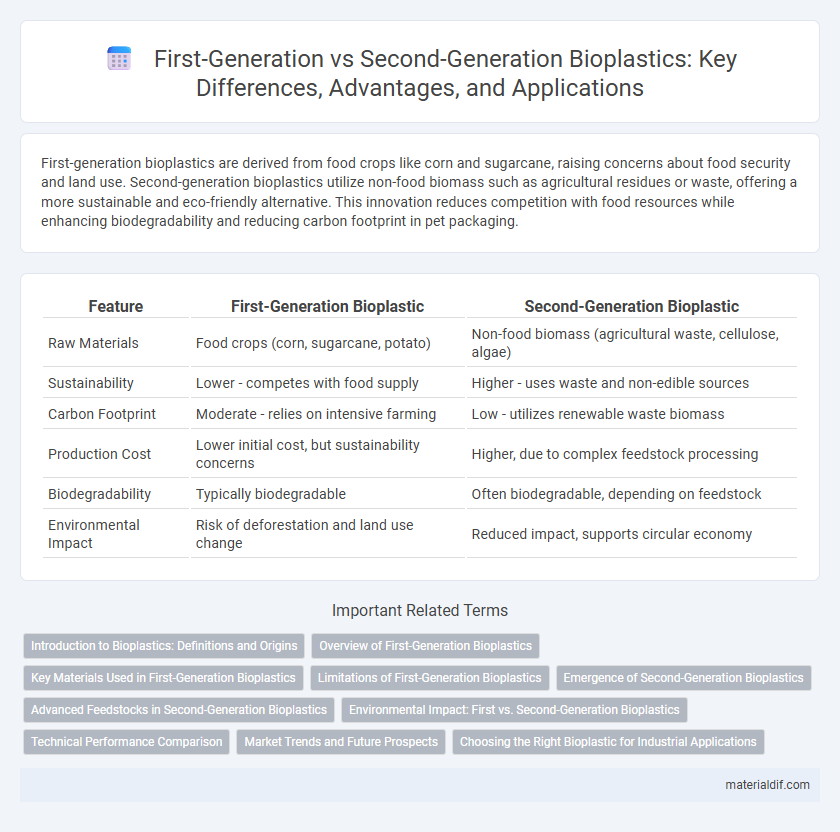

First-generation bioplastics are derived from food crops like corn and sugarcane, raising concerns about food security and land use. Second-generation bioplastics utilize non-food biomass such as agricultural residues or waste, offering a more sustainable and eco-friendly alternative. This innovation reduces competition with food resources while enhancing biodegradability and reducing carbon footprint in pet packaging.

Table of Comparison

| Feature | First-Generation Bioplastic | Second-Generation Bioplastic |

|---|---|---|

| Raw Materials | Food crops (corn, sugarcane, potato) | Non-food biomass (agricultural waste, cellulose, algae) |

| Sustainability | Lower - competes with food supply | Higher - uses waste and non-edible sources |

| Carbon Footprint | Moderate - relies on intensive farming | Low - utilizes renewable waste biomass |

| Production Cost | Lower initial cost, but sustainability concerns | Higher, due to complex feedstock processing |

| Biodegradability | Typically biodegradable | Often biodegradable, depending on feedstock |

| Environmental Impact | Risk of deforestation and land use change | Reduced impact, supports circular economy |

Introduction to Bioplastics: Definitions and Origins

First-generation bioplastics are primarily derived from food crops like corn, sugarcane, and cassava, utilizing starches and sugars for polymer production. Second-generation bioplastics, in contrast, are synthesized from non-food biomass sources such as agricultural residues, lignocellulosic materials, and industrial waste, reducing competition with food resources. The development of second-generation bioplastics aims to enhance sustainability by addressing environmental impacts and improving feedstock accessibility.

Overview of First-Generation Bioplastics

First-generation bioplastics are primarily derived from food crops such as corn, sugarcane, and potatoes, making them rich in starch and sugars suitable for fermentation processes. These bioplastics, including polylactic acid (PLA) and bio-polyethylene, offer renewable alternatives to petroleum-based plastics but raise concerns regarding food security and land use. Production of first-generation bioplastics typically involves well-established agricultural supply chains and biochemical conversion technologies, contributing to their commercial viability.

Key Materials Used in First-Generation Bioplastics

First-generation bioplastics primarily use food crops such as corn, sugarcane, and potato starch as raw materials, relying heavily on edible biomass for polymer production. These bioplastics include polylactic acid (PLA) and starch-based plastics, which are derived from fermenting sugars extracted from these crops. The reliance on food-based feedstocks raises sustainability concerns due to potential competition with food supply and land use.

Limitations of First-Generation Bioplastics

First-generation bioplastics primarily rely on food crops like corn and sugarcane, leading to competition with food supply and concerns about land use. Their limited biodegradability and dependence on agricultural resources contribute to environmental sustainability challenges. High production costs and limited scalability further restrict their widespread adoption compared to second-generation bioplastics derived from non-food biomass.

Emergence of Second-Generation Bioplastics

Second-generation bioplastics emerged as sustainable alternatives to first-generation bioplastics, addressing concerns related to food crop competition and land use by utilizing non-food biomass such as agricultural residues and waste materials. These advanced bioplastics exhibit improved environmental benefits, including reduced greenhouse gas emissions and lower reliance on arable land compared to starch or sugar-based first-generation options. Innovations in feedstock variety and processing technologies have driven the scalability and performance enhancements of second-generation bioplastics, positioning them as a crucial step towards a circular bioeconomy.

Advanced Feedstocks in Second-Generation Bioplastics

Second-generation bioplastics utilize advanced feedstocks such as agricultural residues, non-food crops, and lignocellulosic biomass, reducing competition with food supply chains characteristic of first-generation bioplastics derived from edible crops like corn and sugarcane. These advanced feedstocks offer improved sustainability by leveraging waste materials and fast-growing plants, enhancing carbon sequestration and lowering land-use impacts. Innovations in biotechnology enable efficient conversion of complex polymers in second-generation feedstocks into high-quality bioplastics, driving the development of more environmentally friendly materials.

Environmental Impact: First vs. Second-Generation Bioplastics

First-generation bioplastics, derived primarily from food crops like corn and sugarcane, often compete with food production and require significant land and water resources, leading to higher environmental impacts such as deforestation and greenhouse gas emissions. Second-generation bioplastics utilize non-food biomass, agricultural residues, and waste materials, reducing pressure on food supplies and promoting sustainable land use while minimizing carbon footprints. The shift from first to second-generation bioplastics marks a crucial advancement in lowering ecological damage by enhancing biodegradability and resource efficiency.

Technical Performance Comparison

First-generation bioplastics, primarily derived from food crops like corn and sugarcane, exhibit reliable biodegradability but often face limitations in mechanical strength and thermal resistance compared to conventional plastics. Second-generation bioplastics, produced from non-food biomass such as agricultural residues and waste, demonstrate enhanced technical performance, including improved tensile strength, flexibility, and heat tolerance. Advances in genetic engineering and polymer blending further elevate second-generation bioplastics' suitability for diverse industrial applications.

Market Trends and Future Prospects

First-generation bioplastics, derived primarily from food crops like corn and sugarcane, face market challenges due to competition with food supply and sustainability concerns. Second-generation bioplastics utilize non-food biomass such as agricultural residues and lignocellulosic materials, offering enhanced environmental benefits and scalability. Market trends indicate growing investment and innovation in second-generation bioplastics, driven by regulatory support and increasing demand for eco-friendly materials in packaging and automotive industries.

Choosing the Right Bioplastic for Industrial Applications

First-generation bioplastics are primarily derived from food crops like corn and sugarcane, offering easy availability but competing with food supply and raising sustainability concerns. Second-generation bioplastics utilize non-food biomass such as agricultural residues and waste, providing a more sustainable and environmentally friendly option for industrial applications. Selecting the right bioplastic depends on factors including feedstock availability, production cost, biodegradability, and end-use requirements in the industrial sector.

First-generation bioplastic vs Second-generation bioplastic Infographic

materialdif.com

materialdif.com