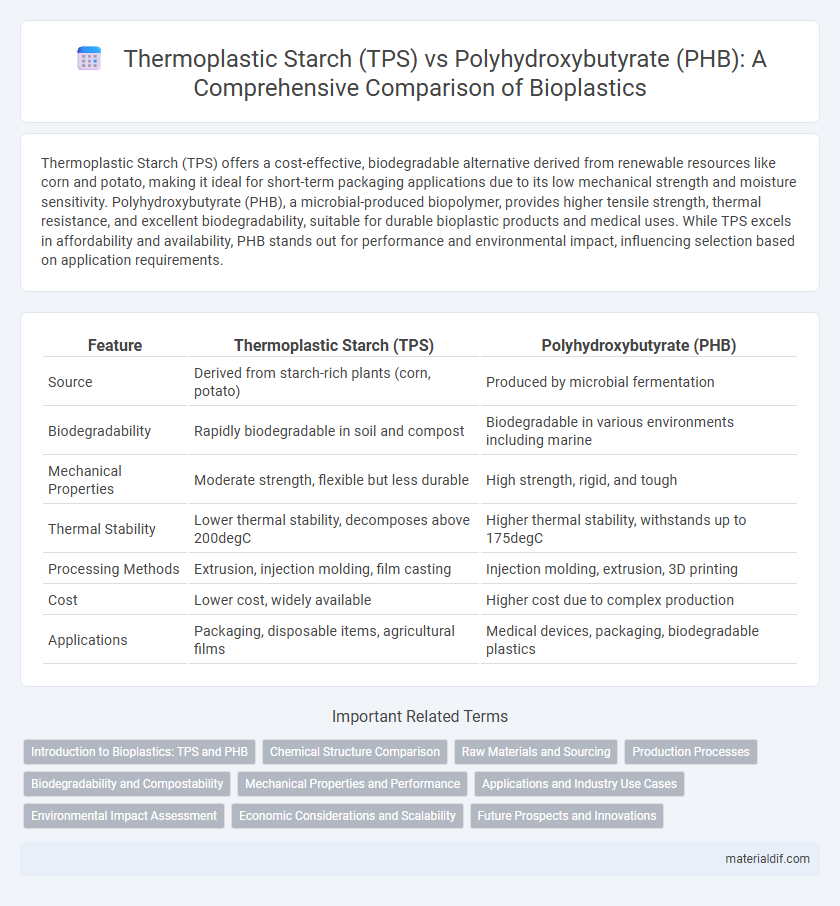

Thermoplastic Starch (TPS) offers a cost-effective, biodegradable alternative derived from renewable resources like corn and potato, making it ideal for short-term packaging applications due to its low mechanical strength and moisture sensitivity. Polyhydroxybutyrate (PHB), a microbial-produced biopolymer, provides higher tensile strength, thermal resistance, and excellent biodegradability, suitable for durable bioplastic products and medical uses. While TPS excels in affordability and availability, PHB stands out for performance and environmental impact, influencing selection based on application requirements.

Table of Comparison

| Feature | Thermoplastic Starch (TPS) | Polyhydroxybutyrate (PHB) |

|---|---|---|

| Source | Derived from starch-rich plants (corn, potato) | Produced by microbial fermentation |

| Biodegradability | Rapidly biodegradable in soil and compost | Biodegradable in various environments including marine |

| Mechanical Properties | Moderate strength, flexible but less durable | High strength, rigid, and tough |

| Thermal Stability | Lower thermal stability, decomposes above 200degC | Higher thermal stability, withstands up to 175degC |

| Processing Methods | Extrusion, injection molding, film casting | Injection molding, extrusion, 3D printing |

| Cost | Lower cost, widely available | Higher cost due to complex production |

| Applications | Packaging, disposable items, agricultural films | Medical devices, packaging, biodegradable plastics |

Introduction to Bioplastics: TPS and PHB

Thermoplastic Starch (TPS) and Polyhydroxybutyrate (PHB) are prominent bioplastics derived from renewable biomass sources, offering sustainable alternatives to traditional petroleum-based plastics. TPS, produced by plasticizing starch from crops like corn or potatoes, is biodegradable, cost-effective, and suitable for short-term applications such as packaging. PHB, a microbial polyester synthesized through bacterial fermentation, provides higher mechanical strength and thermal resistance, making it ideal for more durable bioplastic products.

Chemical Structure Comparison

Thermoplastic Starch (TPS) is derived from starch, a polysaccharide composed of amylose and amylopectin, featuring glucose monomers linked by a-1,4 and a-1,6 glycosidic bonds. Polyhydroxybutyrate (PHB) is a polyester consisting of 3-hydroxybutyrate monomers linked by ester bonds, giving it a semi-crystalline and hydrophobic nature. The key chemical distinction lies in TPS's polysaccharide backbone versus PHB's polyester structure, influencing biodegradability, mechanical properties, and thermal behavior.

Raw Materials and Sourcing

Thermoplastic Starch (TPS) is derived predominantly from abundant, renewable starch sources such as corn, potato, and cassava, making its raw materials widely accessible and cost-effective. Polyhydroxybutyrate (PHB) is produced through bacterial fermentation of sugar or lipids sourced from crops like sugarcane and palm oil, requiring more controlled bioprocessing conditions. The sustainability and supply-chain stability of TPS depend heavily on agricultural starch availability, whereas PHB sourcing involves biochemical extraction with potential fluctuations in microbial feedstock inputs.

Production Processes

Thermoplastic Starch (TPS) is produced by gelatinizing starch granules through heating and shear in the presence of plasticizers, resulting in a moldable thermoplastic material. Polyhydroxybutyrate (PHB) synthesis involves microbial fermentation using specific bacteria like Cupriavidus necator, which accumulate PHB intracellularly as carbon and energy storage. TPS production is generally faster and leverages abundant starch sources, whereas PHB requires longer fermentation times and controlled bioprocessing conditions for polymer extraction and purification.

Biodegradability and Compostability

Thermoplastic Starch (TPS) exhibits high biodegradability and compostability due to its natural polysaccharide structure, breaking down efficiently in both industrial and home composting environments. Polyhydroxybutyrate (PHB), a microbial polyester, offers superior biodegradability under anaerobic and aerobic conditions but requires controlled industrial composting for optimized degradation. Both TPS and PHB contribute significantly to eco-friendly plastic alternatives with TPS favoring rapid breakdown in natural settings and PHB providing durable, biodegradable properties suitable for diverse applications.

Mechanical Properties and Performance

Thermoplastic Starch (TPS) offers moderate tensile strength and flexibility but exhibits lower impact resistance and moisture sensitivity compared to Polyhydroxybutyrate (PHB), which provides higher stiffness, superior barrier properties, and better biodegradability in diverse environments. PHB's mechanical performance suits rigid packaging and agricultural films, while TPS is preferable for applications requiring easy processing and cost-effectiveness. Optimizing blends of TPS and PHB can enhance durability, flexibility, and moisture resistance for advanced bioplastic solutions.

Applications and Industry Use Cases

Thermoplastic Starch (TPS) is widely used in packaging films, disposable tableware, and agricultural mulch films due to its biodegradability, low cost, and ease of processing. Polyhydroxybutyrate (PHB) finds applications in medical implants, controlled drug delivery systems, and high-strength packaging materials, benefiting from its superior mechanical properties and biocompatibility. Industries such as food packaging, agriculture, and biomedical engineering leverage TPS for short-term use products and PHB for durable, environmentally friendly alternatives.

Environmental Impact Assessment

Thermoplastic Starch (TPS) demonstrates a lower carbon footprint due to its renewable, plant-based origin and biodegradability in soil and compost environments, reducing landfill accumulation. Polyhydroxybutyrate (PHB), derived from microbial fermentation, offers superior biodegradation in marine environments and produces less toxic residues compared to conventional plastics. Life cycle assessments reveal TPS requires less energy in production, while PHB's degradation pathways contribute significantly to minimizing microplastic pollution.

Economic Considerations and Scalability

Thermoplastic Starch (TPS) is cost-effective due to its low raw material prices and abundant availability of starch from crops like corn and potatoes, enabling large-scale production with minimal capital investment. Polyhydroxybutyrate (PHB), while biodegradable and offering superior mechanical properties, suffers from higher production costs tied to complex microbial fermentation processes and limited feedstock availability, restricting its economic scalability. TPS's relatively straightforward manufacturing methods promote widespread adoption, whereas PHB requires advances in bioprocess optimization to become economically competitive on an industrial scale.

Future Prospects and Innovations

Thermoplastic Starch (TPS) and Polyhydroxybutyrate (PHB) represent two leading bioplastics with distinct future prospects shaped by ongoing innovations in biodegradability and mechanical properties. Advances in TPS focus on enhancing water resistance and blending with other biopolymers to expand its application range, while PHB research prioritizes cost reduction through microbial fermentation optimization and genetic engineering. Emerging hybrid materials integrating TPS and PHB aim to combine flexibility with durability, driving sustainable alternatives in packaging and agriculture.

Thermoplastic Starch (TPS) vs Polyhydroxybutyrate (PHB) Infographic

materialdif.com

materialdif.com