxic residues, facilitating proper waste management and environmental sustainability.

Challenges in Large-scale Composting Systems

End-of-life composting of bioplastics faces significant challenges in large-scale composting systems due to varying decomposition rates and contamination risks. Industrial composting facilities require controlled temperature, humidity, and aeration to effectively break down bioplastics, but inconsistent feedstock and mixed waste streams complicate processing. Scaling these systems demands advanced sorting technologies and standardized labeling to ensure bioplastics are correctly identified and composted, preventing environmental pollution and operational disruptions.

Consumer Responsibility in Bioplastic Disposal

End-of-life composting of bioplastics requires consumer awareness that home composting conditions often lack the high temperatures and controlled environment necessary for effective breakdown. Industrial composting facilities provide optimal conditions, such as sustained temperatures above 55degC and regulated humidity, ensuring complete biodegradation of certified bioplastics within a specific timeframe. Proper consumer disposal by segregating bioplastic waste and utilizing designated composting services significantly enhances the environmental benefits of bioplastics, reducing contamination and promoting circular economy practices.

End-of-life composting vs Industrial composting Infographic

materialdif.com

materialdif.com